Diagonal 80 is a company that converts digital files into physical objects of all sizes and materials in printed formats. It is a paradigm of the new firms in the digital world: medium-sized, constant technological updates, flexible hours, 24 hour service… its workspaces range from the typical tertiary computer zones to large-scale industrial spaces, all scattered amongst different offices and locations; they do not need a central or specific location because a large percentage of the work is managed across the Internet. To unify these locations outside the city, the new building is a hybrid between an industrial pavilion and a tertiary space: in spite of the industrial dimensions and finishes, the interior lighting and environment conditions are fully controlled to preserve the sensitive equipment.

The spatial system consists of four main groups of components: a bearer system linked to its tension and geometry; the exhibition system for the products —printing on canvas, vinyl and stiff backing material—; the interior climate control machinery and ducts; and the outer skin, a conventional metal enclosure system without a substructure. This suite of four families of components is governed by a common geometric system that defines the spatial configuration.

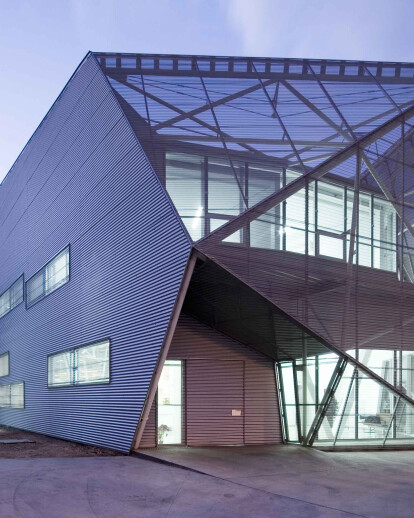

A longitudinal building is proposed to make the most of the narrow site and the permitted construction ratio. It is polarised by the entrance from the industrials estate roadways, and hence by its commercial presence, as well as by the views of the natural environs of the Guadalix River and the mountain backdrop. The perimeter is determined by a system of opposing forces that are balanced between the setbacks and the alignments, the turning vehicles, the entrance location and the relative position of each of the company sections inside.

The addition of a single feature gives the system its sense and its geometric, structural and spatial stability. This is a single double Y shaped piece that forms hexagonal shaped grids, adapting to the variable spans and its different positions. Through a differentiation process, the initial piece turns into the columns for three floors, the beams for the roof and the floors below, the stairs, the props for the awnings outside and the connecting items between floors: at these points, the initial geometry adopts changes and specialisations. Vertically, the items interconnect at the top, merging and interlacing to gain stiffness while becoming lighter below, resting on the smallest possible number of points on the ground. In the case of the horizontal members, they are substressed below to bear the load of the structure, and where exposed in the exterior, they support the tensed canvas. The same summatory logic is applied to the vertical members —upright beams— that enclose the stairs and the voids that arise as a deformation of the slab geometry.

The geometry is a combination of triangulations, beams and bifurcated columns, with linear units that selectively stiffen the bearer system. The horizontal substressed beams bridge the decreasing width of the site in a single span and bifurcate when they reach the perimeter of the building. The aim is to rescue lightweight three-dimension structures from oblivion and use them in applications that go beyond lightweight roofs and enclosures, recovering the role of a space configurator for the bearer system: space equals structure.

Outwardly, the building takes on the appearance of the industrial vernacular. In order to maximise printing quality control, this building is an airtight system with few openings; an abstract wrapper that adapts to the interior spatial geometry. Some of these apertures are large gateways that can open occasionally to install new machinery on different floors. Others are simple variations for the aperture and transparency of a conventional metal skin that has no substructure. Inside, strict lighting control is necessary to ensure chromatic quality during the printing process. At certain points, the geometric system becomes three dimensional, converted into empty pillars that interconnect floors, stiffening the system against the horizontal stress and allowing controlled, selective light to enter the large, open plan workspaces.

This building is a mechanism for exhibiting and experimenting with the potential of the Diagonal 80 products: it is a space for pure production but also a sales space at the same time. Each construction item or finish is converted into a backing or application for the printed products: outdoor awnings, vinyls, prints on solids, partitions, ceilings or taut canvas light deflectors … The company constantly “refreshes” the building with its printed products, applying the new potential deriving from its technological innovations and adapting them to its sales strategy. Its self-produced output facilitates constant changes to the interior spatial system and the outdoor advertising systems. Once stamped, the printer reels become interior partitions, enclosures for courtyards or canvases for shade and advertisements.

The ends of the building consist of a system of rods, wires and taut canvas which in turn are a replicate and an extension of the structure and the interior spatial system: they have the same mission as a suit that clads the body of the building. Adapting to its geometry and skin, they change but do not hide its form and facilitate successive refits in order to update the image: low digital fashion with high technological quality that constantly transforms the building’s appearance.