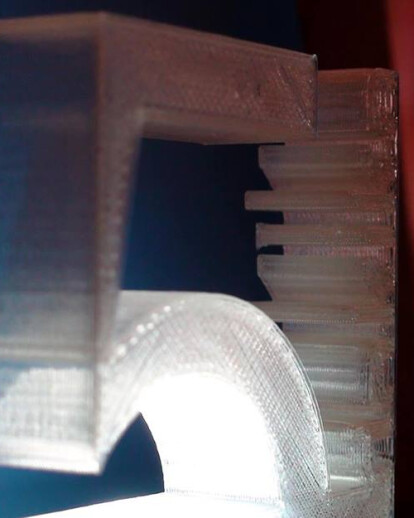

3D Printing is named after rapid prototyping machines that emerged in the 80's. It's also known as additive production. This revolutionary method to produce 3 dimensioned objects is now a global phenomenon to manufacture unique pieces because of the convenience it brings to design and manufacture.

The steps of 3D printing are as follows: • The object is modeled digitally in 3D in a CAD program • The model is sliced with a software that will communicate with the printer as G code steps • The G code is transferred to the printer • The 3D printer is ready to effuse the given layers / slices in the given order and quantity on its platform • The 3D printing process duration depends on the complexity of the model and the resolution / quality of the final print • Different 3D printers may use different materials

The advantages of 3D Printing • Unique item production • Fast prototyping that satisfies functional criteria • Minimum material use • Limitless customization possibilities • Rapid change and adaptation on products • Non-toxic and recyclable material use such as PLA • Any kind of partial production independent from the whole