Designed by Behnisch Architekten, Harvard University’s new Science and Engineering Complex (SEC) is a dynamic lab for research and learning. Its forward-looking design reflects the advanced, world-class spatial and technological solutions of its faculty and staff who are meeting the complex, changing requirements of scientific inquiry. The cornerstone building of the school’s new Allston Campus, located directly across the Charles River from Harvard’s 300-year home in Cambridge, the 544,000-square-foot research and teaching facility housing the School of Engineering and Applied Science (SEAS) sets a distinctive architectural tone for future development in one of Boston’s last undeveloped neighborhoods. Charged with becoming the “healthiest building on the Harvard campus,” the SEC establishes the university’s commitment to sustainability, cutting-edge academic and research activity, and high-quality urban design.

As a relatively new school within the Faculty of Arts and Sciences, SEAS lacked a consolidated footprint and adequate space in Cambridge. The SEC presented the opportunity to locate the majority of the school under one roof with the goal of further fostering an already robust culture of collaboration and interdisciplinary working. Reflecting the evolving, interdisciplinary nature of research, the building is designed to be highly flexible and adaptable, through a series of environments that support collaboration and create vibrant public spaces at a variety of scales. The building was constructed on the existing foundation of a previously-designed life sciences complex that was suspended in 2008. When the project resumed, it was designed to set a strong precedent for the development of outdoor space, street activation, and integration with larger public space networks that are a key part of the university’s master plan for Allston.

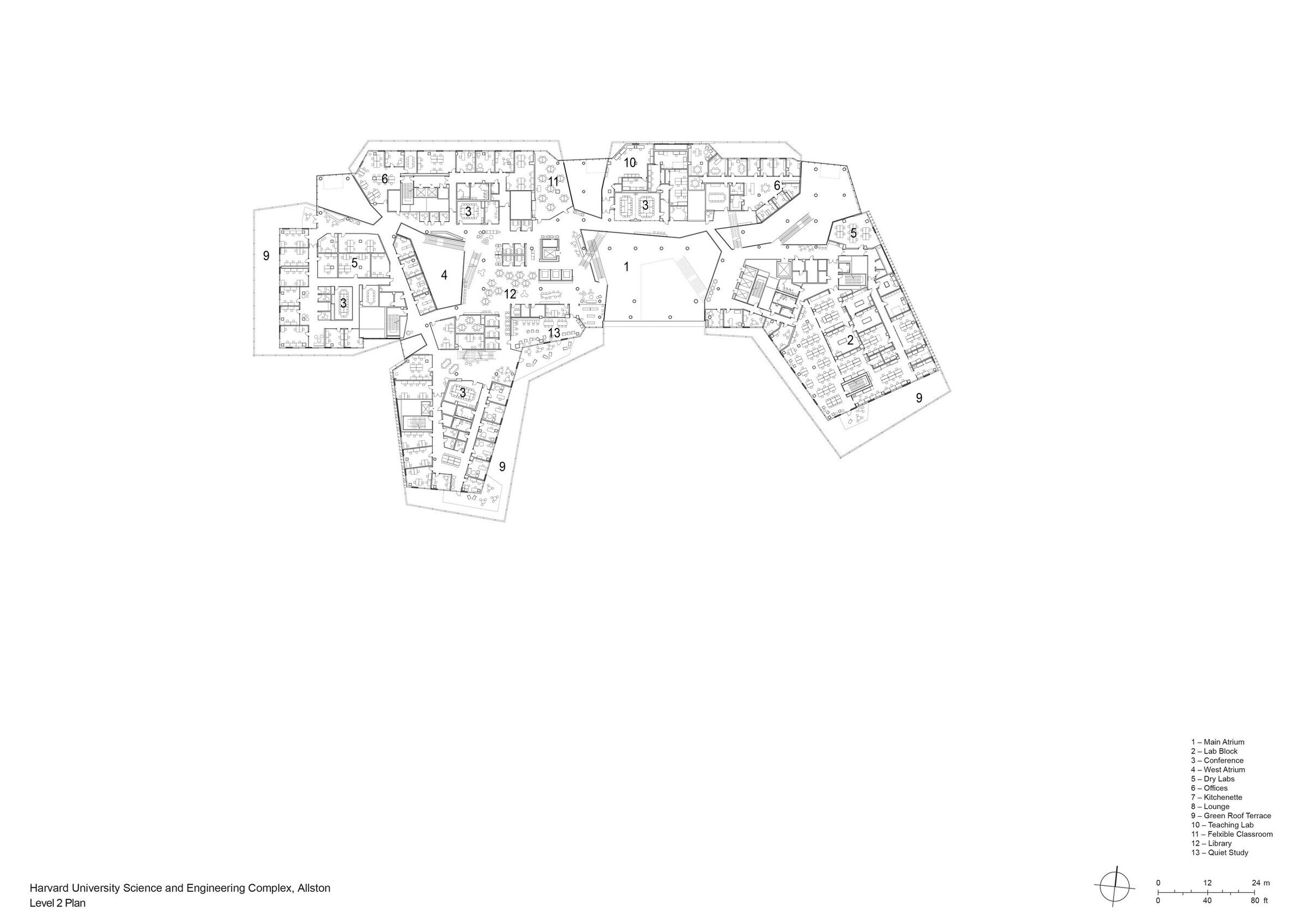

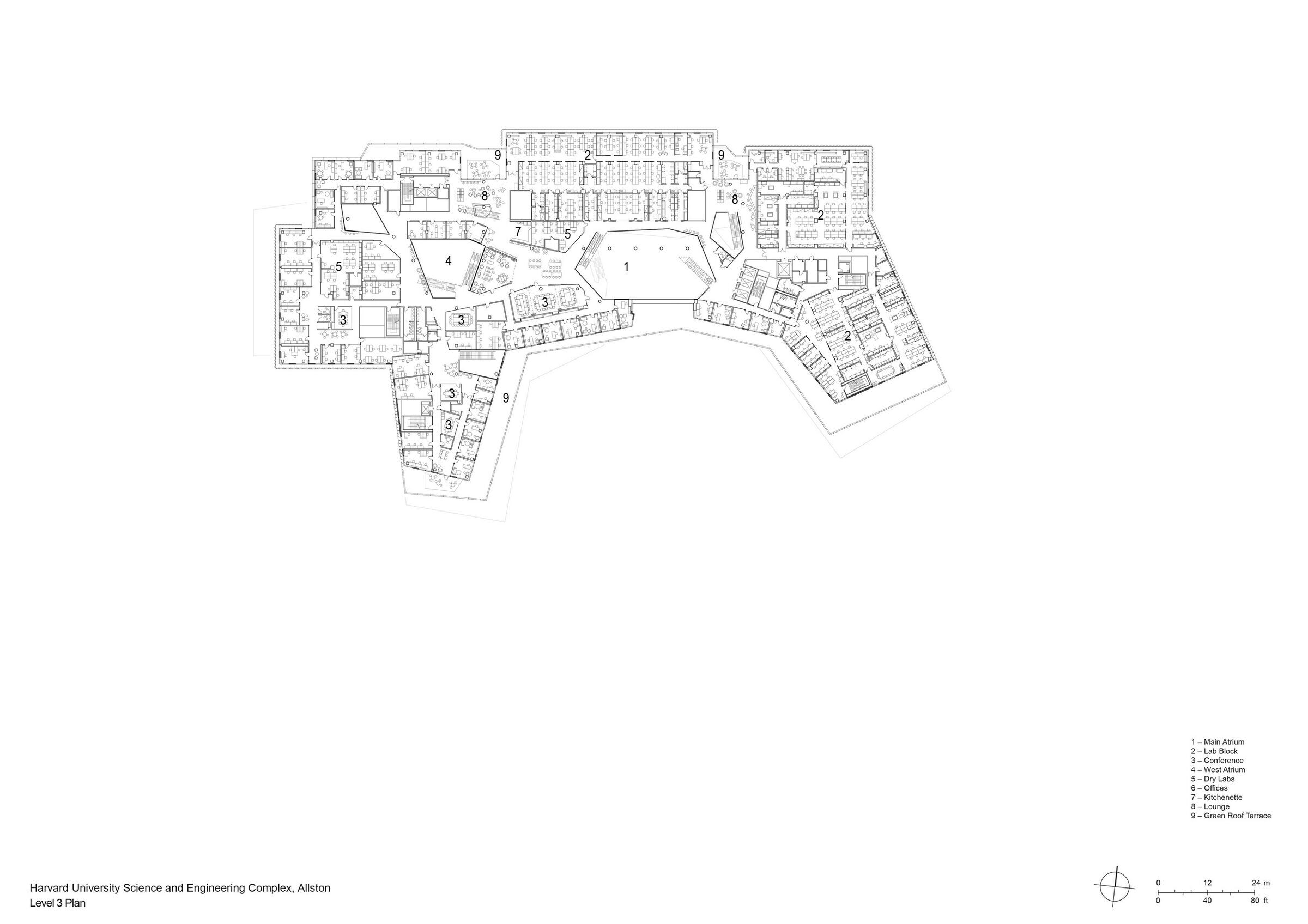

The eight-level SEC is situated prominently along Western Avenue, a primary thoroughfare. The massing weaves together three elevated four-story blocks of laboratories around two atria, allowing the ground floor to be a highly public, communicative zone focused on teaching and collaborative spaces, and providing access to and opening towards the landscaped courtyard at the south. It creates a visual rhythm along the nearly 500 feet of street frontage analogous to more traditionally scaled structures, while maintaining the continuity of the program in a single building. The laboratory blocks are clad in a custom stainless-steel sun-shading screen that provides solar control and daylight enhancement to the staggered fenestration pattern behind it. From the street, the laboratory volumes appear to float above more generously glazed first and second floors which link the public face of the building to the lushly landscaped garden to the south.

An integrated, collaborative plan and program

The building’s organization follows the massing logic, with classrooms, teaching labs, and amenity spaces occupying the lower floors to take advantage of proximity to the street and courtyard, while research labs in the upper volumes maintain appropriate levels of solitude and security. Regularly occupied working spaces line the perimeter of much of the SEC, and are designed as a kind of environmental layer mediating the exterior and interior of the building. These offices, work spaces, and meeting rooms all have operable windows, with transfer mechanisms that allow fresh air to cascade deep into the building and ensure high-quality ventilation during appropriate outdoor conditions. Makerspaces and teaching labs located along Western Avenue showcase the active learning methodologies used by SEAS and engage the community in the work being done by students. Classrooms and meeting spaces are in varying sizes and layouts, ranging from typical, theater-style classrooms with sloped floors and fixed seating to active-learning spaces that can be reconfigured at will to allow for flipped classroom scenarios and student-led discussions.

The upper floors house 69,120 square feet of open wet research laboratory space accommodating biological, chemical, physical, optical, electronics activities, as well as 24,000 square feet of dry research laboratories for computer science researchers. Modular, flexible laboratory environments, smart zoning of highly ventilated zones from dry space, and robust delivery of centralized lab services ensure the future adaptability and continued use of laboratory space for decades to come. Two- and three-story lounges between the laboratory blocks provide connection points and respite for researchers at a more intimate scale. Simple materials such as exposed concrete, glass, and open acoustic ceilings keep the spaces open and flexible, while wooden flooring and stairs, seating areas, work bars, and benches emphasize the areas for collaboration and gathering.

Natural light and air

Two atria flood the interior with daylight and facilitate natural ventilation. The central atrium connects all levels of the building, transitioning from the more public teaching floors to the more private research floors at the upper levels. A large café and a stepped, wood-lined seating area look out to the courtyard and the collaboration spaces at the lower levels, reinforcing the connection of teaching spaces on the building’s lower three floors. The western atrium acts as a secondary organizing element for the building, creating additional spaces for events and collaborative working while daylighting all of the above-grade floors on the western half of the site.

Deep overhangs and fixed horizontal sun-shading define the landscaped terraces, culminating in a series of storm water gardens at ground level that surround the central courtyard. Ventilation rates, typically the strongest driver of laboratory energy consumption, were scrutinized as part of a comprehensive risk assessment to determine appropriate air flow for all spaces in the building, with the goal of reducing ventilation rates by as much as one-third without sacrificing occupant safety.

State-of-the-art sustainability

The SEC is an exemplar of integrated sustainability, in both quantitative as well as qualitative terms, not only for Harvard but also in the US. The project, which has received LEED Platinum and LivingBuildingChallenge (LBC), Petal certification in Materials, Beauty, and Equity, is expected to reduce greenhouse gas emissions by 50% over its comparable baseline building.

The layered design of the façade calibrates the scale of the large volumes that constitute the research program of the building, creates an identity for the complex, and plays a crucial role in the energy performance of the building as well as occupant comfort. Five acres of vegetated roof terraces contribute to thermal comfort and give occupants of the lower floors their own garden views at each level of the building. Behnisch Architekten worked with Transsolar to develop an integrated climate and energy concept with special emphasis on four separate facade concepts, natural ventilation, and laboratory ventilation. Behnisch Architekten and construction manager Turner Construction teamed with Harvard to research over 5,600 individual products and building systems, and secured materials declarations from over 1,500 contracted manufacturers, guaranteeing full transparency in the chemical make-up of the products specified for the project.

The linchpin to the building’s ambitious energy goals, its revolutionary, specialized façade design balances technical and aesthetic goals in a way that celebrates its performance-oriented aspects and makes a strong statement about the university’s presence in Allston. Four principal façade types are used at the building:

• Laboratory Screen Wall: The research areas on the upper floors are sheathed in a sophisticated screen enclosure designed in collaboration with the structural engineering firm of KnippersHelbig. The world’s first hydroformed tensile façade system, it combines solar control with material innovation, using stainless steel that has the delicacy and lightness of fabric. The concept centers on a fixed sunshade screen that is geometrically calibrated to lower peak cooling loads by 65% while reflecting daylight deep into the spaces. The challenge of producing 12,000 precisely-milled panels in 14 different shapes required Josef Gartner GmbH/Permasteelisa North America Corp. to develop highly innovative fabrication techniques.

To maximize structural, material, and fabrication efficiencies, the approach was inspired by utilitarian objects such as soup cans, wheelbarrows, and car bodies. A team of engineers, fabricators, and lighting and climate specialists used empirical testing, rapid prototyping, full-scale visual and performance mockups, and advanced industrial design and simulation software (including CATIA, a 3D modeling software used for the design and visualization of complex, innovative shapes) to optimize the screen panels for strength, production, and visual qualities.

The panels are fabricated from 1.5mm thick stainless steel utilizing a production method known as hydroforming, found commonly in the industrial parts and automotive industries. After folding each panel to achieve structural integrity, the final step—laser cutting along five axes—perforates their edges, blurring the contrast between shade and exterior.The structural stiffness of the panels enabled a minimal tensile support structure, enabling views and daylight to penetrate the interiors. The panel cassette is bolted directly to spring-tensioned vertical steel rods, with only wind bracing at the spandrel levels.

Depending on its exact position on the facade, each screen is precisely dimensioned and machined to shield the building interior from solar heat gain during warmer months, while it lets beneficial sun in during the winter. This significantly reduces cooling and heating loads on the mechanical plant. The screen also reflects daylight towards the interior while maintaining large view apertures to the outside. The thermal enclosure behind the screen is triple-glazed, and punctuated with operable windows to facilitate natural ventilation of the building’s interior.

The layered quality of the facade engages the public by absorbing and reflecting the changing conditions of its environment, creating a dynamic tapestry.

• Garden Façade: The lower two floors and all of the south-facing portions of the building feature highly transparent, one-story glass ribbon windows that span floor to ceiling. Every two out of three modules of the unitized aluminum system are fully glazed; the third module is opaque. Operable windows are integrated into every third unit.

• Double-Height Entry Façade: Installed on multi-story spaces at major building entrances. this triple-glazed, steel-framed system produces a very clean interior appearance. Operable flaps at the upper levels of this façade support automated natural ventilation.

• Atrium Façade: The six-story wall of the main atrium is approximately 75 feet wide by 65 feet high, and the three-story wall of the west atrium measures about 45 feet wide by 55 feet high. The challenge—integrating the structural requirements of these long-span glass walls with the exterior sun-shade required to maintain thermal comfort in the atria spaces—is met with a custom shading element that also acts as a rigid wind collector beam. Both the shading system and the triple-glazed wall behind it are suspended from the overhead roof structure.

Behnisch Architekten’s design for the Science and Engineering Complex project pulls together a number of threads of contemporary life, which will certainly influence future generations: engineering’s decisive influence on the discovery and resolution of some of the world's most pressing problems, the critical importance of cross-disciplinary efforts to achieve major research initiatives, and genuine leadership in the area of sustainable design and urban development.