A compact building for lease, off the corner of Hanatsubaki-dori Street and Ginza Corridor Street.

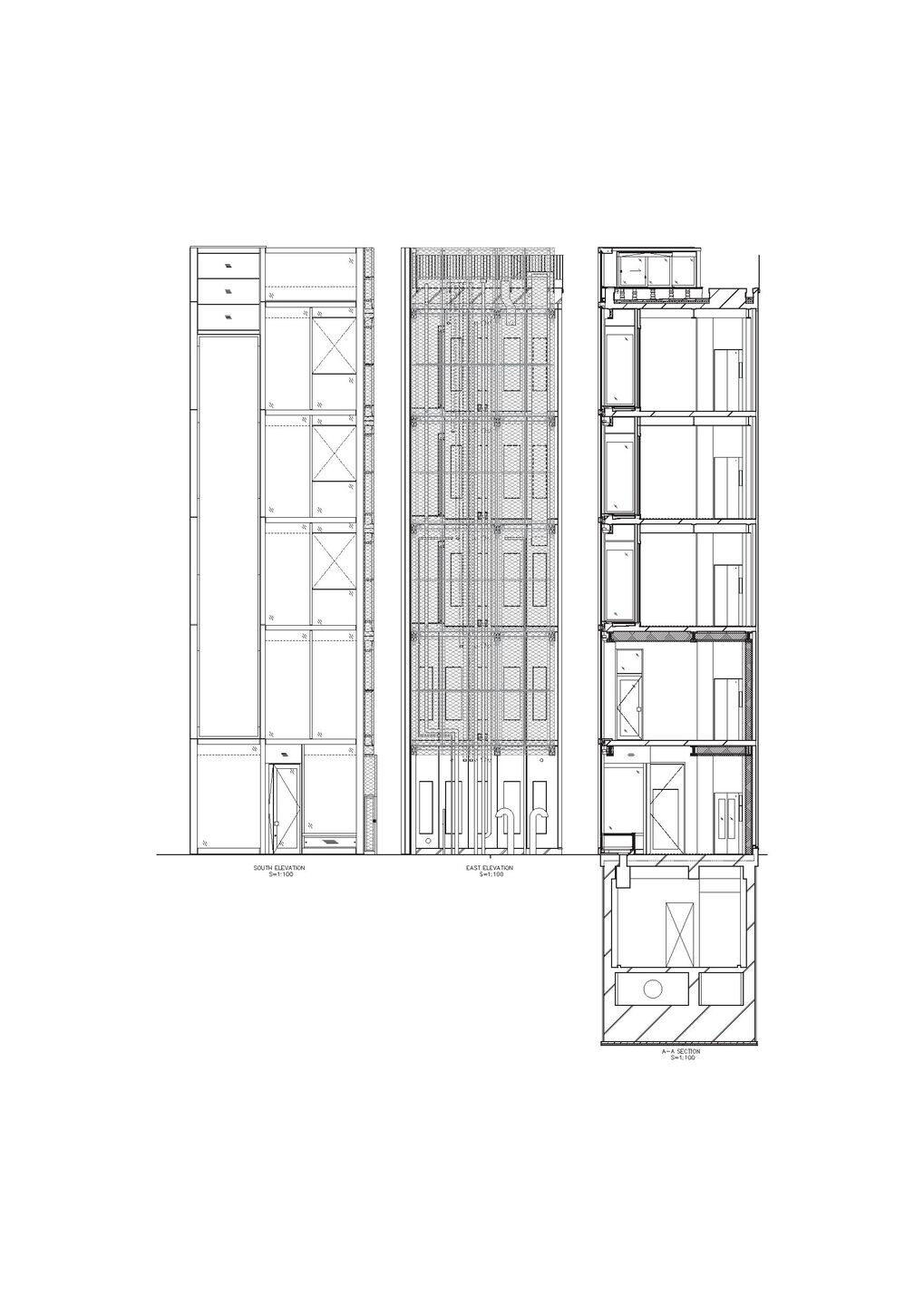

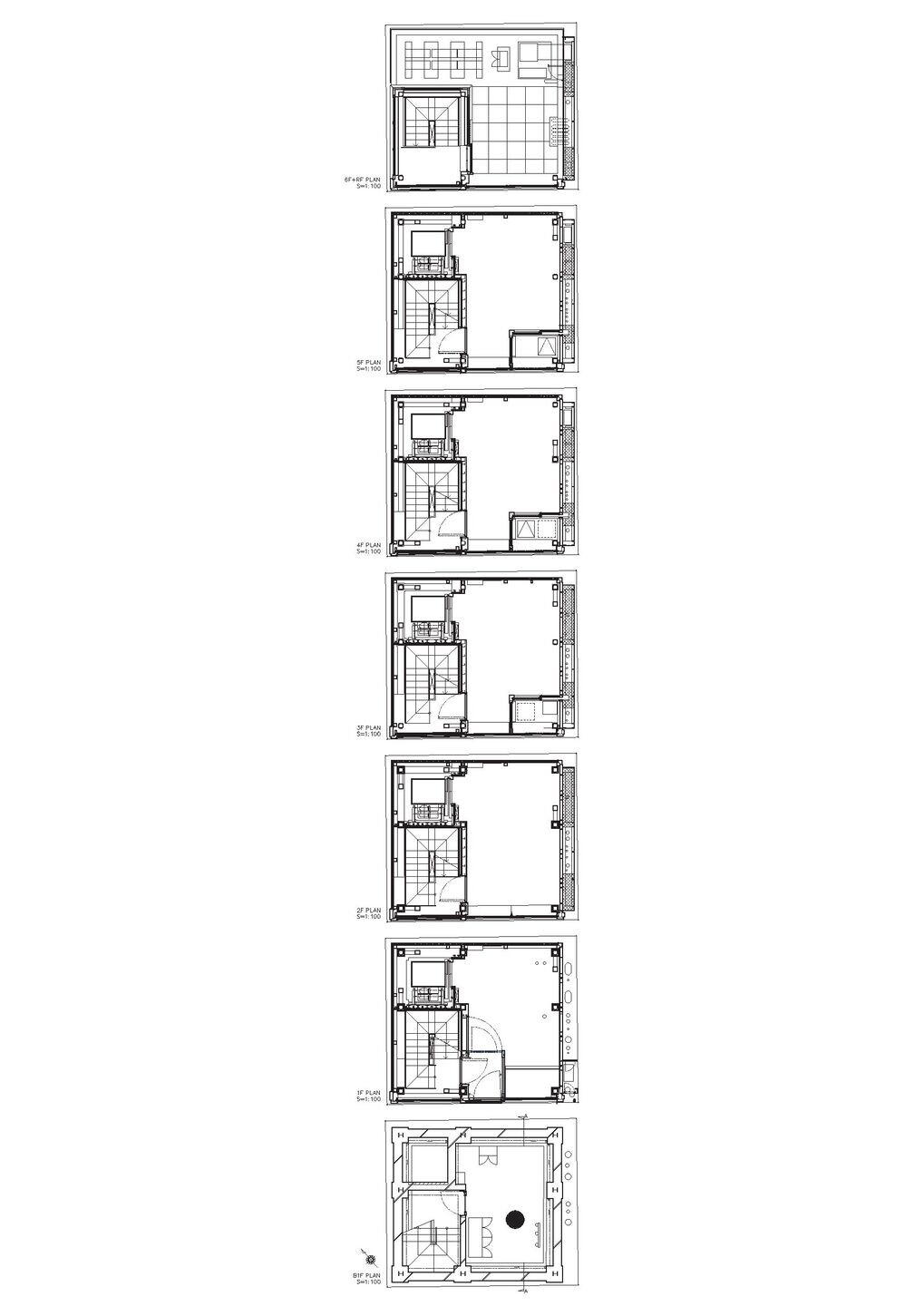

Tokyo’s famed Ginza commercial district commands the highest property values in Japan. Although the lot to be developed was only 6.27 metres wide by 5.46 metres deep, the relatively high value led to a detailed review of options to maximize rental income. If the design was to only be three-stories, there would be no requirement for an elevator, but this in turn limits leasing and rental options to only three floors. More stories would necessitate an elevator. Aligning the staircase and lift along the depth of the site and leasing each floor separately would require a common corridor that leaves the ground floor with hardly any leasable space. A lift and staircase across the width of the street façade would eliminate this common corridor requirement, although the street view from the inside would be blocked, and the required escape balconies on the third and higher floors could not be accommodated. The solution reached for this property was to master-lease the building with five floors above ground and a single basement below.

The design would incorporat the alignment of the staircase and elevator along the site’s depth, and an upscale restaurant, jewelry store, or watch store would be the target tenant.

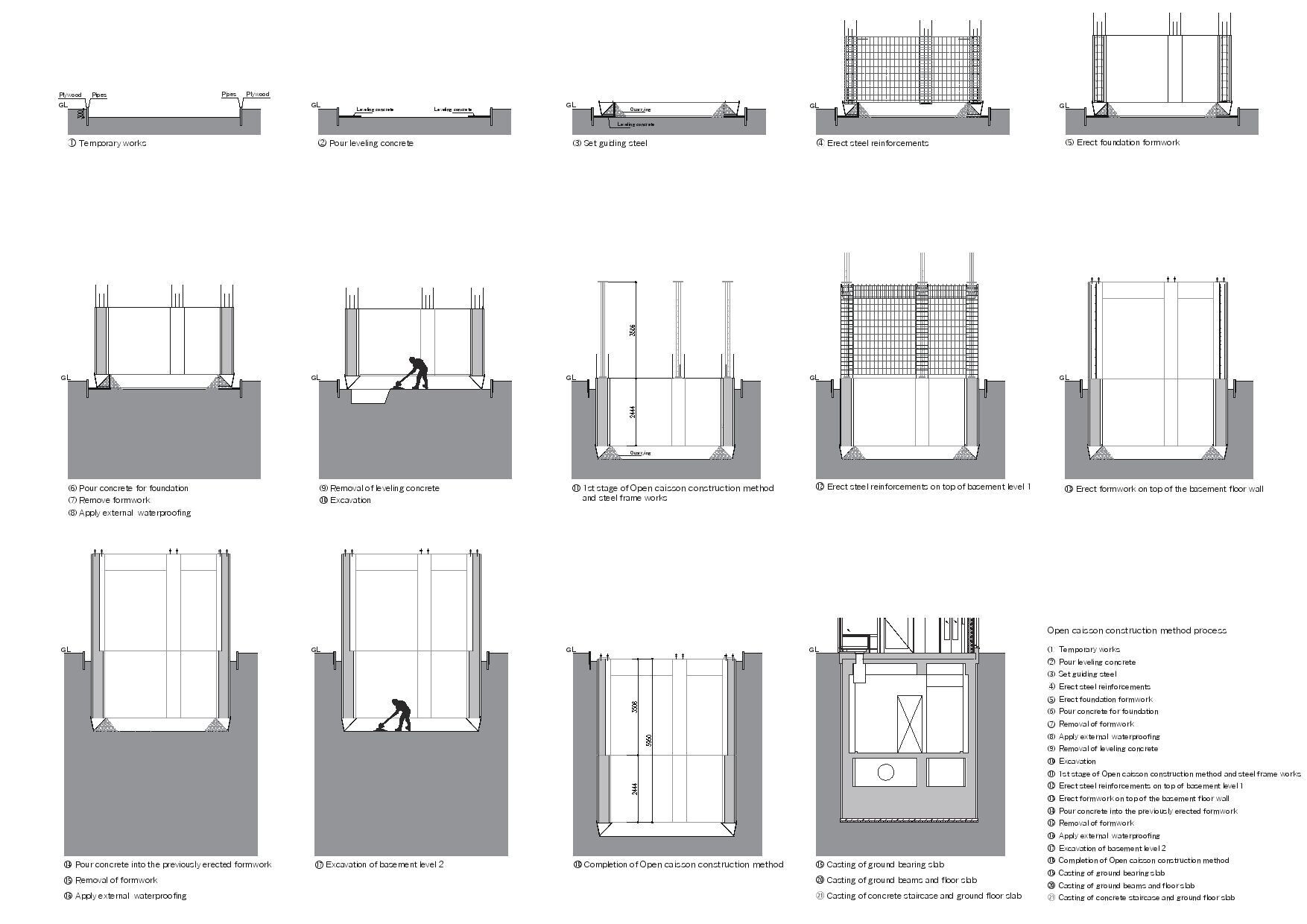

For the installation of the staircase and lift along the side of the building, the foundation wall below ground needed to approach the property boundary at a margin of only 200 mm. This prevented ordinary retaining-wall construction methods. An “open caisson construction method” was consequently adopted and executed as follows: The concrete foundation was precast as an open caisson, above ground on the site. The basement earth was then excavated and removed, which allowed the caisson to sink below ground level under its own weight. Having prior experience using this method with building construction, the general contractor, Ohara Komusho provided the expertise for this undertaking which is usually only employed in civil engineering. The underground foundation was designed to be 6 meters deep and rest directly on the load-bearing strata.

The first open caisson was poured 2.5 meters deep. To better facilitate sinking under its own weight, a tapered metal base was attached to sharpen the leading edges. Earth was then dug out from below the leading edges into the open caisson that functions as retaining walls on all sides. Once the 2.5m deep caisson was sunk far enough, a second open caisson was poured for the remaining depth of 3.5 meters on top and the foundation was sunk even further. The work to level the caisson while adjusting its horizontal position as it sinks is extraordinarily difficult. During the positioning of this foundation, earth at the base suddenly ebbed away, possibly due to groundwater flow, and induced an adjacent 70-year-old, three-story wooden structure with no foundation to sink. Despite the additional time spent to tear down the building on the neighboring property and adjust the caissons, the basement work was completed successfully after pouring the mat footing and plinth beams.

Due to the small footprint, the steel frame above ground needed to be as slender as possible. Thick-walled steel columns called “Kaku Hotto” in 150mm- and 125mm-square sizes were used. Fireproof coating called “Cera-tighca” was applied to the first and second floors in order to meet the required fire resistance rating of 2 hours, and fireproof paint with a resistance rating of 1 hour was applied to the third floor and above.

The basement comprises a storage and utility space that houses the electrical intake panel, telecoms cabinet, and drainage pipes. At ground level, a small space of about 50 centimeters was created on the west side of the site to install the water meter. Since space for the catch basins was difficult to secure, a recessed opening below the front window frame was created that provides this space and allows easy access. The staircase is installed at the front of the building and the route from stairs to exit door is very short for any emergency evacuation.

The west side of the building incorporates exterior conduit space that allows vertical travel of services and installing of air-intake vents. To allow separate tenant improvements later, the wall on each floor facing the exterior conduit space has fitted inspection panels for easy access. The conduit space is protected externally with a facing of expanded metal mesh.

The façade is finished with a gold color for an attractive, luxury feel. Back-illuminated, flexible plastic sheet signage is installed vertically in front of the staircase façade portion.

Although the roof balcony primarily houses external air-conditioning and exhaust-fan units, an open-air space provides a counter for eating and drinking and windows provide views of the street and nearby buildings.

Team:

Planning: Landpool Co., Ltd.

Design: Akira Koyama+KEY OPERATION INC. / ARCHITECTS

Structural Engineer: Delta Structural Consultants

Building Equipment: Comodo

Contractor: O’hara Architectural and Construction, Ltd.

Photography: Noriyuki Yano