First of five buildings planned for the ECR complex in Sopot, Poland

"Those who live by the sea can hardly form a single thought of which the sea would not be part.” ― Hermann Broch

Wave One, of the European Center for Families, is located 400 meters from the Baltic Sea in what is historically known as a health resort town. The concept is derived from the complexity of sea waves and the local vernacular of carved ornamental detailing on facade elements. Drawing upon this, the architects created a site concept composed of five inter-related buildings, reminiscent of waves. Wave One, the first to be built after a lengthy design and construction process, encompasses specialized medical laboratories, including SARS-CoV-2 testing labs, a research & development center, and administration spaces.

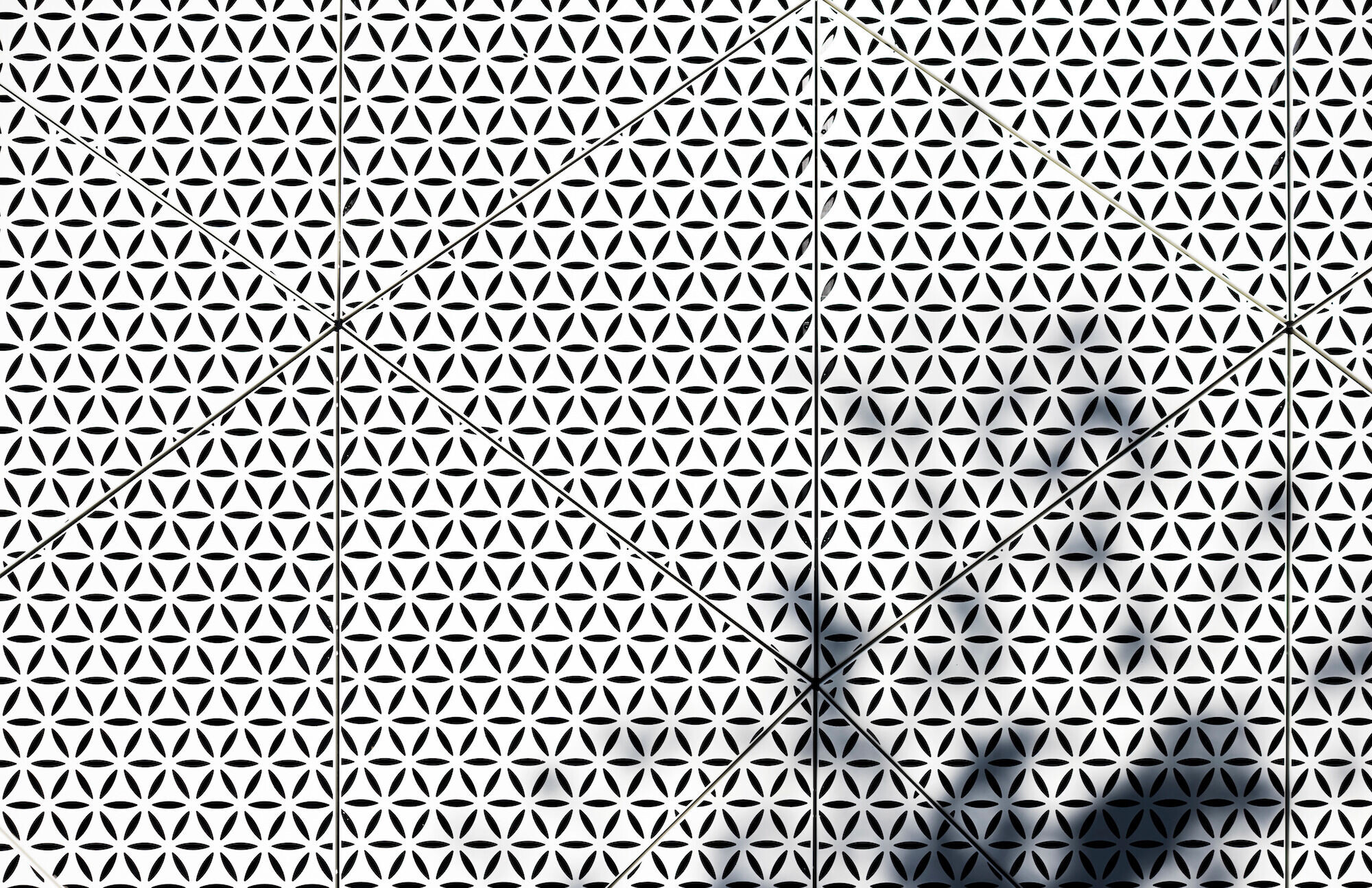

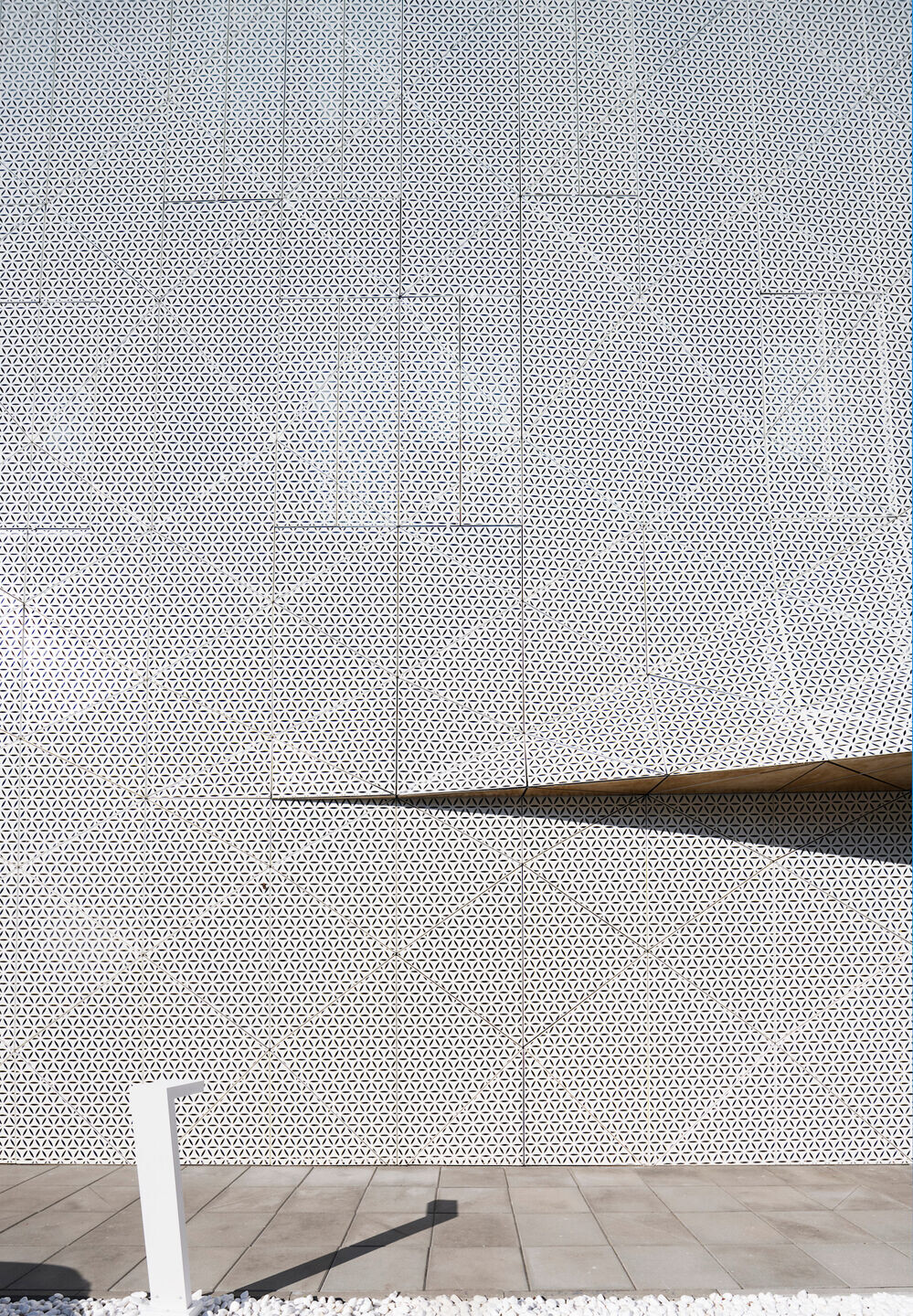

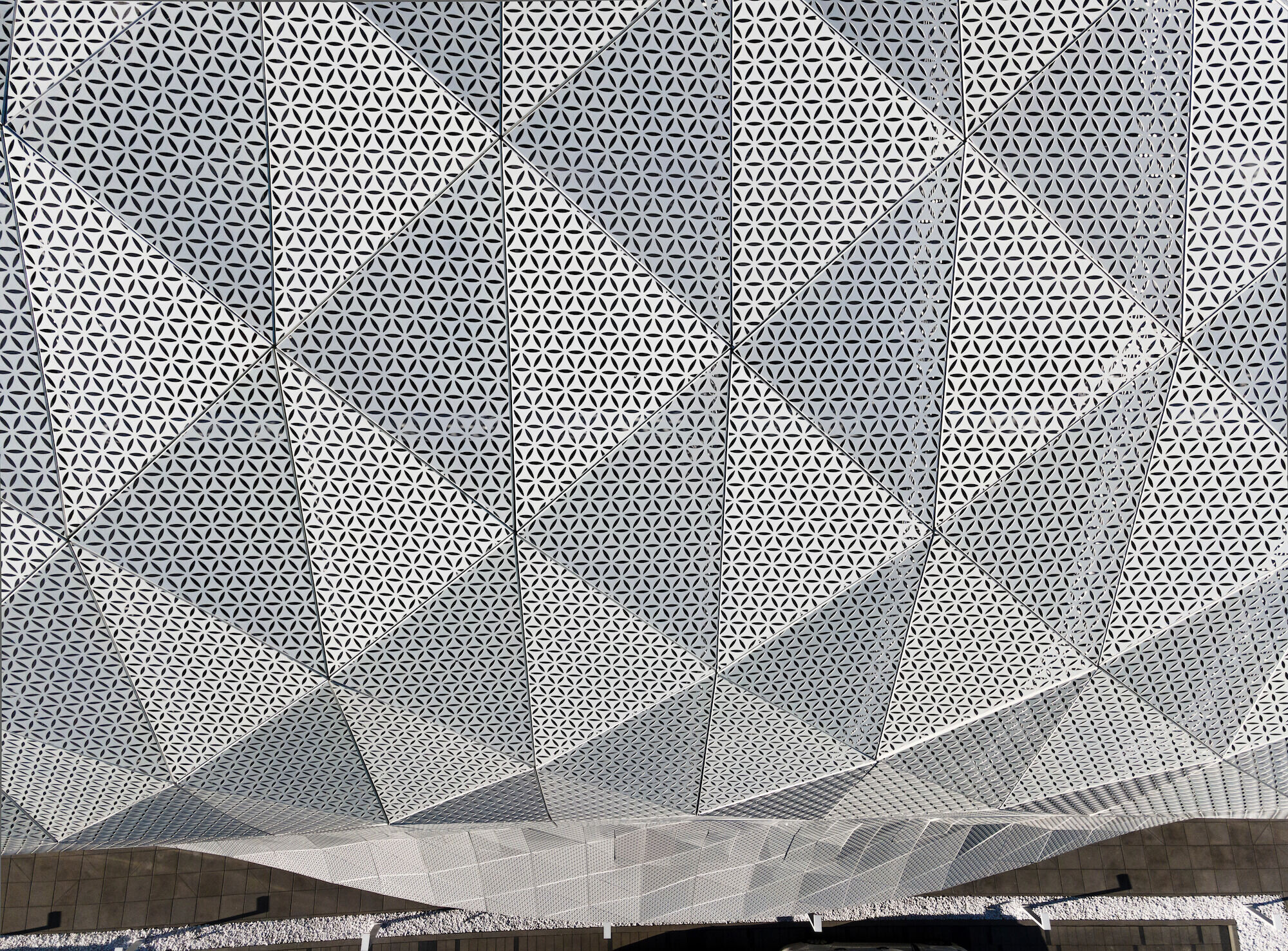

The white perforated facade, enfolding Wave One, was partly inspired by a series of photographs by Pierre Carreau, titled AquaViva. The architects analyzed the geometric complexity of the sea waves captured by the photographer. The arched 3D forms, frozen in time, were translated into an architectural language that shaped the building’s final form. With 1,362 perforated triangular panels, the facade, just like a wave, bends at its crest, the top of the building.

The perforated panels are a symbolic gesture referencing:

1) the local tradition of placing ornamental details carved in wood on building facades, and

2) flower of life, an ancient motif credited with healing powers, befitting the healthcare function of the investment.

The perforations made it possible to elicit an airiness and dissipation of the building in space, particularly visible in the upper realm of the facade.

The East/West elevations take on 3D form, with triangular panels of sintered white ceramics skewing and reflecting sunlight onto the pavement. They create a transient detail, enlivening the immediate surroundings of the building.

Equally, curvature - a reference to the concavity of a sea wave - inspired the shape of the building mass. The amply curved canopy over the South entrance was digitally 3D modelled by the architects, and was then submitted to the local contractors for the preparation of one-to-one mock-ups. Adjustments were made on-site in order to create a seamless union with adjacent panels, and to ensure the fluidity of the perforated pattern. This was a painstaking task, given that curvature and deviation from the vertical are along both axes of the facade, not excluding the additional presence of operable shutters.

Function per floor

Below ground: cold and reagent stores, server, and technical rooms.

Ground floor: lobby, collection point, medical analytical laboratory with fully automated medical laboratory equipment based on robotic sorting lines.

First floor: molecular biology laboratory carrying out research in the field of genetics. Cytology, cytogenetics, and virological laboratory is adjacent.

Second floor: research and development center. This center also creates specialized software to streamline implementation and increase accessibility of medical procedures. The software is based on artificial intelligence and machine learning technologies.

Third floor: Investor headquarters and offices intended for the development of research projects.

Terrace: divided into technical and recreational spaces by an acoustically insulating wall. The recreational terrace is available to all employees and provides work place well-being and a visual connection to the Baltic Sea.

Due to the difficult situation in 2020 (availability of testing facilities), a decision was made during construction to convert part of the space into a SARS-CoV-2 diagnostics lab. This laboratory continues to be used to determine new types of mutations. A vaccination point was organized in the building and is used by the inhabitants of Sopot.

Impact

The ecological solutions selected for the project result directly from local conditions and respond to the actual demand determined by the function of the building. Due to the difficult construction conditions of Lower Sopot, including flooding, high groundwater levels, and the presence of non-bearing soil, the site remained undeveloped for years.

Heat management

In a facility with such a high saturation of technological equipment, many of which have to work 24 hours a day, it is very important to protect the rooms from overheating. Overly high temperatures inside the building not only cause discomfort, but can also trigger a sudden shutdown of laboratory equipment. This, in turn, usually leads to the discontinuity of the analysis cycle, as well as the loss of the precious research material.

In order to avoid such threats, and to prevent enlarging the cooling systems, a number of passive solutions were used. For instance, the architects resigned from large glass surfaces. Instead, the surface area of the designed windows provides optimal natural lighting conditions for the laboratory rooms. The largest room, in which the technological line generating the greatest amount of heat was placed, is located on the North side.

Furthermore, the building façade consists of two layers. The outer layer of the facade acts as a continuous protective barrier over the building, shielding the exterior wall from heating up, and thus preventing the interior rooms from overheating. This barrier also has a positive effect on its surroundings and guards against urban heat island phenomenon.

Rain water management

Several solutions to rainwater management were introduced. An extensive rainwater retention system and buffer tank were installed. The water collection from the tank is used to flush the toilets, thereby limiting the use of water from the municipal network. Additionally, to avert rainwater contamination, external wooden elements were used that do not require chemical treatments.

Adaptation

The interiors, in particular the lab rooms, were designed to adapt to the frequent technological advances in medical diagnostic services that will inevitably be introduced in the future. As such, rooms where laboratory tests are performed inside closed automated lab devices have exposed ceiling installations. Partition walls in the laboratories are built in a way to ease their dismantling. The resin floor is easy to repair and supplement in the event of a room rearrangement. The structure of the building itself allows for the implementation of new system shafts and, in those already made, there is a reserve for new installations. A reserve was also left for the installation of new systems on the technical terrace. All of these procedures will significantly reduce the time needed to install new laboratory equipment in the future.

Conclusion

Construction continues on three out of five buildings planned for the site. The final building (Wave Three) is in the design phase. Once completed, the ECR complex of health care facilities will comprise: an outpatient hospital with an operating theatre, a treatment unit and an IVF laboratory (Wave Two), a specialist inpatient hospital with a gynecology and obstetrics profile, a delivery and neonatal unit (Wave Three), and a rehabilitation center including hyperbaric and cryo chambers (Wave Four&Five). Construction is expected to be completed in 2023.

Team:

Investor: Invicta Clinics and Medical Laboratories

Architects: F A A B

Architects, project team: Adam Białobrzeski, Adam Figurski, Maria Messina

Assistant architects: Anna Miłosz, Mikołaj Szewczyk

Concrete structure engineers: Kappa Projekt

Steel structure engineers: PF Projekt

Electrical/Sanitary engineers: Profen

Photographer: Maciej Lulko

Materials Used:

Building mass and elevation. Process.

The eastern and western façades, finished with sintered ceramics, also required accuracy during assembly. In the case of both facades, the design envisaged the implementation of a three-dimensional form, intended to fracture and reflect sunlight. These elements are made of triangular, butt-joined panels. The panels are mounted with a specialised glue to steel consoles, the length of which is adjusted to the three-dimensional geometry of the façade. In order to maintain the uniformity of the façade material, the external window sills and the finish of the external window frames are also made of sintered ceramic.

Interiors. Inspiration and character.

Wood is the material that creates accents in the interior space. Selected because both its structure and colour depict the seaside location of the building.

Waterproof plywood, which is a traditional boatbuilding material, is present on the undersurface of canopy above the main entrance and penetrates into the internal main hall. It extends and continues the façade divisions and then bends in a soft arch at the wall behind the reception desk. Plywood is also present in the interior staircase. With it, a three-dimensional form was shaped that fills the soul of the stairwell. This form begins on the minus 1 level and extends upward to the roof terrace. It is divided into triangular fields and carved openings that enable users to perceive each other from both sides of the stairs. It recedes and grows, creating a sense of movement. On the roof, next to the technical terrace, which houses the technological heart of the building, a recreational terrace has been created. Thanks to a large opening in the eastern wall, this terrace ensures visual contact with the Bay of Gdańsk. The floor, seating steps and reclining benches are finished with larch wood. It was presumed that the wood should be left unfinished, without any impregnating agents. Knowingly, the material will turn grey over time under the influence of the weather. Then it will be similar in colour to the colour of one of the symbols of Sopot, a walking pier extending 458 meters into the Bay of Gdańsk.

Interiors. Inspiration and character.

The floor layout of two office levels, finished with a carpet tiles, is inspired by maritime theme. In each level, the basis for the composition is a painting with a marine accent. The image was converted into large pixels (50x50cm) and became an abstract colour composition that enlivens the space. A total of 24 colours were used to create a dipiction of 3 works depicting the coast adjacent to Sopot. The painting "Hel-boat", 1930, by Soter Jaxa-Małachowski, helped to create the composition on the first floor. "Bałtyk", 1938, author Soter Jaxa-Małachowski, on the 2nd floor. The painting "Waves", 1934, by Soter Jaxa-Małachowski, was the basis for the third floor carpet composition.