"Industry's Going Upstairs is not only an effective land utilization method but also aligns with the modern requirements of industrial structural upgrading and urban renewal. In the unique national conditions and contemporary context, we aim to achieve spatial model iteration through the typification of factories and the productization of industrial parks. This provides a feasible example for the sustainable development of industrial parks in China."

- Meng Fanhao

Based on a series of practical cases in industrial parks and headquarters office parks, China Energy Conservation and Environmental Protection Group has once again invited Meng Fanhao, co-founder and chief architect of line+ studio, to design its environmental industry park project located in the core area of Fuchun Bay New City in Hangzhou. As a leading enterprise in the field of energy conservation and environmental protection in China, CECEP has developed and constructed more than fifty green parks in the country. The Fuyang Industrial Park will serve as a benchmark for its third-generation standardized parks. Therefore, the owner expects to upgrade the existing flat "industry's going upstairs" factory buildings and create a top-notch green and low-carbon industrial park in China, integrating production, research and development, incubation, and various supporting facilities.

"Industry's going upstairs" refers to a model that deviates from traditional single-story factory buildings. It involves using multi-story and high-rise factory buildings as carriers to vertically distribute the production, office, and other functions of enterprises. This model responds to the demands of urban land scarcity and the requirements of a new industrial structure. In 2021, the National Development and Reform Commission explicitly proposed policies to promote "industry's going upstairs," aiming to create space for the high-quality development of manufacturing and the real economy.

In the design of the Fuyang Industrial Park, line+ innovates and iterates the concept of “industry's going upstairs” through typological research, focusing on both planning and product dimensions. With the mature market experience of the client, we collaboratively developed more market-adapted product types, offering diverse spatial choices within a limited area to enhance land utilization, industrial carrying capacity, and the overall product efficiency of industrial buildings. Simultaneously, we innovated the spatial organization of the industrial park, ensuring efficient production flows while creating a green, sustainable, and community-oriented park environment that seamlessly integrates with the city, resulting in a vibrant and dynamic new industrial park.

01 Land Utilization Rate and Product Diversity vs. Rapid Market Absorption and Maximum Asset Value: Product Development Under High Plot Ratio Constraints

The preconditions given by the planning are “single-floor area not less than 800 square meters, a sales unit not less than 2000 square meters, and a plot ratio of 2.0-2.5.” The market feedback from the owner, however, indicates the highest demand, fastest absorption, and highest premium for single-story buildings of around 3000 square meters. This poses a contradictory proposition. How to create value overflow in the context of high plot ratio and break through the conventional single-story industrial building model? This is a significant challenge we faced at the outset of the design process.

In the early stage of the product type research, we applied the concept of stacked villas from the residential sector to industrial factory projects, proposing the concept of semi-detached factory. We identified a combination model of multi-story standalone factories + “industry's going upstairs” single-story factories + semi-detached factories. These four different product types precisely target different customer groups in the local market, addressing the diverse needs of various enterprises. While meeting the prerequisite of a high plot ratio, we aim to maximize the project's value for the owner, accelerating the pace of project absorption.

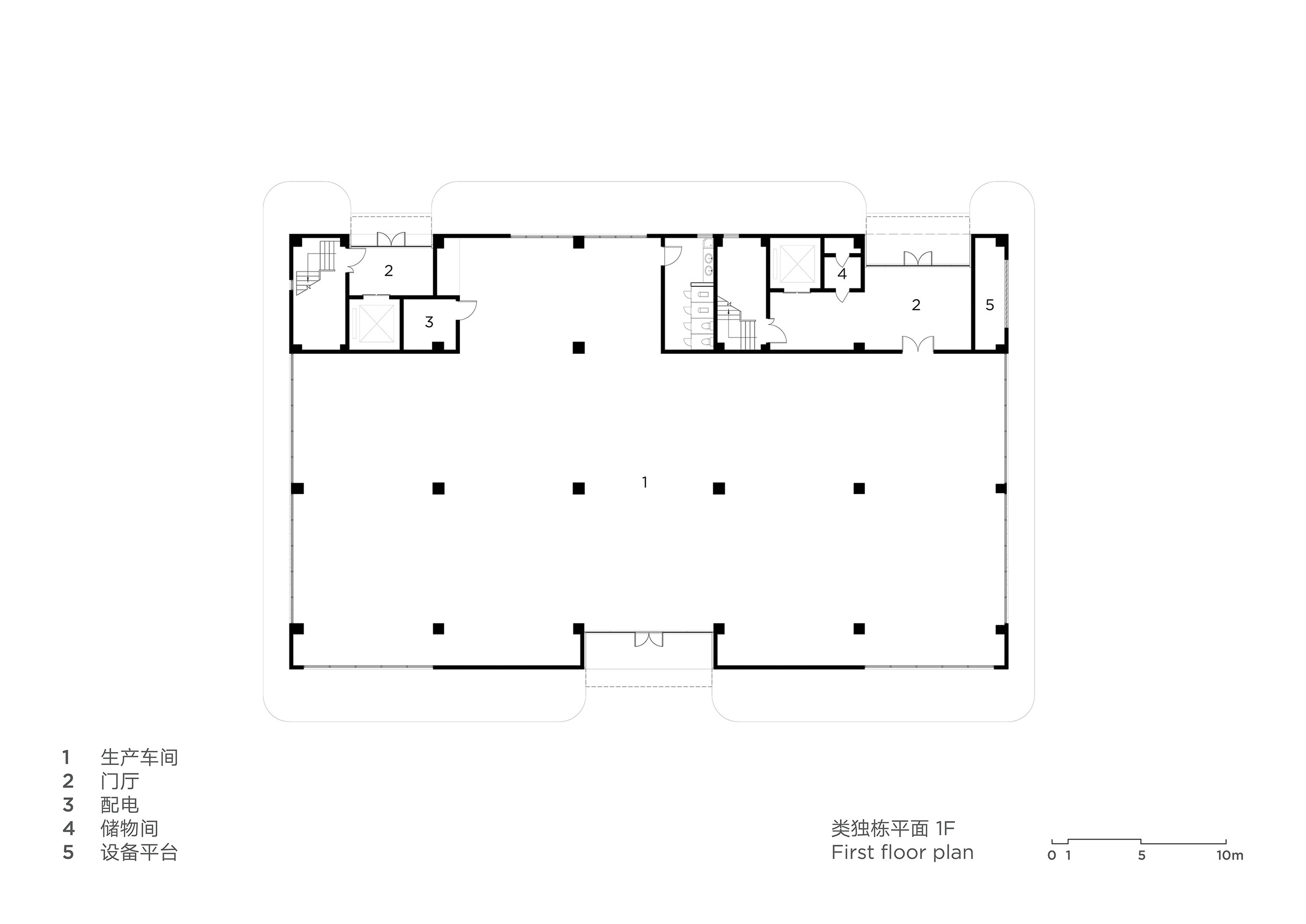

A multi-storey standalone factory, sold by building, with the main structure consisting of four floors, locally ranging from a minimum of three floors to a maximum of five floors. The total area is around 3000 square meters, implementing separate access for customers and goods to facilitate the production needs of heavy machinery being transported upstairs. The internal auxiliary spaces are arranged in a linear and close-fitting layout, making it compact and efficient, with the production space being open and spacious. Additionally, we have designed three sets of interchangeable unit layouts based on different market demands, allowing flexibility for units to be combined or separated as needed.

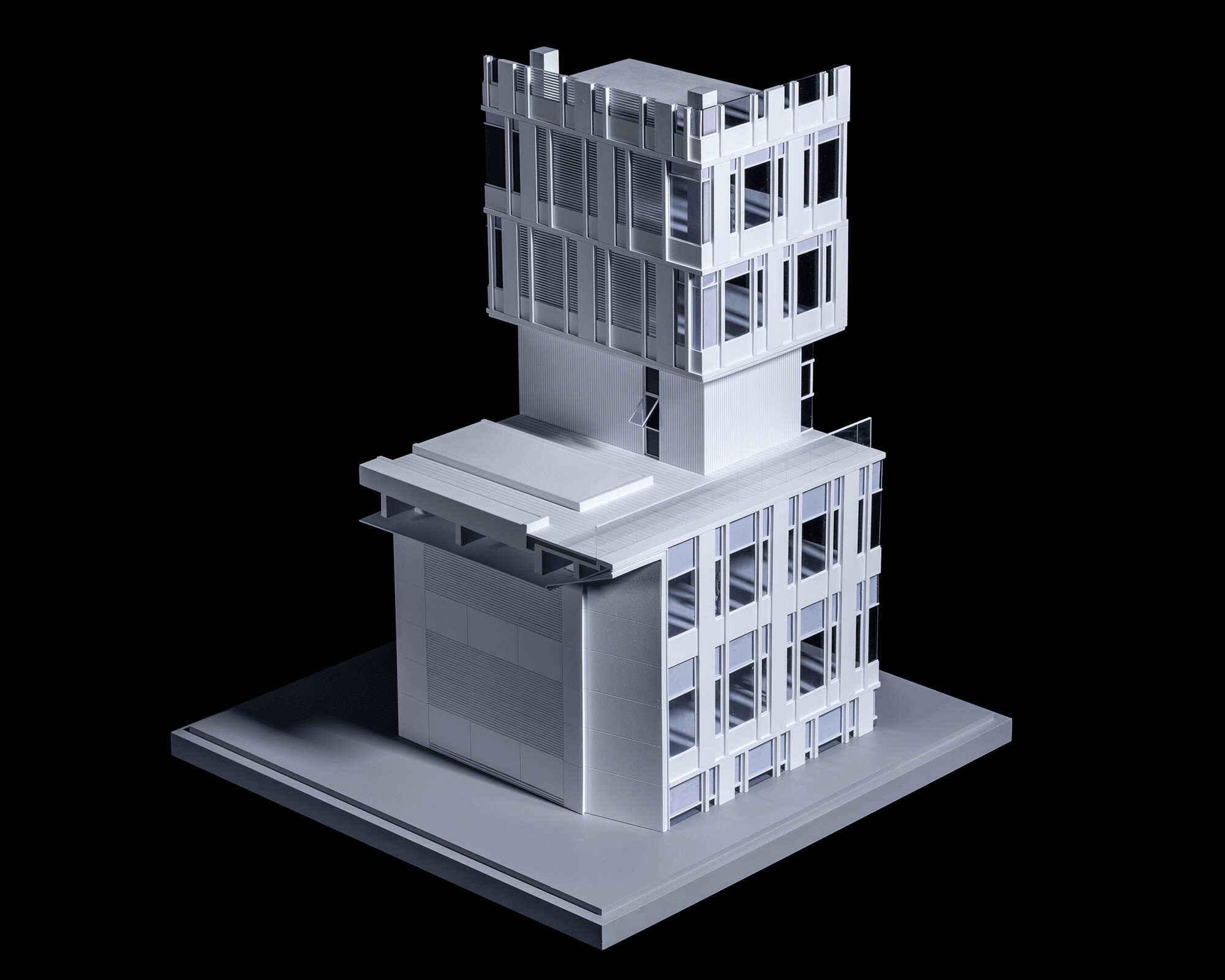

High-rise semi-detached factory buildings are designed with a unique architectural configuration, where the upper three floors and the lower four floors are treated as separate standalone units. Each unit is equipped with independent vertical transportation systems, entrance halls, and courtyards, breaking through the traditional limitations of single-level industrial buildings. This innovative product addresses market demands within the constraints of planning regulations. The lower stack consists of four-floor factory units, with each floor covering an area of approximately 1000 square meters, and they are sold as a single unit with a total area of 4000 square meters. The upper stack comprises three-floor factory units, with each floor covering around 850 square meters, and they are sold as a single unit with a total area of 2500 square meters.

High-rise factories are divided by floors for property ownership, suitable for small-scale enterprises with a horizontal production line layout. The enterprises share the entrance hall and vertical transportation. The lower part consists of single-level flat factories with an area of 2000 square meters per floor, sold as one unit per floor. The upper part consists of single-level stacked factories with an area of 1200 square meters, sold as one unit for every two floors.

In the flat layout design, priority is given to the basic needs of industrial production, with vertical transportation and auxiliary functions arranged in the corners to ensure the integrity of the main space. The column spacing is regular and uniform, facilitating the layout of production lines for enterprises. In terms of plan proportions, considerations are also made for the future versatility as a research and office space, and other functions, avoiding excessive depth.

Thus far, the three types of factory building structures have become gradually clear, responding to various industrial needs through flexible and diverse property ownership arrangements and well-organized floor plans. These designs address different pain points in various industries, generating more diverse value within the constraints of high plot ratios.

02 Efficient Production Flow vs. Strolling in a Park-like Environment: Production-oriented Industrial Parks Guided by Efficient Circulation

The existing site is divided into east and west sections by urban access roads. The east plot has been confirmed for government repurchase and is planned for the construction of high-rise R&D electronic factories. The west plot is primarily focused on cluster-style sales-oriented industrial factories, with spatial requirements considering the versatility for both internal industrial production and research office functions.

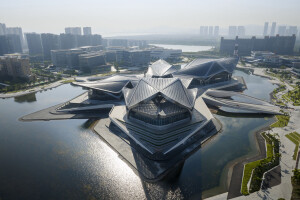

In the overall site design, we prioritize the efficiency and rationality of production flow, ensuring an organized and efficient traffic layout, resulting in a simple and orderly road network. On the other hand, with the fundamental utilization of density, we have organized a central garden by maneuvering individual buildings. Combined with the landscape design of courtyards on the ground floor and the streamlined design for separating customer and goods flow, the overall result is a high-quality park environment.

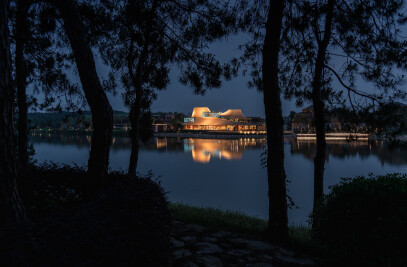

In order to balance the urban image, we have positioned the two tallest towers, each standing at 60 meters, on the far north side of the west plot, facing the main urban thoroughfare. This arrangement also aligns with the sunlight conditions, with a lower height to the south and a higher height to the north. On the southern side of the site, facing the high-speed rail, we have elevated the buildings on the southwestern side of the site, implementing a distinctive architectural treatment. This approach creates an overall image where high and low buildings interlock, and the architectural language maintains a clear hierarchy.

To achieve a 2.0 plot ratio, four seven-story semi-detached factory buildings, each 31 meters in height, are sequentially arranged along the secondary road on the west side. This arrangement creates a continuous interface facing outward and a high-quality park environment internally. Additionally, ten multi-story standalone factory buildings are strategically positioned."

03 Standard Construction vs. Individual Showcase: Ultimate Quality Control within Conventional Costs\

With the rapid development of production-oriented industrial parks following the trends of a younger workforce and diversified functional integration, differentiated and personalized architectural environments are gradually becoming the core competitive strengths of clustered parks.

With cost constraints in mind, we have opted for innovative applications of conventional materials such as soft ceramics, coatings, aluminum panels, glass, etc. Our aim is to find a balance between cost and spatial quality through the innovative use of standard materials. By refining and differentiating the facade's color and texture, we aim to provide industrial buildings with opportunities for personalized showcases.

The high-rise and multi-story buildings located at the periphery of the site adopt a facade language of homogeneous window panels, creating a unified and distinct overall image. The use of homogeneous window panels also ensures uniform indoor lighting, meeting the most basic functional requirements of industrial production for space.

To prevent damage to the glass during the production process, such as the transportation of equipment and materials, we have abandoned the practice of using floor-to-ceiling glass from the previous generation industrial park. Instead, we have set a 900mm high windowsill under the windows, which not only saves costs but also meets practical production needs. Additionally, as a design element of the facade, the recessed windowsill is painted with orange textured paint to enhance the facade's sense of depth.

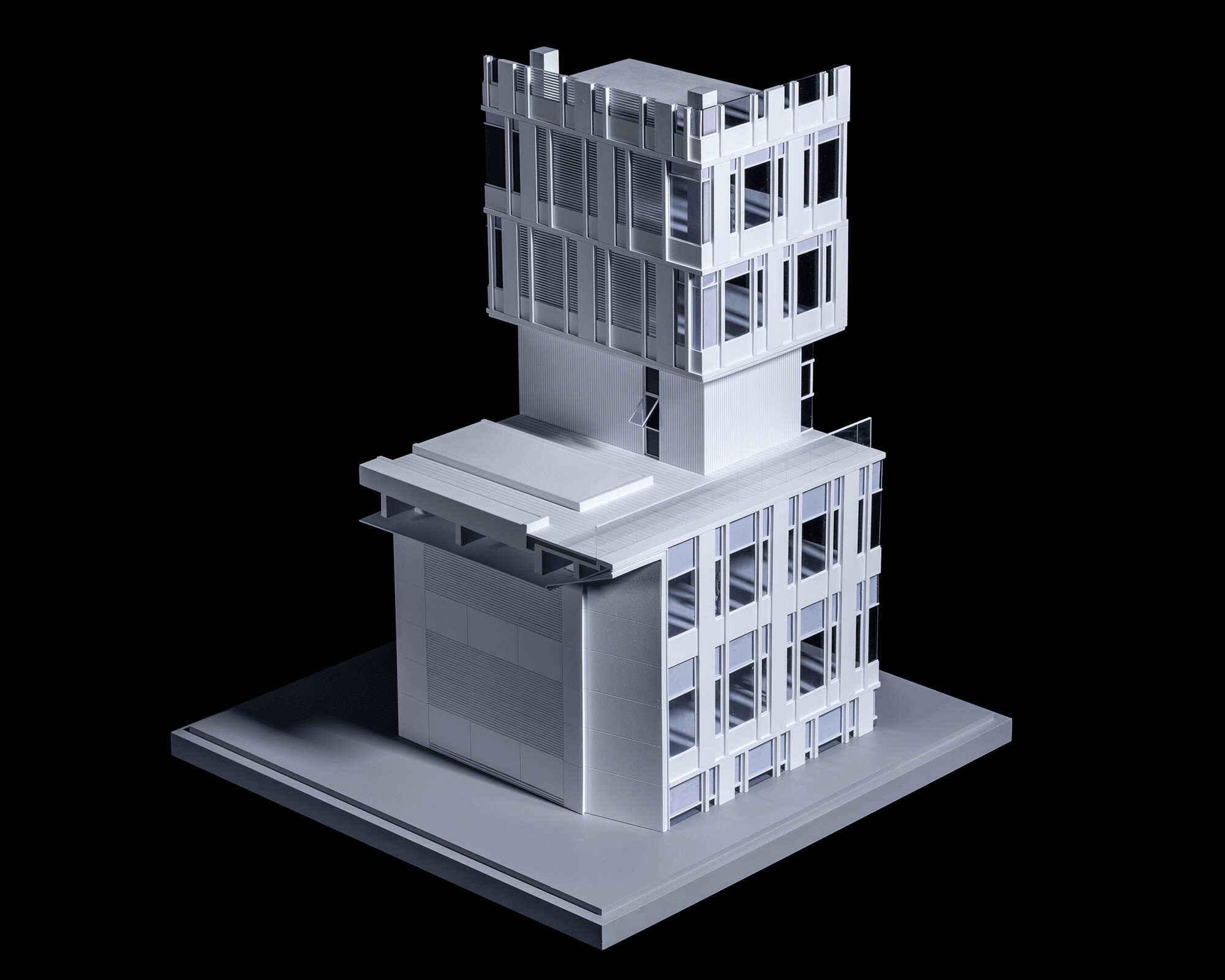

Multi-story standalone factory buildings are commonly used for the three-in-one combination of small enterprise headquarters, research and development offices, and production operations. By creating a staggered form, terraces are formed, and internally, corresponding auxiliary functions such as equipment platforms, storage rooms, and tea rooms are accommodated to achieve efficient stacking of functional spaces.

In the facade design, the lower volume is clad in deep gray bamboo-joint bricks arranged in a horizontal staggered pattern. The upper volume is clad in soft ceramics primarily made of Modified Clay Material (MCM), a new type of energy-efficient and low-carbon building material with good flexibility and texture. Cut into strips of 200*1200mm dimensions, three colors are mixed and matched to create a differentiated architectural expression.

The construction of the wall has undergone careful consideration in terms of form and materials. Following the vertical movement of the building form and the division of different materials, we have designed 200*200mm grooves to serve as transitions between the deep gray bamboo-joint bricks and the colored soft ceramics. The upper and lower ends of the grooves are closed with metal plates for the two materials, enhancing the dynamic movement of the architectural form while ensuring a logical junction between different materials in the construction.

The semi-detached factory building, as a new product positioned between multi-story standalone factories and high-rise single-level factories, is designed with a focus on property ownership division. Taking into account the different property ownerships for the upper and lower parts, we use a stacking approach with two volumes to achieve a logical unity in form and ownership division.

To ensure the uniformity of the street-facing facade in the park, the upper stack adopts the construction method of homogeneous vertically staggered windows, while the lower stack volume responds with horizontal band-shaped windows. The lower stack employs prefabricated concrete blocks to create a lattice pattern with staggered treatment, presenting a contrasting yet unified look. The inter-floor spaces are resolved through civil engineering to form 200*200mm grooves, alleviating the heaviness of the lower volume. These grooves are coated with dark green paint, adding a lively element to the subdued concrete texture.

04 Remark

Recently, the results of the evaluation for the 15th batch of the "Green Building Certification" project in 2022, organized by the China Urban Science Research Association, have been announced. The project has been awarded the one-star Green Building Certification, the only one in the industrial construction category.

The upgrading of industries necessitates constant iteration of spatial models. Against the backdrop of the widespread implementation of "Industry's Going Upstairs," line+ leveraged its advantages in product development. Focusing on strategic emerging industries such as energy conservation, environmental protection, intelligent manufacturing, and electronic information technology, we broke away from the traditional single-mode spatial design of factories. We customized a series of high-rise, standalone, and semi-detached spatial types, creating a diversified combination to build a high-quality industrial park. This enhances land efficiency, development intensity, and empowers the iterative evolution of industrial parks.

Project Name: CECEP (Fuyang) Environmental Protection Industry Park

Design Firm: line+ studio、gad

Chief Architect/Project Principal: Meng Fanhao

Project Architect: Li Xinguang

Design Team: Yuan Dong, Hao Jun, Tu Dan, Zhang Tao, Xing Shu

Owner: CECEP (Hangzhou) Environmental Industry Co., Ltd.

Construction Drawing Collaboration: Hangzhou Urban Construction Design & Research Institute Co., Ltd.

Project Location: Zhejiang, Hangzhou

Building Area: 163,168.18 square meters

Floor Area Ratio: 2.1

Design Period: 2020/07-2021/03

Construction Period: 2021/04-2023/07

Structure: Frame Structure

Materials: Textured Paint, Imitation Concrete Coating, Soft Ceramics, Aluminum Panels, Glass

Photography: Chen Xi Studio, line+