Concept

The waste-to-energy plant, Amager Bakke / Copenhill, is located in an industrial area, that throughout the years, has turned into an extreme sport destination for thrill seekers. Different extreme sports activities take place in the raw industrial facilities such as cable wake boarding, go-kart racing, and rock climbing among others. Amager Bakke / Copenhill is the most significant landmark in the area and the building is in need of renewal. We propose a new breed of waste-to-energy plant, one that is economically, environmentally, and socially profitable. Instead of considering Amager Bakke / Copenhill as an isolated object, we mobilize the architecture and intensify the relationship between the building and the city—expanding the existing activities in the area by turning the roof of the new Amager Bakke into a ski slope for the citizens of Copenhagen.

The new plant establishes Amager Resource Center as an innovator on an urban scale, redefining the relationship between the waste plant and the city. It will be both iconic and integrated, a destination in itself, and a reflection on the progressive vision of the company.

PROJECT DESCRIPTION

CopenHill, also known as Amager Bakke, opens as a new breed of waste-to-energy plant topped with a ski slope, hiking trail and climbing wall, embodying the notion of hedonistic sustainability while aligning with Copenhagen’s goal of becoming the world’s first carbon-neutral city by 2025. CopenHill is a 41,000m2 waste-to-energy plant with an urban recreation center and environmental education hub, turning social infrastructure into an architectural landmark.

CopenHill is conceived as a public infrastructure with intended social side-effects from day one. Replacing the adjacent 50-year old waste-to-energy plant with Amager Ressourcecenter (ARC), CopenHill’s new waste incinerating facilities integrate the latest technologies in waste treatment and energy production. Due to its location on the industrial waterfront of Amager, where raw industrial facilities have become the site for extreme sports from wakeboarding to go-kart racing, the new power plant adds skiing, hiking and rock climbing to thrill seekers’ wish lists.

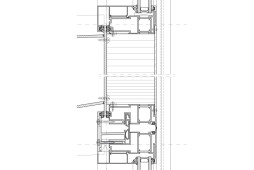

The internal volumes of the power plant are determined by the precise positioning and organization of its machinery in height order, creating an efficient, sloping rooftop fit for a 9,000m2 ski terrain. At the top, experts can glide down the artificial ski slope with the same length as an Olympic half-pipe, test the freestyle park or try the timed slalom course, while beginners and kids practice on the lower slopes. Skiers ascend the park from the platter lift, carpet lifts or glass elevator for a glimpse inside the 24-hour operations of a waste incinerator.

Recreation buffs and visitors reaching the summit of CopenHill will feel the novelty of a mountain in an otherwise-flat country. Non-skiers can enjoy the rooftop bar, cross-fit area, climbing wall or highest viewing plateau in the city before descending the 490m tree-lined hiking and running trail within a lush, mountainous terrain designed by Danish Landscape Architects SLA. Meanwhile, the 10,000m2 green roof addresses the challenging micro-climate of an 85m high park, rewilding a biodiverse landscape while absorbing heat, removing air particulates and minimizing stormwater runoff.

Beneath the slopes, whirring furnaces, steam, and turbines convert 440,000 tons of waste annually into enough clean energy to deliver electricity and district heating for 150,000 homes. The necessities of the power plant to complete this task, from ventilation shafts to air-intakes, help create the varied topography of a mountain; a man-made landscape created in the encounter between the needs from below and the desires from above. Ten floors of administrative space are occupied by the ARC team, including a 600m2 education center for academic tours, workshops and sustainability conferences.

Rather than consider ARC as an isolated architectural object, the building envelope is conceived as an opportunity for the local context while forming a destination and a reflection on the progressive vision of the company. CopenHill’s continuous façade comprises 1.2m tall and 3.3m wide aluminum bricks stacked like gigantic bricks overlapping with each other. In-between, glazed windows allow daylight to reach deep inside the facility, while larger openings on the southwest façade illuminate workstations on the administrative floors. On the longest vertical façade, an 85m climbing wall is installed to be the tallest artificial climbing wall in the world for new world records to be broken with views inside the factory. At the bottom of the ski slope, a 600m2 après-ski bar welcomes locals and visitors to wind down once the boots are off. Formerly a piece of infrastructure in an industrial zone, CopenHill becomes the new destination for families, friends and celebration, one that is economically, environmentally and socially profitable.