Glass technology is more advanced than ever and many structures describe themselves as “all glass”, when most have steel elements or fixings as a main part of their structure.

The idea is to make a bridge made of glass with no metal fixings. As one of the principle qualities of glass is its high compressive strength, the proposal is to take sheets of glass and use gravity to apply sufficient pressure to compress them together to act as a beam.

1334 sheets of 12mm thick, low iron glass sheets are compressed together by active bearings that exert 800 tonnes of pressure from each end of the span. The active bearings are mechanisms that apply a constant load through the bridge deck, via a simple lever, loaded with a weight. The compressive force creates sufficient friction to hold the glass sheets together without mechanical fixings. The fail-safe mechanism is having two bearings, allowing one side to be locked off, whilst still applying sufficient force from the other. The deck is non-slip, as the wearing surface is highly textured.

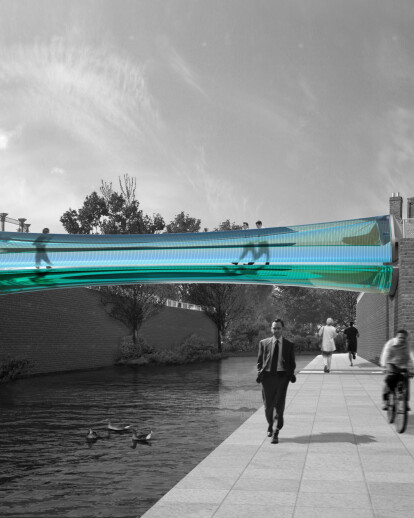

Usually bridges and buildings are lit externally, with light reflecting off their surfaces. The opportunity with the Glass Bridge is to light it internally thus performing as an optical device, with light transmitting through it. The Glass Bridge won the Bombay Sapphire Award 2002 and has since developed through to the end of the detail design stage (RIBA stage D).