The Lodsi Community Project is nestled in the Himalayan foothills, near Rishikesh, India. The area lacks basic infrastructure such as electrification, water, roads, etc. Most of this community migrates to cities for employment.

This project finished in the pandemic and has created a model of decentralised Industrialisation and an off grid sustainable project, that is net-zero on energy, water, and waste.This manufacturing facility provides employment to the local community. They walk to work and were spared dislocation and “catastrophic reverse migration”.

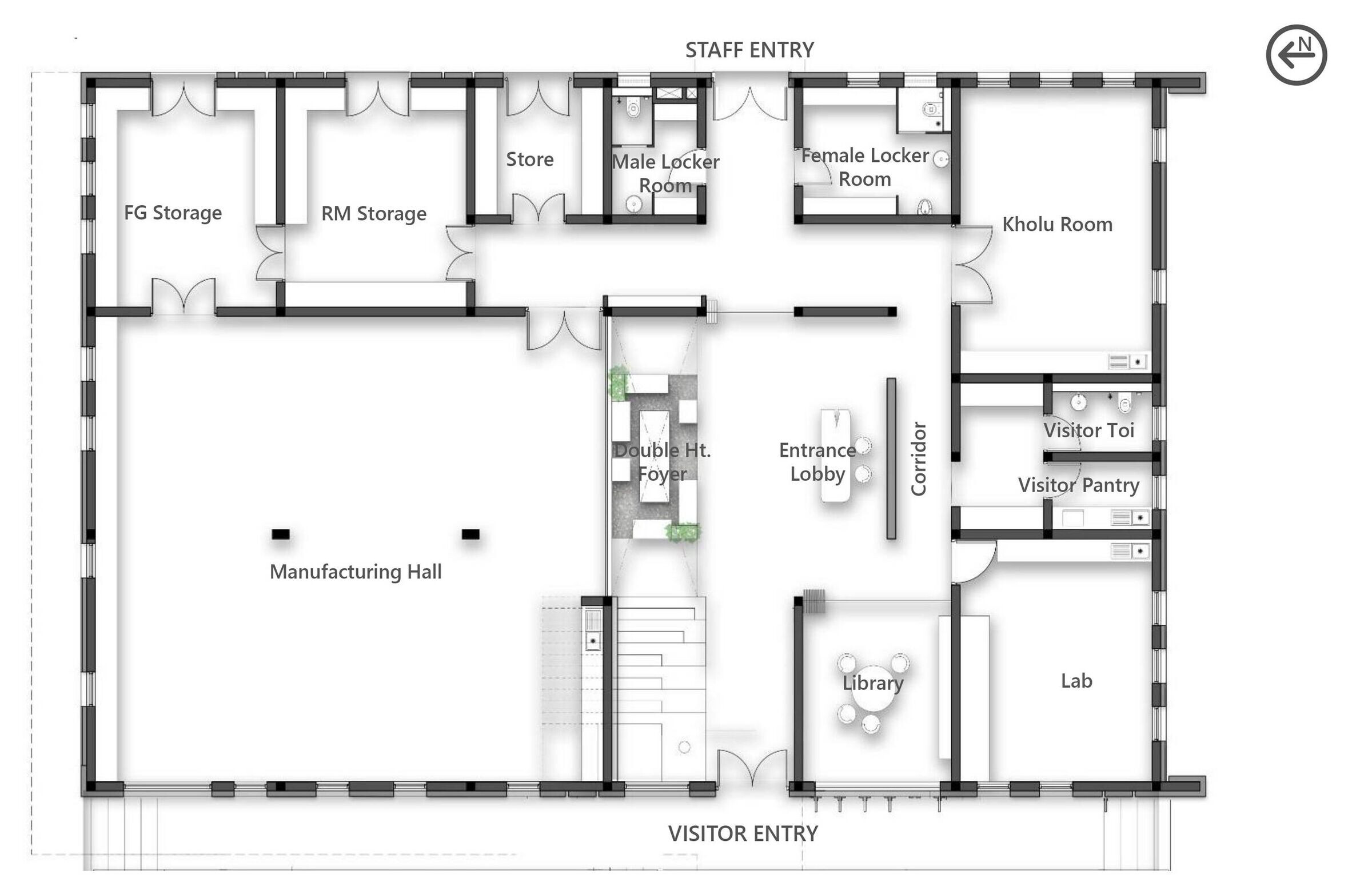

We used local materials and construction techniques and improvised these so that the “un-skilled hill people” could build it, much as they build their own homes. The built-form draws inspiration from the traditional Garhwali ‘kholi’ (house). A rectilinear volume oriented along the East-West axis has been planned with a central entry that divides the facility into two parts.

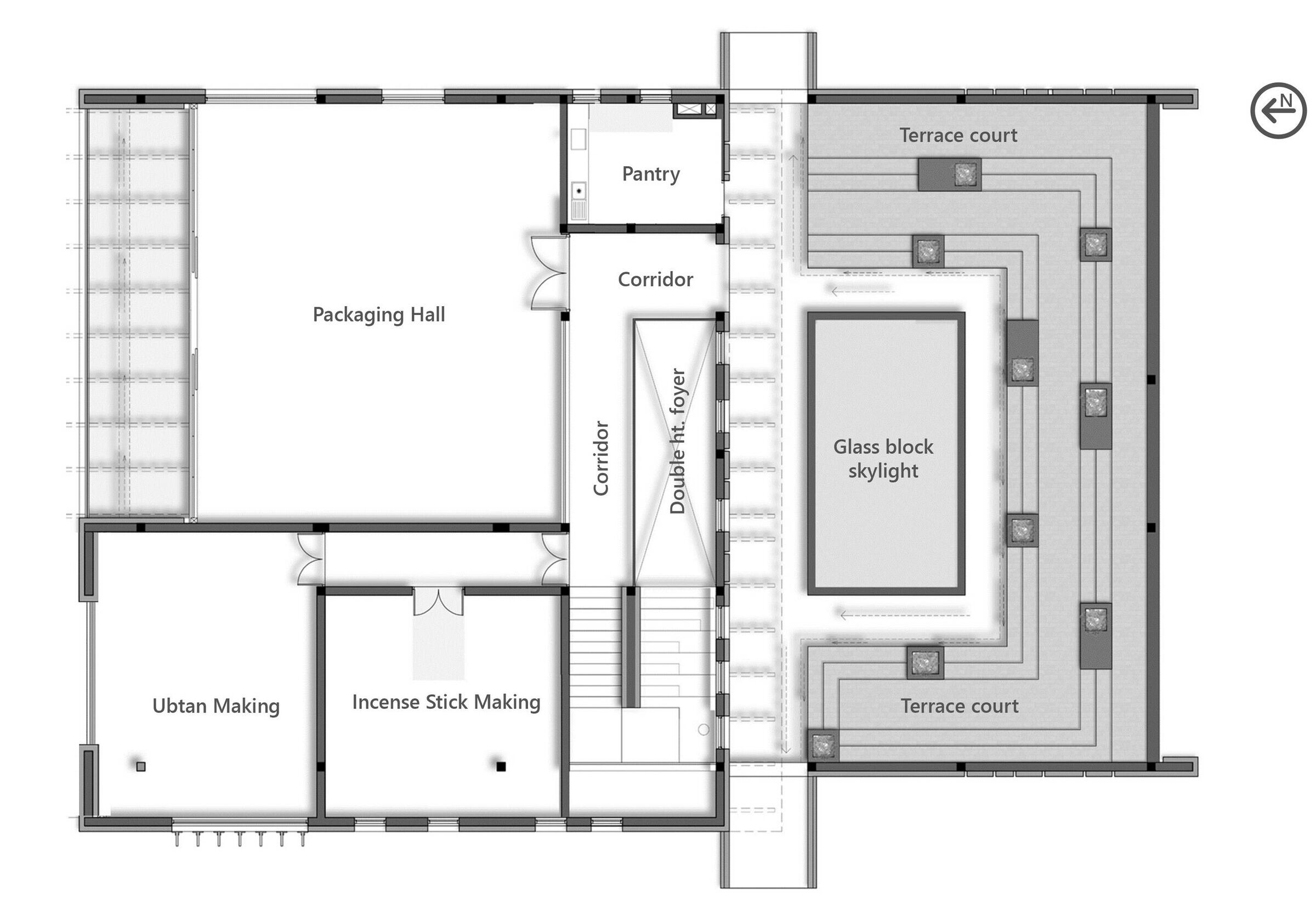

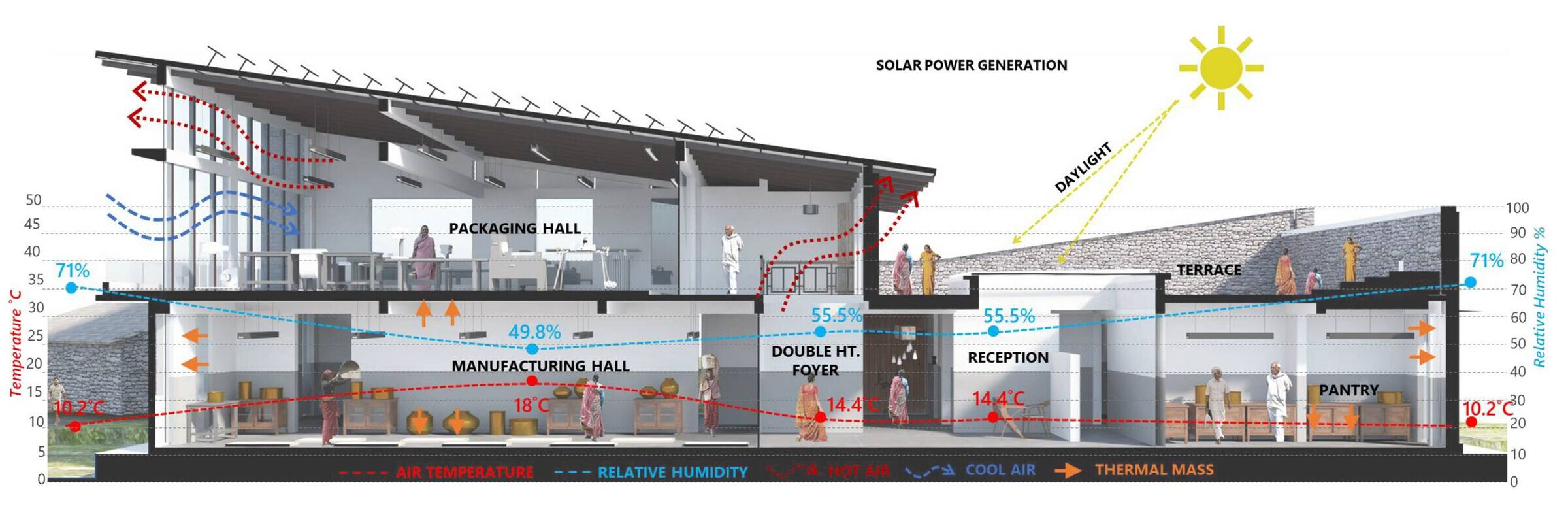

Functions that require a cooler environment such as herb grinding, packaging, and storage are located on the upper floor, whereas preparatory functions such as oil extraction with other high-internal heat-gain processes are on the lower floor. The North-South oriented butterfly roof form allows large openable windows that allow the prevailing North-East and South-East winds for ventilation, with 80% naturally day-lit spaces and unobstructed views of the valley. The high-volume of space with operable clerestory windows enforces Bernoulli’s principle and moderates indoor temperatures. A central light-well forms a Multi-purposecommunal space.

This also doubles over as mother and child wellness camps and for students post school.Passive design strategies and indigenous construction techniques resulted in a strong architectural expression, one that contextually blends in and builds community pride. Façade shading, window-to-wall ratio and building materials were optimised to ensure a high-thermal mass façade resulting in an energy-efficient building envelope with an EPI of 38kWh/m2/year. A solar roof generating 55kWp offsets the facility’s requirements and generates surplus to supply back to the grid, hence ‘Energy+’.

A site-specific rainwater collection, storage tank and treatment system, an effluent treatment plant offsets the water requirements. Waste-materials at site have been repurposed and used, e.g., reclaimed wooden rafter as light fixtures, waste purlin sections as tube light holders, stone chisels as door handles, re-bar as washbasin pedestal, and others. Any organic by-product is reused or composted. This project is net-zero on energy, water, and waste.

The planning incorporated the existing ‘gaushala’(Cow Shed) for production of milk-based products. 65 villagers built the project, the building supports 45% of the village households directly and the entire village indirectly. The use of vernacular materials, techniques, and village labour forms the ethos of the facility, making it “A Project for the locals, built by the locals and for the employment of the locals.”

The Lodsi Community Project addresses socio-cultural and economical sustainability. It is an example for decentralised development in the post-pandemic world. This project stayed functional through most of the pandemic, and we believe this is the exemplar for future growth across India.

Material Used:

1. Facade cladding- Local stone

2. Flooring- Tiles, Concrete Paver Blocks

3. Doors- Local Wood

4. Windows- Metal

5. Roofing- Metal Roof

6. Interior lighting- Repurposed Metal & Wood sections

7. Interior furniture- Repurposed Wooden Logs