A shimmering silver garment attires the new North Rhine- Westphalia Textile Academy in Mönchengladbach – the tailoring and steel substructure of the textile envelope were calculated by formTL.

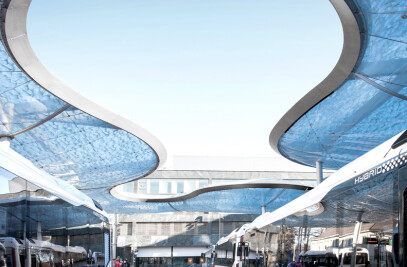

A tailor-made dress nestles around the newly constructed building of the North Rhine-Westphalia Textile Academy in Mönchengladbach. Even from a distance the shimmering silver garment gives the training school for the textile and clothing industry a strong presence on the campus of Lower Rhine College. It thus conveys the Academy’s learning content outwards, bringing to life the varied applications of textiles. At the same time, the transparent, seemingly moving membrane stands in strong contrast to the clear geometry of the three-storey cube that it envelopes. The building, built by slapa oberholz pszczulny | sop architekten, comprises a central atrium, teaching rooms and administrative offices along with an assembly hall. All window surfaces therefore lie hidden behind the membrane and only the entrance area appears uncovered, welcoming students and visitors with its generous glass façade.

While at first glance the textile façade appears to move around the cube in a uniform undulating movement, the picture becomes apparent upon closer examination as all the panels of the flowing garment differ in their respective tailoring. The required dynamic effect of the cover therefore had a significant effect on the method of construction. In addition to this, the architects wanted a supporting structure that was as slim and inconspicuous as possible. Both these parameters demanded precise planning and close coordination between all those involved in the project: the formTL engineers, responsible for cables, the steel substructure and membrane, thus worked hand in hand with the construction companies. The basis for the pretensioned façade was formed by formTL’s formfound membrane-cable structure developed with valley and ridge. As forming and load-bearing elements, the cables are spanned along the façade from top to bottom into the valley and ridge so that the cables share the loads caused by wind suction and pressure.

The approximately 2,100 m 2 textile envelope consisting of individual panels undulates around the cube, alternating in front of and behind the cables. Both the cables and the membrane are fixed to a steel structure made from horizontal steel arches. Shaped from square hollow sections, the different curve radii lend a particular dynamic to the wave-shaped cover. At the top, they are anchored to the building by steel brackets and steel struts, the connections having hinged connections. The inclinded bracings were necessary guide to the load in the concrete structure in order to guarantee the stability of the curtain wall façade skin. At the lower end, the load is transferred directly into the floor plate and roof of the underground garage. Apart from the variously shaped panels of fabric and the sometimes large distance between the cover and the concrete structure, the penetration of the insulation on the exterior of the building also proved to be a challenge in terms of statics.

To give the garment an appearance as light as possible and to largely conceal the structure, the garment was not attached directly to the horizontal steel arches. Weld-on, curved steel strips form the visual terminator and enable the fabric panels to clamp elegantly and almost invisibly with clamping plates in front of the load-bearing arches. The welds of the individual panels are also bearly visible they follow the vertically spanned valley and ridge cables. The cables have adjustable threaded fittings at their upper end with which the stiff fabric can be slightly readjusted. The fabric was structurally reinforced on the cut-outs membrane.

While during the day the building appears like a cloth-like form, even with a permeability of approximately 48 per cent, in the dark an exciting reverse effect manifests itself, for when the interior is illuminated, the variously sized window surfaces that are irregularly arranged across the façade come to light, creating a completely different and exciting look.

Material Used :

1. Steel: S355

2. Cables: Stainless steel spiral cables

3. Membrane: Verseidag B18909 GFM 4000-42 silver