Stepping up the hotel experience...

Low-impact tiny hotel suite that brings nature in

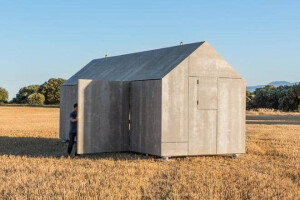

The Drop Box N-240 is a low-impact modular suite especially suitable for anyone who has an inherent yearning for nature but doesn’t want to cause a negative impact on the environment as a consequence of its stay in nature.

An alternative to traditional hotel accommodation by facilitating customers with a comfortable and sustainable stay in natural locations

The N-240 unit is part of the DROP box hotel suites Collection, which opens up a whole new world of possibilities for the hotel industry. This collection comprises transportable suites ready to be dropped into location as well as suites manufactured off-site, transported and quickly assembled... All these suites can be placed practically anywhere feasible and allowed.

A bed with panoramic views…

The suite is located in a touristic resort in Santa Maria de Palautordera, a village near Barcelona (Spain). It is a nice place with breathtaking views to the Montseny massif which forms part of the Montseny Natural Park. The Montseny Natural Park is in the Catalan pre-coastal mountain range. It is 25 km from the Mediterranean Sea and 50 km from Barcelona. Montseny massif is one of the outstanding protected areas in Catalonia, included in the World Network of Biosphere Reserves by the UNESCO.

The owner of the touristic property decided to increase the number of rooms, with an innovative and sustainable option. The N-240 floor plan features a living room, fully-equipped bathroom and queen bed platform with panoramic views to the forest… with a minimum occupation of the land.

The hanging terrace allows customers to fully immerse themselves into the forest

This 2,4-metre-wide module is a transportable suite that can simply be “dropped” into any setting with little or no impact on the surrounding environment. The DROP box N-240 suites are transported mounted via a trailer or a container ship. Available in three sizes, the largest units can accommodate either a couple or a family of four. The standard floor plan features a fully-equipped kitchen, bathroom with shower, queen bed platform with panoramic views, clothing storage shelves close to bed and an outdoor terrace.

The floor plan design can be customized in function of clients’ needs. In this project, the touristic property owner made some changes from the original design. For exmaple, the entrance door in cement-wood as the rest of the facade, instead of transparent glass. Also a bathtub instead the shower and didn’t include the kitchen, only a pre-installation for the future. The terrace as well as the tiny pod, have been installed elevated over a metallic structure due to the sloped terrain, and to minimize their impact upon the site.

Highly versatile and customisable hotel suite that provides to the guests a sustainable and comfortable room to stay in

The suite is framed with wood, a natural renewable and sustainable building material, and come with two different exterior finishes: natural wood cladding or composite panels made of cement and wood particles. The cement-wood panels are a low-maintenance material, non toxic, impermeable to water and do not degrade with the action of living organisms. There are several colors to choose from that present a non-homogeneous appearance, which is a product natural feature. All the hotel suites of the collection are highly versatile and customisable modules, providing to the guests a sustainable and comfortable room to stay in.

Opening up a whole new world of travelling possibilities...

Have a cup of morning coffee in the middle of the forest or sleep with a panormic view over the trees... The aim of this modular suite is to meet the growing demand for eco-tourism with customers that like traveling but don’t want to stay in common hotels and demand sustainable architecture mixed with comfort and design.

Innovation and Sustainability in Hospitality

Last December, this DROP box N-240 hotel suite was installed by the company Eurobungalow. After the arrival of the module in a trailer truck directly from the factory where was manufactured, the installation was completed in just 2 hours, despite the bad weather.

Material Used :

1. Floor structure: steel

2. Walls structure: wood frame construction

3. Roof structure: laminated wood beams

4. Thermal insulation: fibreglass

5. Facade: composite panels made of cement and wood particles (Viroc)

6. Roof: steel sheet

7. Floor: wood

8. Inner lining: tongue and groove wood planks