Researchers from the FHNW Academy of Art and Design and woodwork specialists from ERNE AG Holzbau have created a new process to design and manufacture high-quality custom wooden facades. Through a combination of traditional craft knowledge with novel manufacturing technology and interdisciplinary collaborations, architects gain the freedom to develop unique façade solutions and clients to acquire outstanding architecture for an affordable price.

CoDe Façades is an innovative process to design and fabricate unique, cost-efficient, and well-crafted wooden facades offered to architects and clients by a Swiss wood construction company. It was developed as a research project between the FHNW Academy of Art and Design and ERNE AG Holzbau in response to the growing need for flexibility and adaptability in the construction industry while keeping the high quality of the final product.

This system comprises three innovations applied in the industrial setup, resulting in an efficient and flexible design-to-production workflow. (1) The collaborative design approach is a method in which the architect, engineer, and manufacturer exchange on the early stage of the project during the design workshops. (2) Digital design and fabrication tools enable architects to generate a large scope of façade variations within the production feasibility of the manufacturer and engineers to prepare files for robotic production. (3) Novel multi-robot fabrication processes allow for complex façade assembly.

Digital craftsmanship

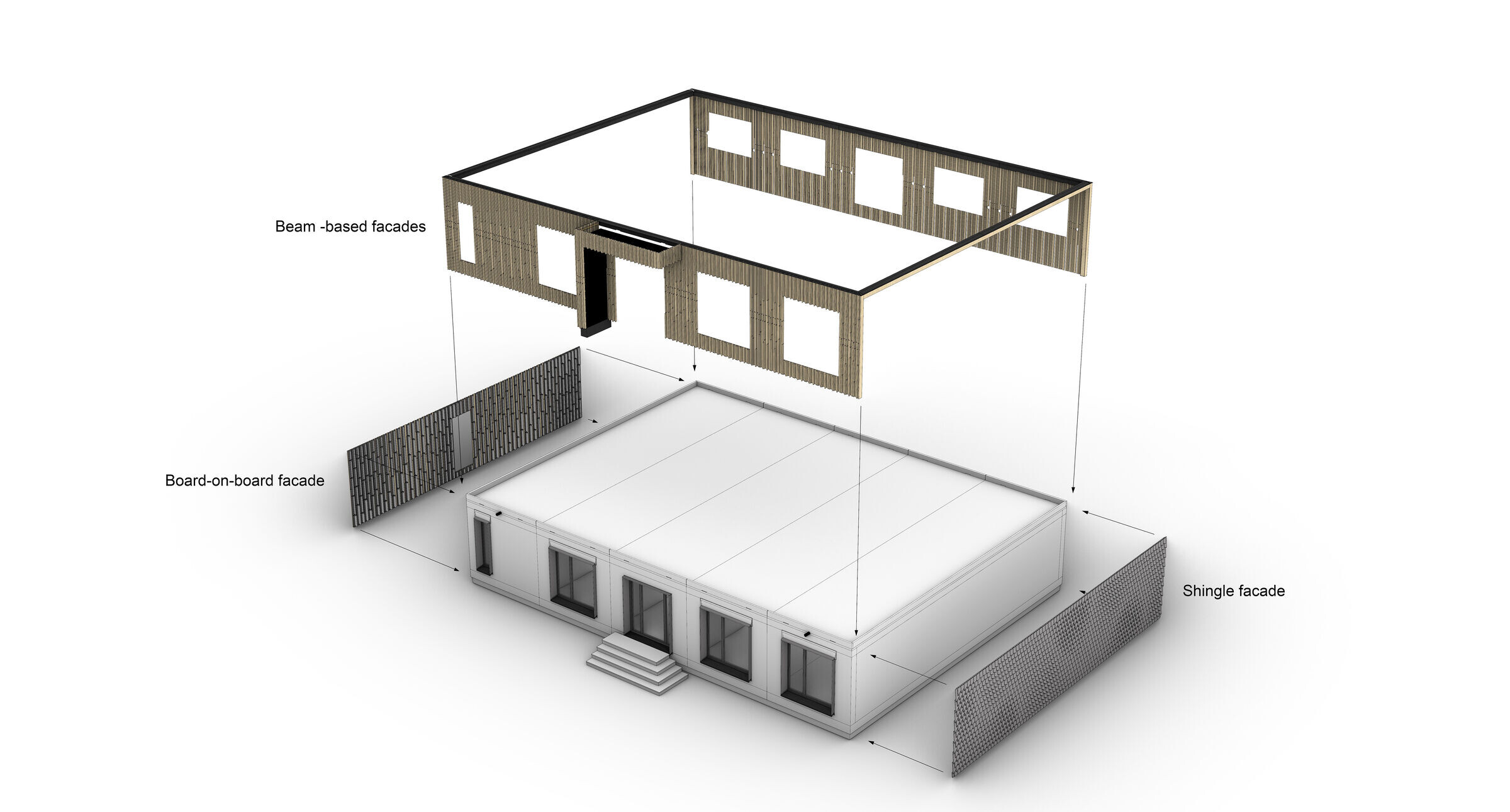

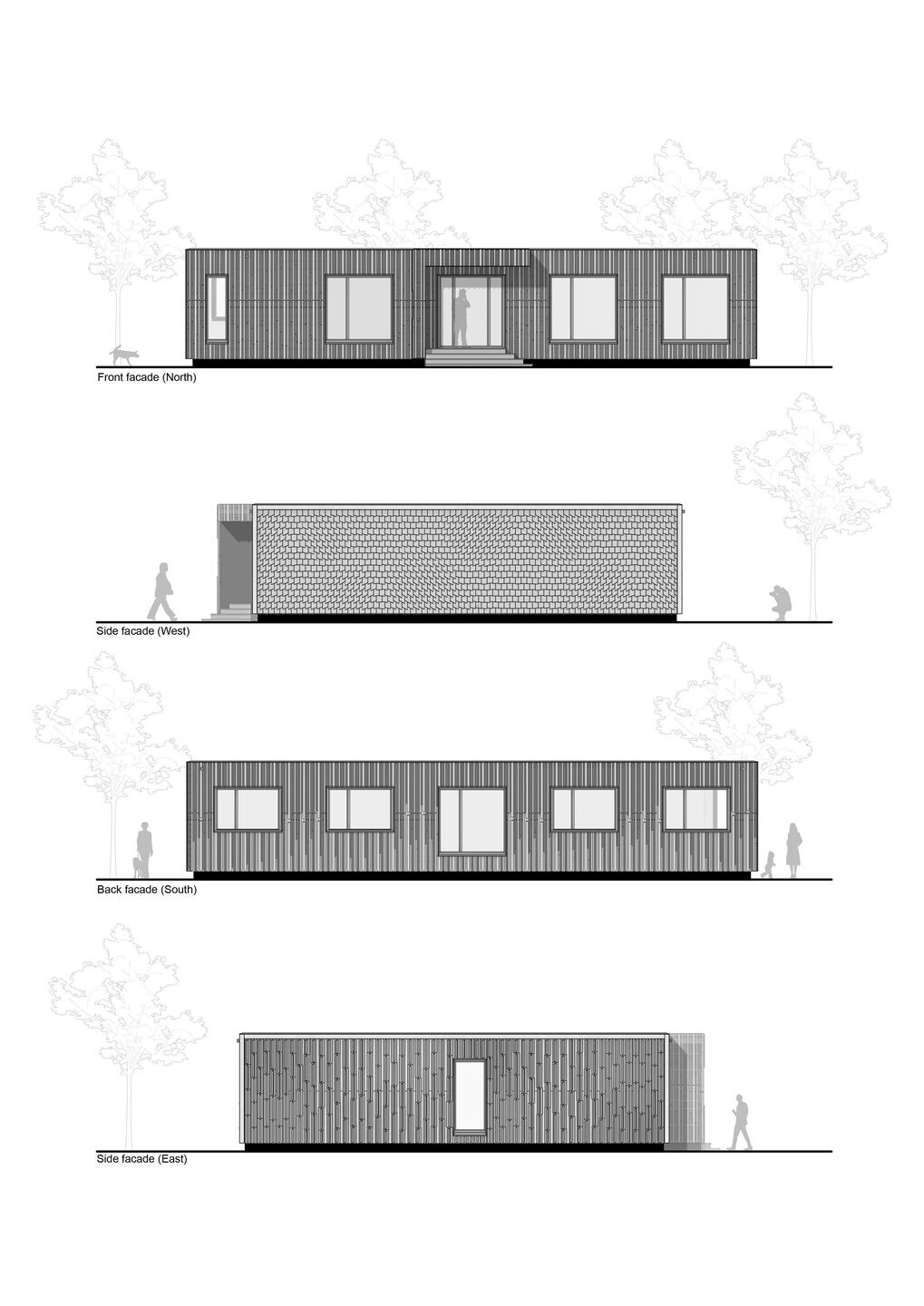

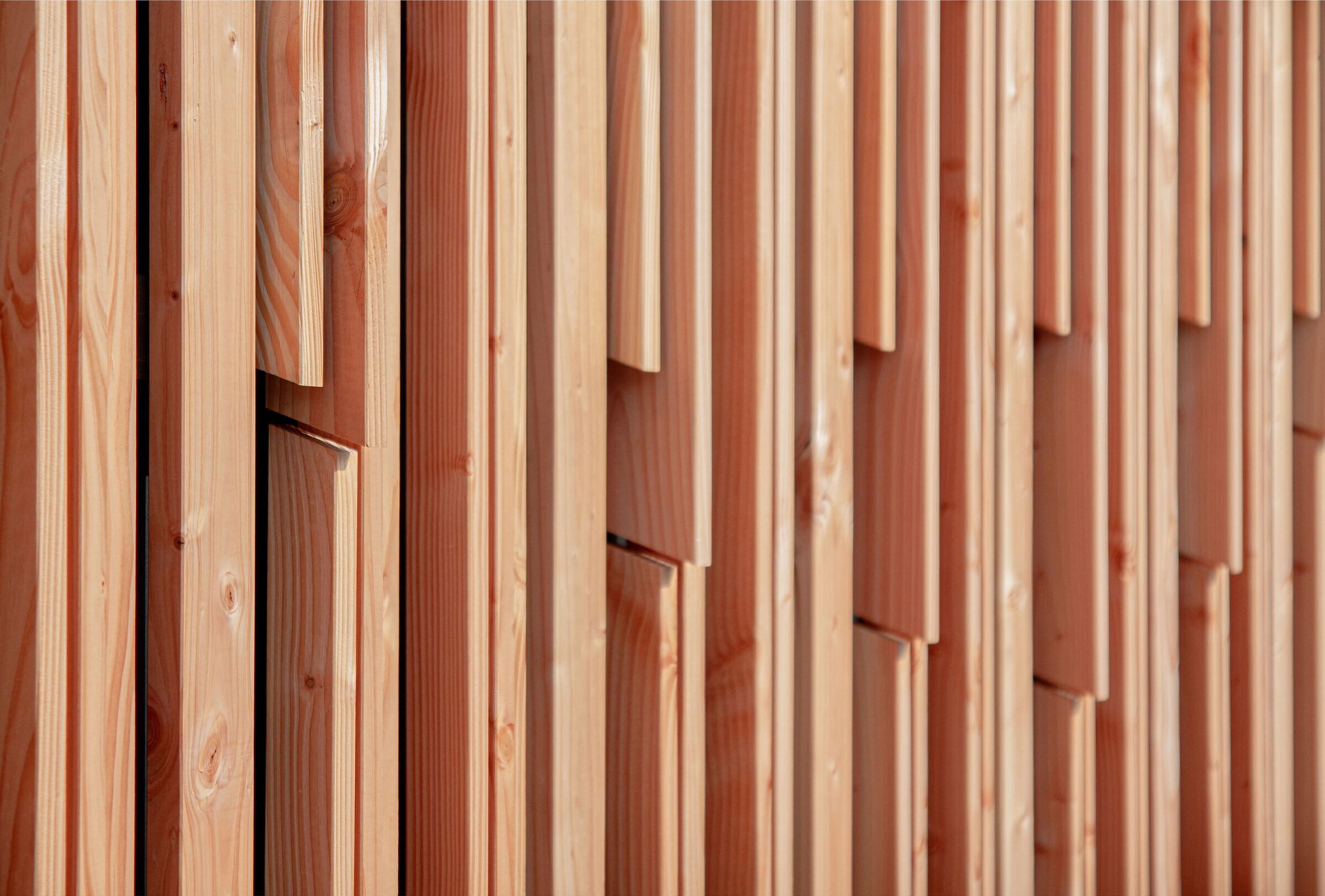

CODE Facades introduced the concept of craftsmanship enhanced through digital means as a new value in the industrial realm. It can be observed on multiple levels. Firstly, the design space offered to architects was derived from rich Swiss woodcrafts tradition. The three most typical façade families: beam-based, shingles and board-on-board, have been digitally reinterpreted and aesthetically expanded while keeping their original logic and performance.

Secondly, the system uses mixed fabrication, which intelligently combines automated and manual production. While the robotic processes improve precision, efficiency and speed of construction, the material quality and surface finishes are ensured by the manual skills of the ERNE's carpenters. This increases the quality of the facades and lowers and cost of production. Such an industrial setup, often associated with affordable and standardized solutions, is enriched with new values of crafts and individuality.

Lastly, the proposed process brings architects closer to making. By using integrative digital tools and through close collaboration with an industrial partner, architects can take a more active role in the construction sector and design with more awareness of manufacturing.

Facades of office Saig

The architectural potential of the system has been validated through the full-scale application on four facades of a 1-storey-high temporary office building in Stein, Switzerland, with a total area of 220m2, constructed in November 2020. Inspired by local traditional solutions, its intricate facades stand out in a local industrial context.

Summary

The system's innovation lies in the introduction of design-driven flexible automation strategies into the industrial setup. These include an early exchange between architect and manufacturer, flexible digital design tool and reconfigurable fabrication setup.

Where manual techniques would be impossible to implement or require custom-made formworks and complicated individual treatment of each element, the computational and fabrication methods offer flexibility, efficiency and high quality. This quality distinguishes the developed system from individualized expensive façade solutions currently available on the market.

Acknowledgments

CoDe Facades was developed within an applied research ‘CoDeFa’ (Collaborative Design of Prefabricated Façade Systems), between FHNW Academy of Arts and Design and ERNE AG Holzbau, co-financed by Innosuisse.

Credits:

Institute Integrative Design | Masterstudio (currently Institute Contemporary Design Practices), HGK, FHNW:

Edyta Augustynowicz (Project Lead), Maria Smigielska, Daniel Nikles

(Architectural design/ Parametric process development/Robotic process development)

Ralf Michel, Heinz Wagner (Academic advisory)

ERNE AG Holzbau:

Thomas Wehrle (Project Manager)

Oliver Ackermann, Heiri Treier, Thomas Reiner (Wood Engineering/ Wood Manufacturing and Construction/ Facade assembly)

Project support:

Innosuisse - Swiss Innovation Agency.

https://codefacades.ch/