Montenegro has a long and old history with religion and politics. Many Orthodox Christians retreated to the mountains in the 1600s to escape the Ottoman Empire, and this happened again during the great wars. Today, it is a thriving tourist and mining-based country with many mountain tunnels left unexcavated as shortcuts towards the Adriatic Sea.

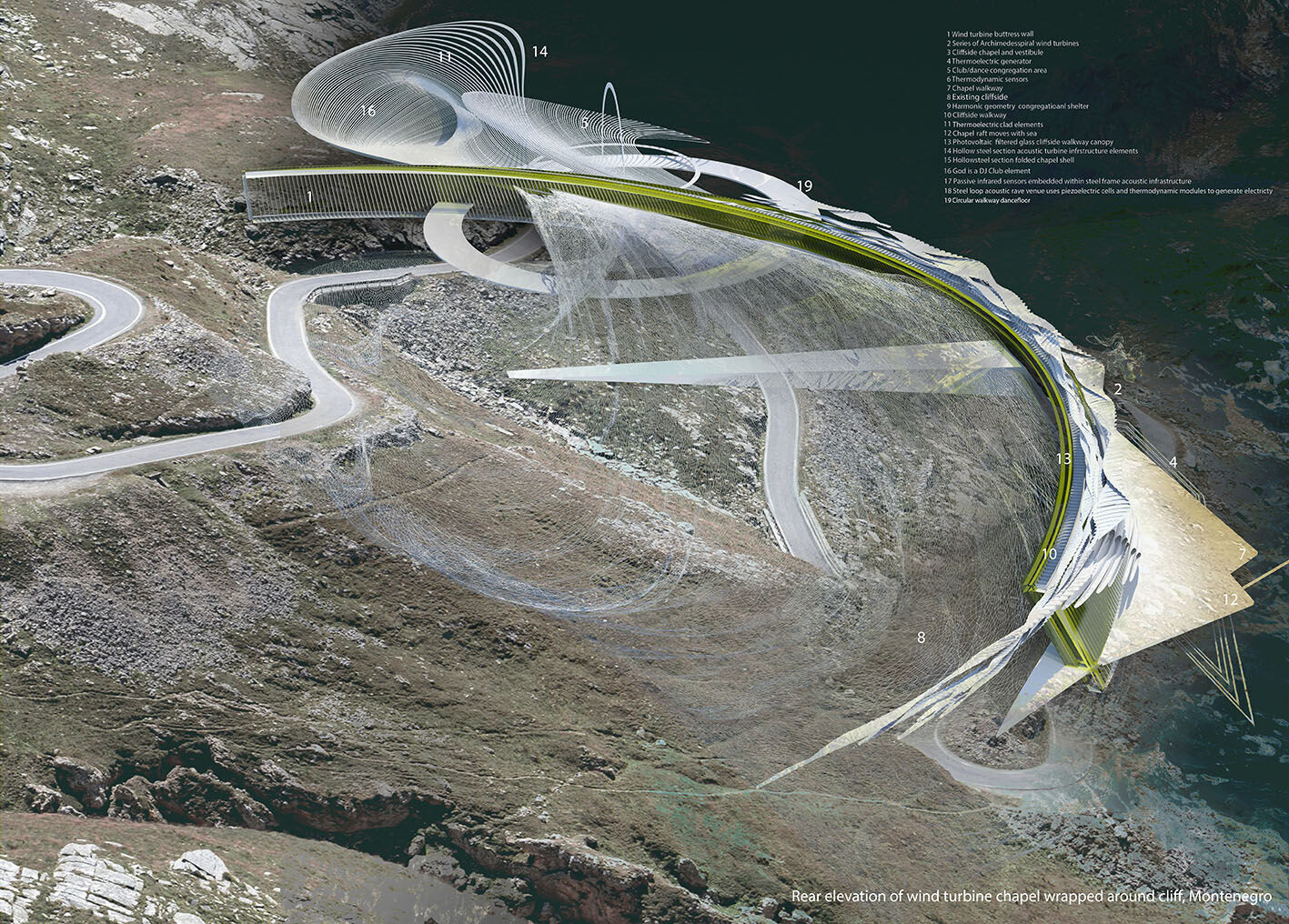

Pilgrimage to Ostrog, one of Montenegro’s most famous cliffside churches, is still being undertaken today. Montenegro has a varied and, at times, treacherous and dangerous landscape; the country borders Serbia and Albania and has vertiginous mountain ranges, dense dark forests, mountain plains, valleys (canyons and gorges) and basins; a dynamic physical geographic basis and strip of the Adriatic coast. Tourists, worshipers and families visit yearly, where most drive into one of the coastal towns for vacation. The dangerously sinuous roads are responsible for many accidents and deaths, with shrines dotted along them. The country is steeped in harrowing tales of bloodshed etched into the landscape. The project respects the region’s natural beauty but considers the tough and inhospitable landscape, suggesting a more aggressive, dynamic approach to the design.

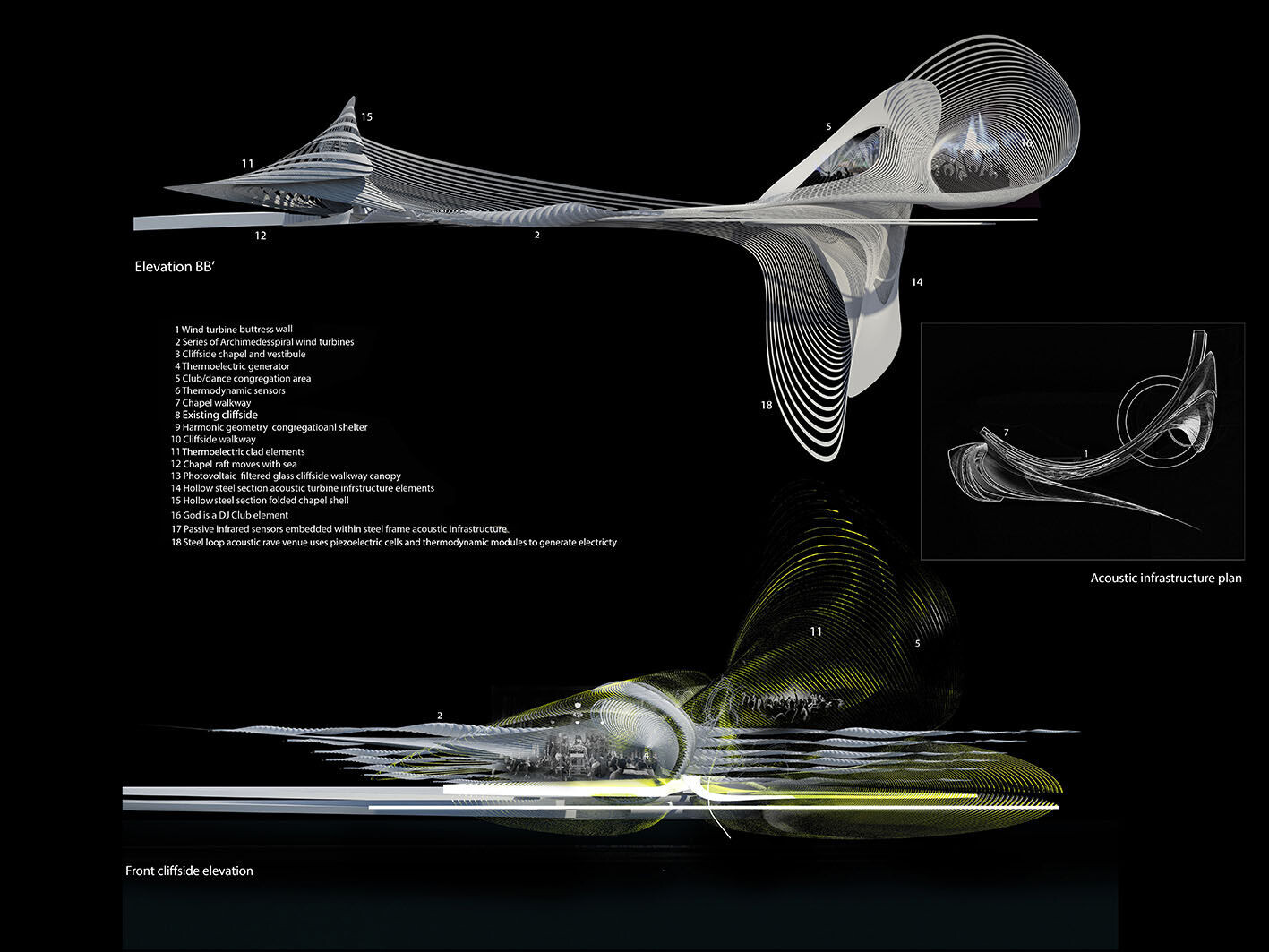

The project brief brings renewable energy to the worshipping communities by designing a cliffside chapel. Montenegro has a prevailing wind called Bora, fastest at the highest peaks, embracing the cliffsides by running along them. The site is a disused, partly constructed tunnel with the retaining cliff walls built. Located between Kotor and Budva, I combined the summer music festivals and raves popular in the area with a chapel, a type of renewable energy gathering—a congregation.

The Bora, prevailing wind, reaches 100 mph at the highest latitude; the architecture choreographs the wind through the wind turbine channelled walls. The wind turbines are positioned in series to accelerate the speed when passed through differing cross-sections within the chapel design, increasing speed and efficiency. The building uses Archimedes spiral turbines as they are more resilient and better suited for the Montenegrin environment’s characteristics. These turbines are less complicated to lean and are weighted differently to minimise backwind interference between the turbines, which will slow down and prevent maximum energy output.

The church uses the idea of a congregation, a gathering of people to unite for self-expression and worship, echoing nearby raves and music festivals held along the coast, as well as Ostrog cliff church. The concept is to design spaces and platforms to bring people together using their kinetic movement and heat to generate electricity by employing thermodynamics and piezoelectricity along with wind energy, bringing sustainability from renewable energy to the remote areas of Montenegro. At times, the treacherous landscape with vertiginous heights can be unwelcoming to occupy, yet with a strong sense of history and community, this becomes possible with the thermodynamic wind turbine chapel venue since the generated surplus energy lights up the dangerously curved roads leading drivers to the Adriatic Sea from other nearby cities. The typology of the chapel focuses on renewable energy and congregation. Worship, music and dance come together in one building.

Technical sheet

Official name of the project: Thermodynamic wind turbine chapel and club

Location: Montenegro, Kotor

Client: SHANGHAIMETAL

Architects/Designers: Margot Krasojević

Project manager: Margot Krasojević

Collaborators: Out to tender

Thermoelectric materials

Thermoelectric materials, like conducting polymers, convert thermal energy into electrical energy when exposed to temperature increases. Gallium nitride, a semiconductor, is used as a pyroelectric crystal. Semi-conducting materials applied to be confirmed.

Piezoelectric cells

Piezoelectric cells are embedded in dance floor mats, PIEZO, Chinese production.

Composite carbon fibre

Composite carbon fibre reinforced Polymer composite interior vaulted shell cladding. Elite Carbon Fibre manufacturers, U.k/Beijing

Anti-vibration vacuum bagged composite fibre shell insulation

Placed between interior and exterior frame.

Epoxy laminate molds for fibreglass construction.

Pressure sensitive tapes for brake testing facility- Matrix composites, U.K./Beijing

Technical textiles

Technical textiles applied to inner lining of cantilever cladding, lighter than aluminium for weightlessness and resilience. Textile fibre materials determine stability through 45 degree torsions for track expansion. The material adapts to the external forces of the cantilever and its movement.

Carbon fibre

Carbon fibre reinforced plastics allow for complex shapes more than steel or aluminum. weight saving. resin saturated cured elements, achieving lower weight for the cantilever.

7. 3m optical mirror film, light transmission. polymer film exhibits 99% light reflectance for interior and exterior cladding elements used in viewing tunnel and atrium surfaces.

Interior materials

Polyester films transform between transparent and translucent states dependent on viewing angles, anti-reflective privacy films.

Self healing polymers

Self healing polymers are used to support internal mechanisms, sliding seamless surfaces and load transfer attachments between skin and skeleton of expanding race track. This structural deformity under load catering the telescopic composite fibre sections has a series of polymer sheets which protect the design from wear and tear as the tracks slide apart to reveal the atrium.

Motion capture system

A motion capture system between the primary and tertiary structure record the movements of vehicles, which allows the facility to virtually synchronize with vehicle movement and performance.

Light transmission

Light transmission is very important in the viewing tunnels and barrel-vaulted facility which is why acrylic is beneficial to the design along with PLEDS, enabling thin lighting displays with superior effect and simplicity to LCD'S. These Polymer Light Emitting Diodes are also used in the surrounding landscape of the proving ground to transform the interior environment as necessary.

Telescopic track shell sections

Telescopic track shell sections are lined with composite carbon fibre impregnated with epoxy resin.