Trespa International B.V. is a leading innovator in the field of architectural materials, recognised internationally as a premier developer of high-quality panels for exterior cladding, decorative façades, and scientific surface solutions.

Since our founding in 1960, Trespa has worked closely with architects, designers, installers, distributors, raw material suppliers and end-users globally. Trespa’s focus is on product development, combining quality manufacturing technologies with intelligent solutions for architectural and scientific surface applications. With unique insights into key market challenges, trends and demands, Trespa is passionate about delivering innovative aesthetically pleasing and high-performance solutions for a wide range of needs.

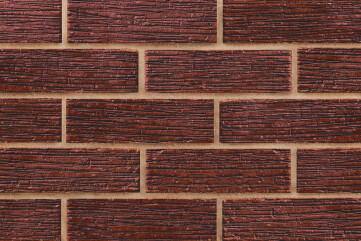

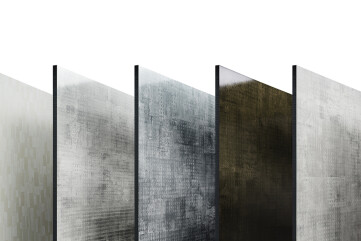

Trespa Product

Other Facades Products

Member Promotion