History

Innovative wood materials for over 85 years

In the year 1923, Jakob Friedrich Werz founds a small animal glue factory in Göppingen to supply local craftsmen and plywood manufacturers.

In 1941, he takes over the company of a former glue customer in Oberstenfeld, Ludwigsburg district, that produced moulded plywood (chair seats and backs, plywood housings for the German radio and phonograph industry, etc.).

Starting in the mid-1950s, a completely new process is developed, subsequently patented as the WERZALIT process, in which finely chipped wood is mixed with synthetic resin glue and additives to produce ready-to-use table surfaces, serving trays, wall panelling and similar parts - the origin of the WERZALIT wood material.

WERZALIT gradually becomes the name of the material, the name of the process and even the name of the company. Numerous patents are also acquired to secure the production know-how of the WERZALIT process. Over time, the process is also licensed both in Germany and abroad.

Due to health problems on the part of the company owner, Jakob Frieder Werz, the company has to be sold in the year 1987 to an Austrian company with an international character.

Back under family ownership since 2002, WERZALIT is now led by General Manager Jochen Werz, a grandson of the company founder. Mr. Werz views the actual history of WERZALIT as a challenge to constantly strive for something new with a commitment to innovation. "Innovation is a basic value for me. We want to increasingly develop products and enter into new technologies." In this spirit and under the management of Jochen Werz, the company developed a completely new wood and polymer material called "S2", a type of wood-plastic composite (WPC).

Sustainability

PEFC wood for sustainable products

The most important raw material for products of WERZALIT is wood. In Germany, industrial wood originating from forests in a narrow radius of less than 100 kilometres is used. The environmental managers at the company ensure that the wood suppliers are exclusively PEFC-certified forestry operations.

International and independent

PEFC stands for Programme for the Endorsement of Forest Certification Schemes, an independent, non-profit NGO. The organisation works around the world, evaluating and pursuing mutual recognition of national forest certification schemes.

Economic, environmental and social standards

The forest certification can only be successful if the wood with the PEFC certificate makes it to end consumers. This requires certification of even the wood-processing companies in the product chain. For years, WERZALIT has worked together with such certified forestry operations. The primary goal of PEFC is documenting and improving sustainable forest management with regard to economic, environmental and social standards.

Assurance of responsible behaviour

The PEFC certificate offers buyers of wood products the assurance that the manufacturers are promoting sustainable forest management through their actions. It certifies WERZALIT as a responsible and environmentally friendly manufacturer.

Materials

The most beautiful combinations of wood

WERZALIT makes use of modern materials that exhibit extremely advantageous properties ranging from durability to environmental friendliness.

Made for a long life

WERZALIT materials pass extreme endurance tests during continuous production, such as swell tests and paint flaking tests. In special climate chambers, the material is subjected to a range of environmental factors and temperature fluctuations between -20 and +70 °C. For instance, test façades in the WERZALIT testing fields have outlasted wind and weather for 30 years. WERZALIT façade profiles are even tested for earthquake safety.

WERZALIT wood material

The proven WERZALIT wood material is used in our balcony and façade profiles, window sills and table tops. The patented manufacturing process combines the natural properties of wood with the resistance of high-quality resins. The coating is indelibly fused with the highly compressed wood material.

S2 wood-polymer composite (WPC)

Terrace products are made of the S2 wood-polymer composite (WPC). With S2, WERZALIT has developed a material that combines the advantages of wood and plastic. It can be worked as easily as wood but has the moulding and flowing properties of a thermoplastic. Extrusion and injection moulding techniques, previously reserved only for plastics, are now also available for wood in the form of S2. S2 has an unmistakeable fibre structure of dyed polymer and wood fibres.

Laminated panels

WERZALIT balcony cladding panels are made of multiple cellulose sheets impregnated with resin and pressed into a homogeneous panel. The core sheets lend the panels the durability to withstand further processing. The decor paper is saturated with melamine resin, one of the hardest resins available, and the transparent overlay forms a nearly indestructible surface. The structure of the panel is designed perfectly for use as façade or balcony cladding.

Werzalit Product

terraza Kassette Werzalit

terraza terrace tile.

Square. Practical

The square terraza terrace tiles offer an

attractive alternative to profiles – especially

as fl ooring on...

Other Facades Products

Member Promotion

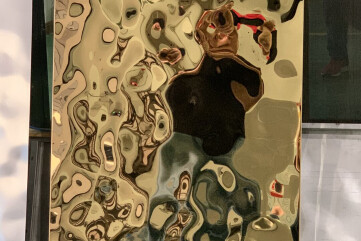

Blue mirrored water ripple sheets Wuxi Boweite Metal Co.,Ltd

The water ripple stainlss steel sheets has been popular invarious decorative industries for a long time, with acid resistance, alkali resistance, high...

Water ripple C002 Wuxi Boweite Metal Co.,Ltd

Material: stainless steel 304, 316,316L ,etc

Thickness:0.6~3.0mm

Width: 1000mm, 1220mm, 1250mm,1500MM

Length: max 5000mm

Surface: No.8 mir...

Werzalit Offices

Facades Brands

Is this your brand and would you like to remove content from other manufacturers on your brand page? Contact Archello