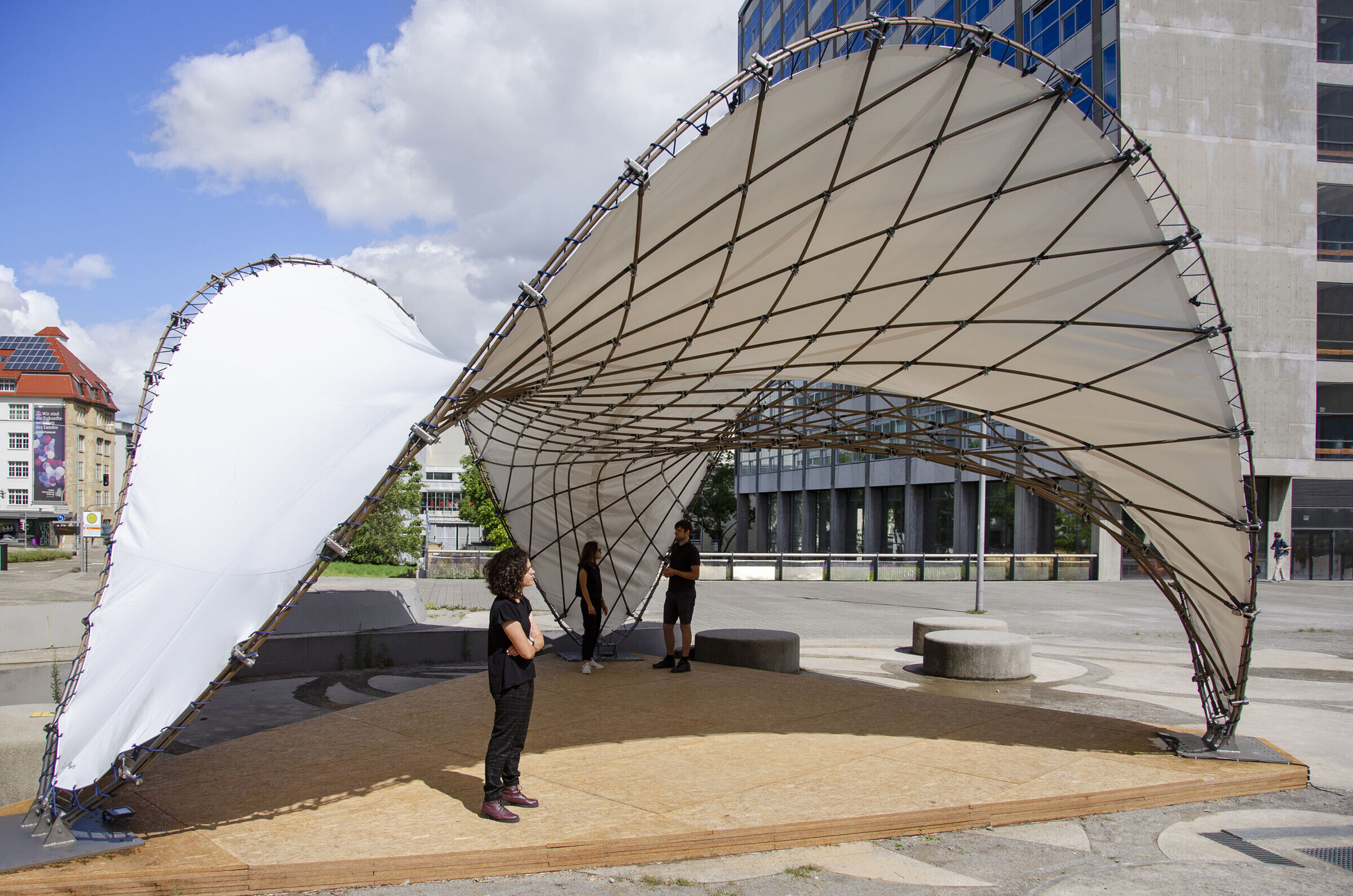

The LightPRO Shell (BioMat Pavilion 2021) is a lightweight structure that combines an active-bending gridshell made of natural fibre biocomposite profiles with a tensile membrane. The resulting system is a combination of two doubly curved surfaces that share a continuous beam outline.

The developed ‘bamboo-like’ natural fibre-based biocomposite profiles are newly produced through the pultrusion technique. Pultrusion is a continuous process for manufacturing fibre reinforced polymers with a constant cross section. In this project, natural flax and hemp fibres were used. The produced profiles are hollow, with a diameter of 25mm and 4mm thickness and lengths ranging from 6.5m to 12.5m to fit the required span.

To show the material's capabilities, a number of experiments were carried out. Multiple samples were produced while the recipe was being evaluated. The goal was to create a product that matched the mechanical qualities of bamboo and other related materials. The material's capacity to bend was emphasized. Profiles of 12,5m length, for instance, were able to achieve a radius of 5,25m and a deformation of 4,9m. Additional in-house tests were conducted to see if the profiles could attain double curvature.

The developed profiles are used as load-bearing elements in an active-bending structure. Active-bending structures are systems where initially straight elements are being bent to form a curved shell. As a result, the profiles' flexibility was critical. A number of design possibilities were considered. The selected design was chosen based on its distinctive shape, as well as the emphasis it places on the curved structural components. The most distinguishing feature of this design is the continuous beam outline. This was also an additional challenge, as the material had to be sufficient to support the entire geometry. The pavilion consists of 44 profiles with lengths varying from 6 to 12.5 m. It has a covering span of 10m and maximum height of 4.8m at the perimeter.

Integration of a skin was of great importance in this study. The addition of a polyester membrane was decided. The skin itself acts as a second system. Thus, the final structure consists of two structural systems, both of which form doubly curved geometries: a lightweight gridshell of biocomposite profiles and a tensile membrane shell. The two geometries are distanced from each other and only connected through a shared beam-outline. To support both, the outline is composed of two connected profiles that act as a beam, transferring forces from both systems to three anchor points attached to a superficial foundation.

Traditional diagonal lashing methods with steel cables are used to join the profiles in a grid. The grid is connected to the beam outline via a customized joint system. The membrane is attached to the three foundations and tensioned along the perimeter using rope lacing.

This innovative structure is demonstrating a sustainability approach towards future architecture. The outcome is based on several years of research in the field of biobased materials application.

Material development and production was carried out by the partners from DITF, CG-TEC and BAM. Zenvision GmbH was involved in the technical design and development phases. Steinhuder assisted in assessing an alternative bio-based connection system of the structure. Bieri produced and sponsored the membrane.

The pavilion is a result of intensive work linked to the research project LeichtPRO and is financed by FNR (Federal Agency of Renewable Resources)/ BMEL (Federal Ministry of Food and Agriculture), FKZ: 22027018.

Team:

BioMat/itke, University of Stuttgart

Pavilion Team:

BioMat Director: Jun.-Prof. Dr.-Ing. M.Eng. Hanaa Dahy

BioMat Team: Evgenia Spyridonos | Dr. Jan Petrš | Piotr Baszyński | Paulina Grabowska

Structural Support: Yanan Guo | Marta Gil Pérez

Geodesy Team: Prof. Dr.-Ing. Volker Schwieger | Gabriel Kerekes

Membrane Support: Bieri GmbH | Technical: Tomas Thommen

Membrane Assembly: Zimmermann Zeltbauten | Technical: Ronald Burgau

Technical support: Michael Preisack | Michael Schneider | Michael Tondera

IntCDC Laboratory: Sergej Klassen| Kai Stiefenhofer

LeichtPRO Project Partners:

Zenvision GmbH: Carsten Fulland | Jacob Börner

DITF: Prof. Dr.-Ing. Markus Milwich | Martin-Uwe Witt | Dr. Mark Steinmann | Patrick Kaiser | Marion Gebhardt

CG-TEC: Andreas Gerstner| Oliver Kipf | Manuel Rupp | Michael Nehmeier

BAM: Dr. Klaus Dippon | Uwe Schönfeld

Steinhuder: Michael Wölfl

Participating students:

Winter Semester 2020/21 (concept stage): Dominik Abele | Alexander Jansen | Sarah Rüngeler | Viktoria Schüle| Daniela Solueva | Rita Teixeira | Louisa Teufel | Ekin Şiar Baloğlu

Summer Semester 2021 (development, fabrication, building phase): Matay Kaplan | Fabian Schmid | Vural M. Ali | Larisa Elena Simion | Maysa Abu Alqumboz | Sarah Rüngeler| Dominik Abele| Anastasia Kandylaki

Student assistants: Rita Teixeira | Daniela Solueva | Mahnaz Shahriyari | David Schadwill

Special Thanks to: Asmaa Hassan

Material Used :

1. Main structural elements: Natural fibre pultruded profiles developed in LeichtPRO research project, produced by company CG TEC

2. Skin: Membrane, produced by Bieri company

3. Connections/foundations: Steel and timber elements