In April 2020, only weeks into the global pandemic, Enter Projects Asia based in Thailand, received an unexpected phone enquiry from Waregem, outside Brussels, Belgium.

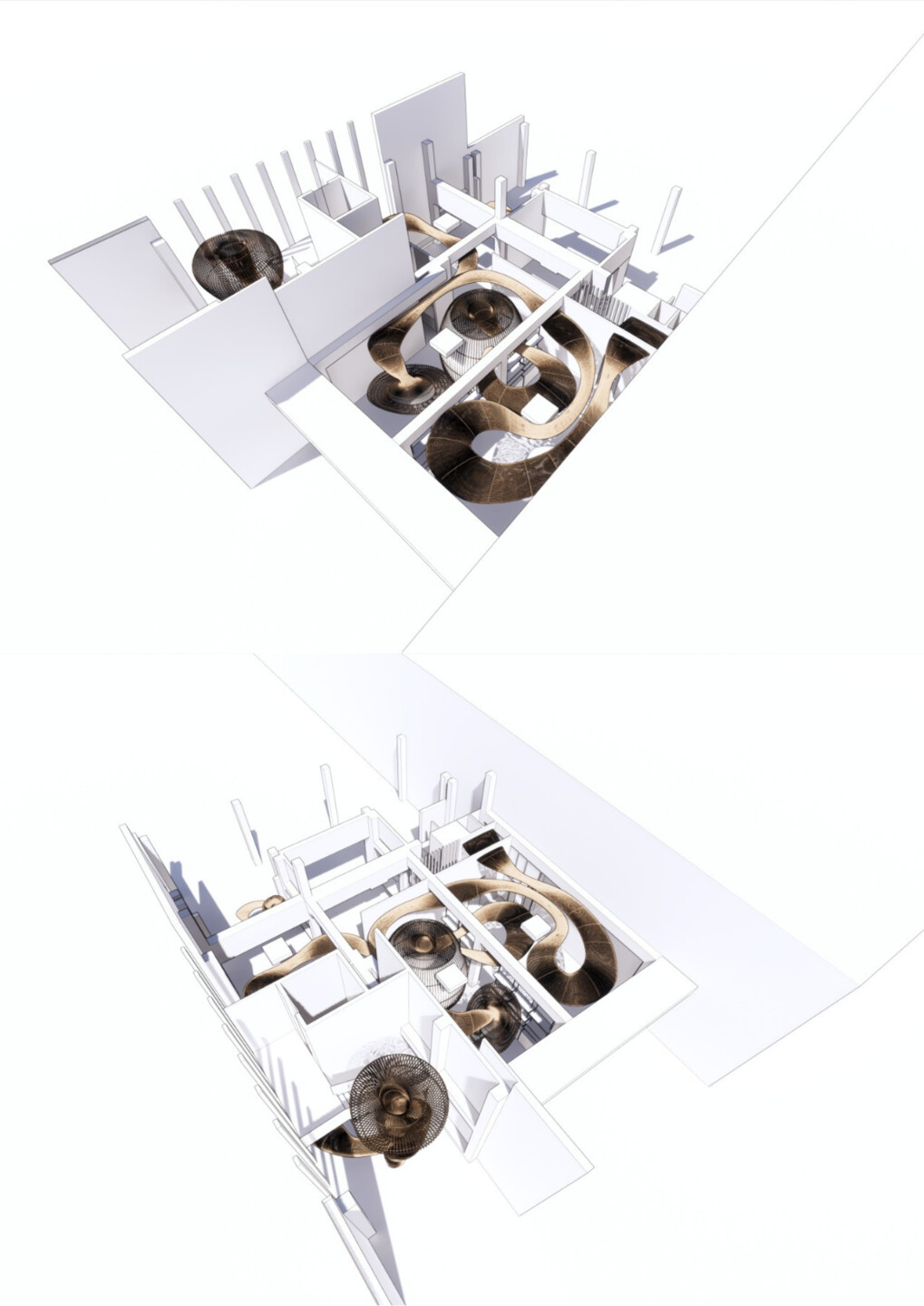

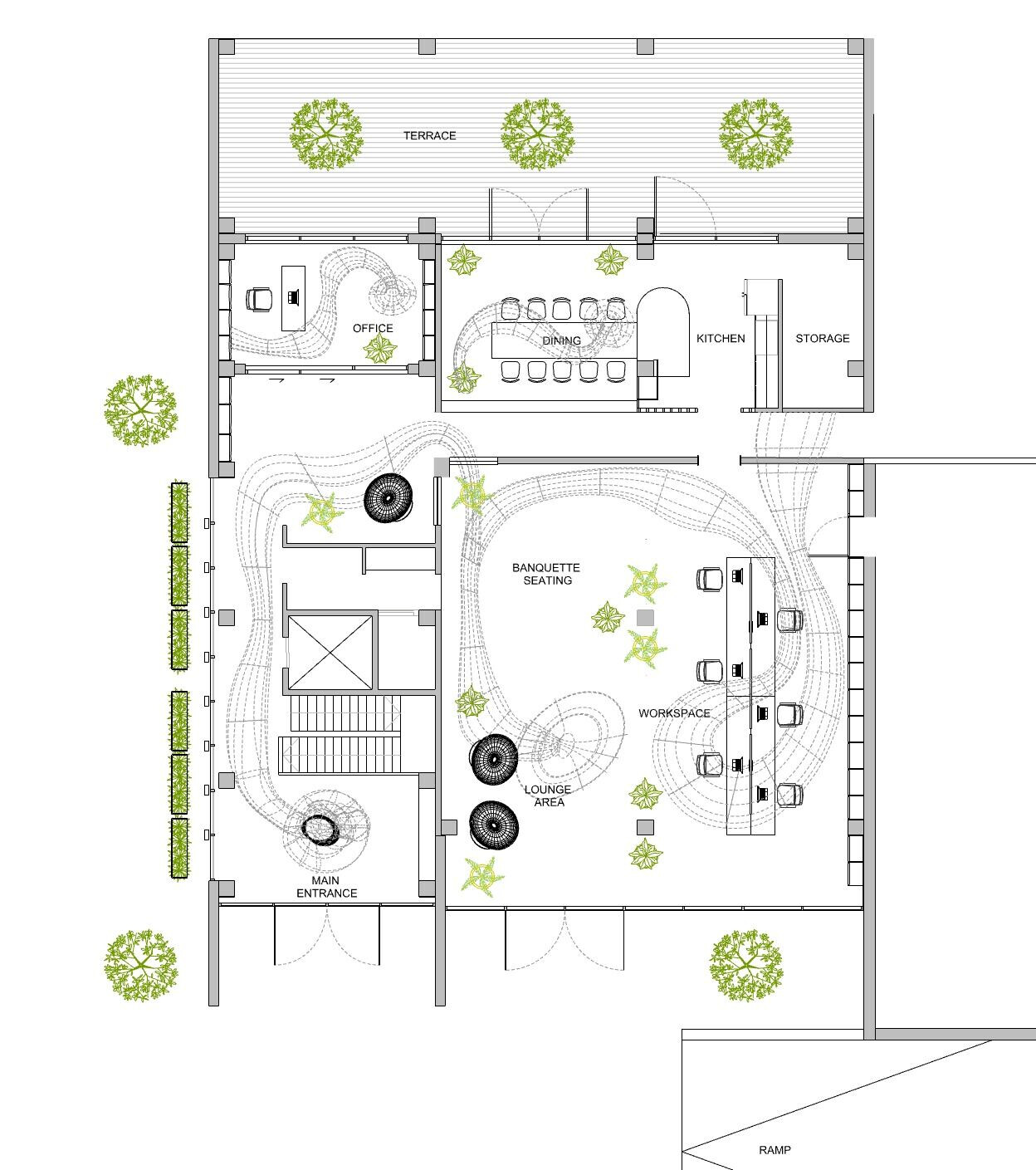

The prospective client had a 300sqm mix-use project that needed 'balance and calm'. EPA were given what felt like a 'wellness' brief for the space, inviting nature and creativity into an industrial setting. As the curtains came down on the world, EPA came up with a clear concept to meet the client brief. The site was an ice making factory so the design was to be fluid and liquid, like the properties of pure spring water crystallizing, incorporating raw and sustainable materials wherever possible. A highly innovative logistics program was essential if the vision was to be realized 9,000+km later at the final destination.

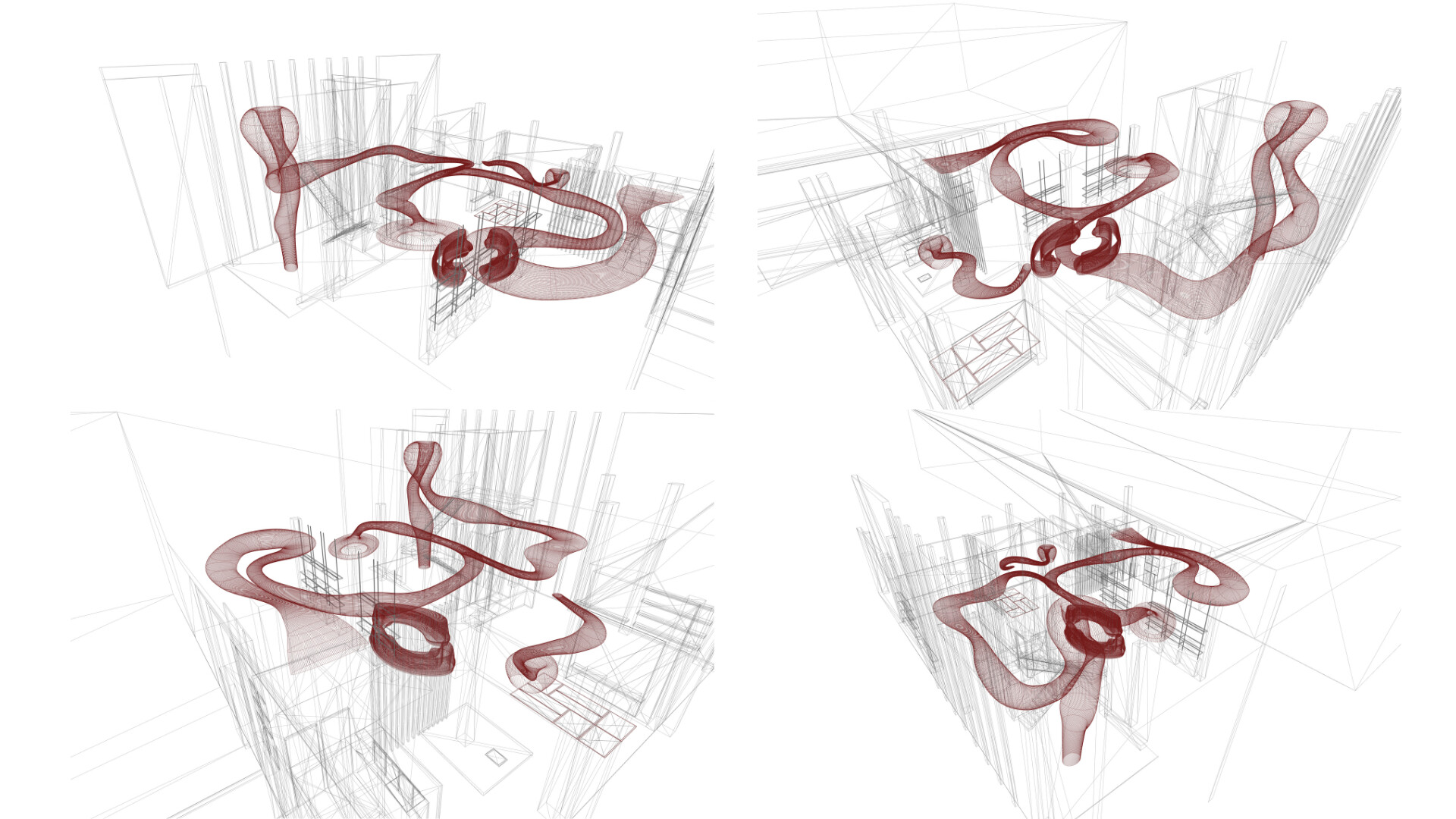

Relying heavily on Zoom for all client meetings & virtual site visits, the EPA team prepared for remote working. The Project Manager was operating out of Japan, the designers in Phuket & Sydney, the fabricators in Northern Thailand. The team never met. They remotely made templates, exchanged digital files and ultimately manufactured a series of sculptural elements in natural, sustainable rattan ready for Belgium.

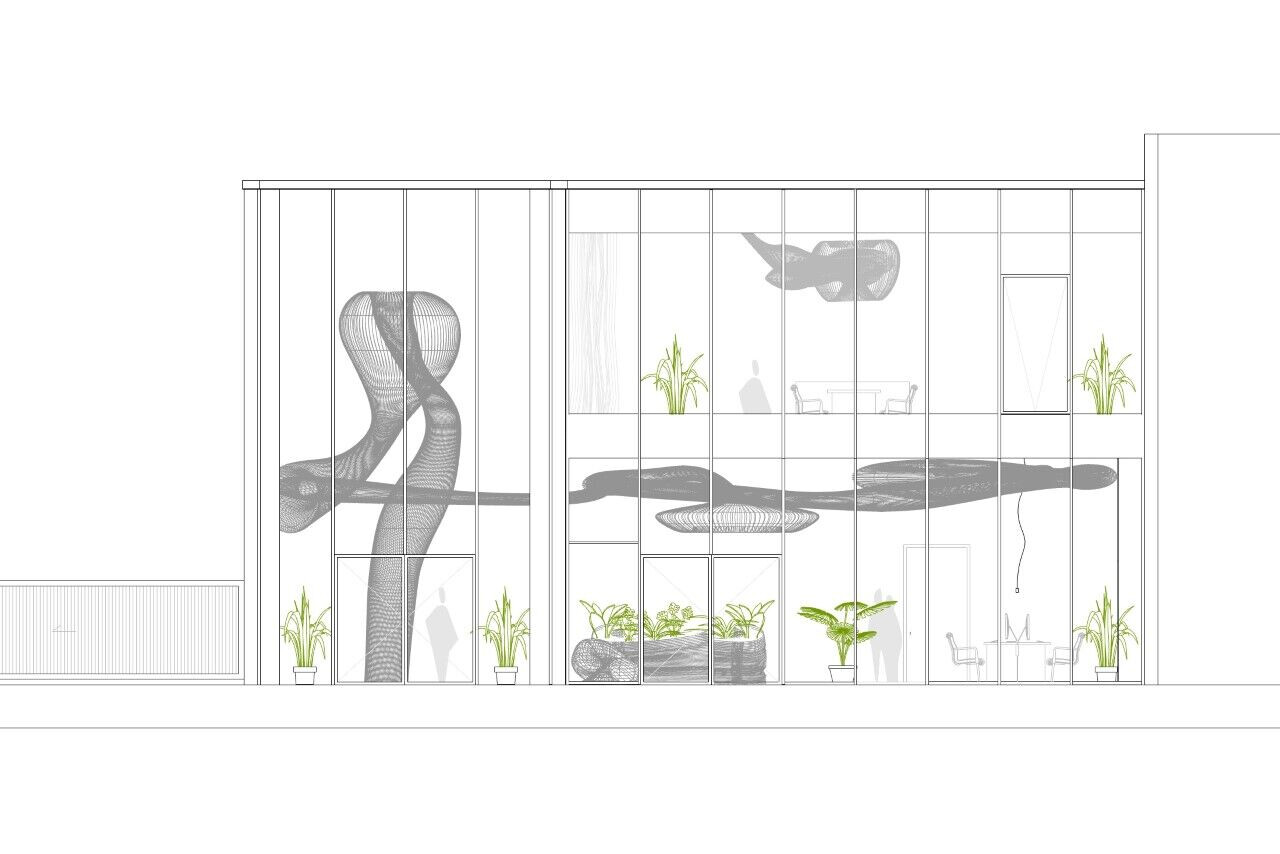

The sculptural segments were designed in accordance with the functionality: lighting, seating and directional flow, all culminating in a large 8 meter high sculptural statement piece which illuminates the lobby and compliments the image of the brand. As an overseas project, we had to come up with a highly innovative logistics strategy: every segment was then digitally deconstructed , so the shipping containers could be optimally filled. Like a 3d jigsaw, the segments were assembled on site in Belgium - with little to no room for error. "The detail and precision with which the client approached this task was incredible to witness, even from a distance", remarks EPA Director, Patrick Keane.

"Working across two continents always has its challenges" states Keane, "but this was on another level, nobody knew each other or exactly what the other was doing. It was a blank sheet of paper so given the result, I believe it’s the biggest and best challenge which often starts from zero''.

He also solemnly notes that "as a byproduct of this project, rattan factories were able to stay afloat during the darkest days: people were struggling to eat, supplies cut and shops closed. This project became a lifeline for many craftsmen who otherwise would have been without work. Maintaining these factories ensured local, sustainable arts & crafts production could continue".

In April 2022, with the project complete, the client & Architect finally met in person at the site. In a post pandemic economy these changing work practices have become the future as we learn to adapt, to reinvent what it means to lead from a distance. This project is not only a pioneer of the new work philosophy but also gives a new face to the factory as an innovative & creative workspace.

Team:

Achitects: Enter Projects Asia

Photographer: Edmund Sumner

Material Sustainability:

Use of natural materials prevents our biggest competition......plastic. The importation of inferior and often toxic plastic products is truly catastrophic to the environment. For interiors and furnishings especially on large scale hospitality & commercial projects, this is now at reckless levels.

• we encouraged a sustainable upgrade policy for this project using rattan on the interiors rather than synthetics

• rattan is grown in major abundance all over South East Asia. It has texture, tactility, warmth and all of the great qualities natural woods have with no threat or shortage.

• rattan is locally grown

• rattan is 100% biodegradable