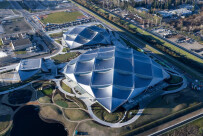

International firm BIG - Bjarke Ingels Group and London-based Heatherwick Studio have completed a triplet of lightweight, long-span structures for the technology company Google. The buildings feature concave roofs clad in 50,000 photovoltaic panels - a ‘solar skin’ that absorbs the California sun and transforms its energy into electrical power for the new campus supporting thousands of users.

Silicon Valley became a wellspring of groundbreaking products decades before its companies ventured into the business of realizing innovative architecture.

It wasn’t until Google's first campus headquarters - the Googleplex, opened in 2004 and designed by Clive Wilkinson Architects - that the region’s tech industry began setting architectural design standards with inventive open space planning and dynamic programming. More recently, Foster + Partners’ ring-shaped headquarters for Apple in Cupertino and Gehry Partners’ Menlo Park headquarters for Facebook, opened in 2017 and 2018, respectively, made headlines for their sheer scale. The former is notable for its pure geometry and clean aesthetic, and the latter for its playful, informal design.

And now the epicenter of tech has a new architectural landmark: Google’s Bay View campus. The project features a set of long-span lightweight structures that yield double-curved envelopes finished with a system of ‘solar shingles’. The campus’s immense use of photo voltaics, a technology which uses silicon as a semiconductor, can even be said to have expanded Silicon Valley’s association with the material beyond its historical use in computer hardware. The three buildings that comprise Google’s new headquarters feature surfaces of photovoltaics large enough to generate the equivalent amount of energy needed to power 3500 single family homes over one year. Google estimates that this photovoltaic skin will supply some 40 percent of the campus energy needs.

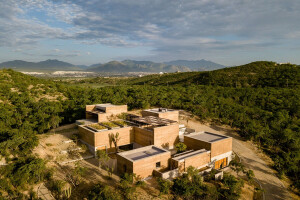

The campus houses 1.1 million square feet (102,000 square meters) of space. It includes two workspace buildings, a 1,000-person event center and 240 short-term employee accommodation units. The structures sit on a site of 42 acres boasting restored wetlands, woodlands and marshlands. The project is the largest structure to achieve LEED Platinum certification while also becoming the biggest facility to achieve the International Living Future Institute LBC Water Petal Certification, which recognises wastewater and storm water reuse.

While amidst a period of rapid growth, Google’s founders sought to plan a new campus that could serve the future. The company was in need of new flexible space, and lots of it. Google’s planning team approached the architects with a brief to design a campus for thousands of desks that could evolve with the company. “They wanted a building that could stand the test of time,” says Blake Smith, an Associate at BIG and Project Designer for Bay View.

According to Smith, the project developed as a direct relationship between the architects and Google's leadership. Larry Page in particular was crucial to the earliest stages of design.“He asked us to deliver a moonshot request,” says Smith. “He wanted a structure with a perfect enclosure: one that was weightless, invisible, energy-generating, supporting biophilia, providing optimum indoor air quality and ideal lighting conditions for computer and desk work.”

As part of the design team’s initial tour of the site, it visited the adjacent Moffett Federal Airfield, home to hangars built to serve the American air force during both World Wars. “We were struck by the scale and integrity of the structures, the unique context they created, and especially their versatility for a life well beyond their original use,” according to Smith. The lightweight flexible forms and expansive spaces persuaded the architects that Google’s ambitions might be met with a sort of modern hangar. “The idea of a minimal canopy hovering above villages of teams, emerged as a means to provide flexibility while creating an activated, campus-like experience.”

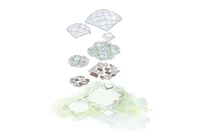

The BIG and Heatherwick team focused on long-span structures as the launching point for the project. In its conceptual studies the design team exhausted the canon of structural typologies. “We explored the gamut,” says Smith. Domes, shells, space frames, glass tensile fabrics with integrated photovoltaics and even a fully inflatable pneumatic structure were all studied for how they might provide an adequate enclosure for thousands of Googlers. The final design is a hybrid of long-span typologies, combining compressive and tensile forms.

To determine the nature and form of the structure, the architects started with the needs of a Googler, how they collaborate, the nature of teams and their proclivity for growth. The design team underwent an extensive process of feedback and outreach with Google, meeting people across all departments, from data security employees to programmers.

According to Smith, “Google provides a vast amount of amenities and assets to their employees,” through fitness centers, massage rooms, doctor's offices, cafes and coffee shops. “These are much loved and they make Google an incredible place to work. But what we heard from the programmers is that it can also be distracting to have all of this buzz of activity in the workplace. People are constantly moving to and from these amenities, and the spaces can get noisy.” This led BIG to consider a two-floor arrangement, where office spaces are set above common spaces that include conference rooms and amenities. Smith describes the second floor as a “cathedral for focusing.”

The structures taper to a peak, so they are tall in the center, yet unimposing at the edges where one enters. “The scale of the interior volume and repetitive nature of the structure evoke a sense of the sublime,” says Smith. The design allows for a sense of community among a population of Googlers that reaches into the thousands, while the interior architecture was modeled to maintain intimacy and foster collaboration among smaller groups of people. To enhance the future flexibility of the campus, the interior structure is completely detached from the canopy. It can be removed or replaced as needs change.

“Urbanistically, we wanted the buildings to feel elegant and light, despite being massive,” says Smith. From the outside, the campus is experienced as a series of low-slung canopies that touch the ground gently in four corners.

The roof’s geometry addresses thermal comfort and acoustics. As in other large structures, such as airport terminals, the interior volume is expansive enough that it stratifies heat and therefore passively yields displacement ventilation. Its canopy overhangs project shadows onto the glass facades, while an automated shade system provides additional comfort and protection from glare. An extensive geothermal system installed in structural piles - the largest such install in North America - further allows the building to provide thermal comfort year-round. The design team estimates that, as a result, carbon emissions are reduced by 50 percent and water used for cooling by 90 percent.

The convex interior geometry of the bays assists with acoustics by reflecting sounds in various directions about the spaces rather than concentrating them, avoiding the sort of echoing conditions one might experience in a domed or vaulted space. Lower portions of the canopy are built with perforated metal containing acoustic absorption panels. At the second floor, carpet and flexible partitions are used to improve privacy and local acoustics.

Drainage and Maintenance

The canopies were designed to maximize the collection of rainwater. Each bay has a high point and low point, located at the corners, which allow for positive drainage without the use of pumps. Downspouts are housed within columns and at the canopy perimeter, and rainwater is collected in a series of surface ponds. The water is treated onsite, combined with treated wastewater and re-used to meet all non-potable demands of the campus.

Catwalks and doors along and within the clerestories are accessed from canopy columns for roof maintenance. Additional maintenance walkways and tie-off points ensure safe access along the perimeter of the sloping bays. The glass-topped photovoltaic panels support human weight and can be walked on directly.

“Our driving goal for the roof was to create a beautiful, lightweight structure that balances the need to generate energy with the desire for natural light,” says Smith. The largely opaque canopies maximize surface area for harvesting the sun’s energy, while clerestory windows invite indirect natural light that allows views to the sky yet limits glare on computer screens.

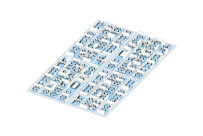

Square tensile bays span 123 feet (37 meters) and are supported on slender cruciform columns that transfer loads as well as house electrical conduits serving the photovoltaics and the rainwater pipes that run from the canopy down to the ground.

Each bay consists of a grid of steel tubes that are stitched together by Vierendeel trusses on all sides, functioning as a sort of structural net. Perforated steel decking with acoustic absorption between the flutes is installed above, topped with a waterproofing layer and halters to support the metal standing seam for drainage.

Unistrut is attached to the metal seams and serves as a rail system for the photovoltaic system of solar shingles. This detail allows for differentiation between the standing seam direction and shingle orientation, helping to achieve the ‘dragon-scale’ texture. Stainless steel coping provides visually crisp edges at each canopy bay.

Photovoltaics, for all their benefits, are more often than not unsightly additions to architectural projects. But the product used for the Google Bay View campus has a unique form, texture and color that is refined and well-integrated, like the scales of a fish that appear to change with orientation, making for a surface that is rather unrecognizable as a photovoltaic system.

50,000 photovoltaics measuring 3 x 3 feet (1 x 1 meter) were produced for the project by the Swiss company SunStyle. The term ‘shingle’ is apt in that the product is used as cladding and can take the shape of surfaces both flat and curved. The form of the product, according to SunStyle, was inspired by the slate roofs of the Swiss Alpine region.

The shingles are composite panels consisting of laminated photovoltaic cells topped with a layer of prismatic tempered and textured glass that has multiple benefits: it reduces glare on the roof, provides a complex finish that obscures the color and appearance of the cells, and also helps to recapture some of the photons that would otherwise be reflected from cells.

According to SunStyle’s product specification, the panel is a monocrystalline solar cell type, meaning it makes use of single pieces of silicone as a semiconductor, as opposed to polycrystalline cells which are less efficient. The SunStyle panels are of type Passivated Emitter and Rear Contact (PERC) which include an extra silicon layer to reflect some of the sun’s rays back into the cell, allowing them to produce more energy than conventional solar panels.

Each shingle has a nominal output of 110 wp (watt peak) and an efficiency of 17 percent. The system is a patented roofing solution that is watertight through its overlapping application, durable and warrantied for 25 years. The product is manufactured with smooth or textured glass and optional color-coating.