The Microsatellite Science & Technology Centre (MSTC) for the University of Toronto Institute for Aerospace Studies (UTIAS) is a networking hub for Canadian researchers developing nanotechnology and microsatellites for use in space. The building’s lab area accommodates the assembly and testing of microsatellites while the office space supports the design, development and the monitoring of microsatellites after their mission launches.

Background

A unique building type in Canada, the MSTC sought an Industrial Aerospace image that would address the creative design, manufacturing and management processes of putting micro-satellites into space. Kearns Mancini responded to UTIAS’ call by designing a facility that served the needs of the researchers, while embodying the ambitious nature of space exploration.

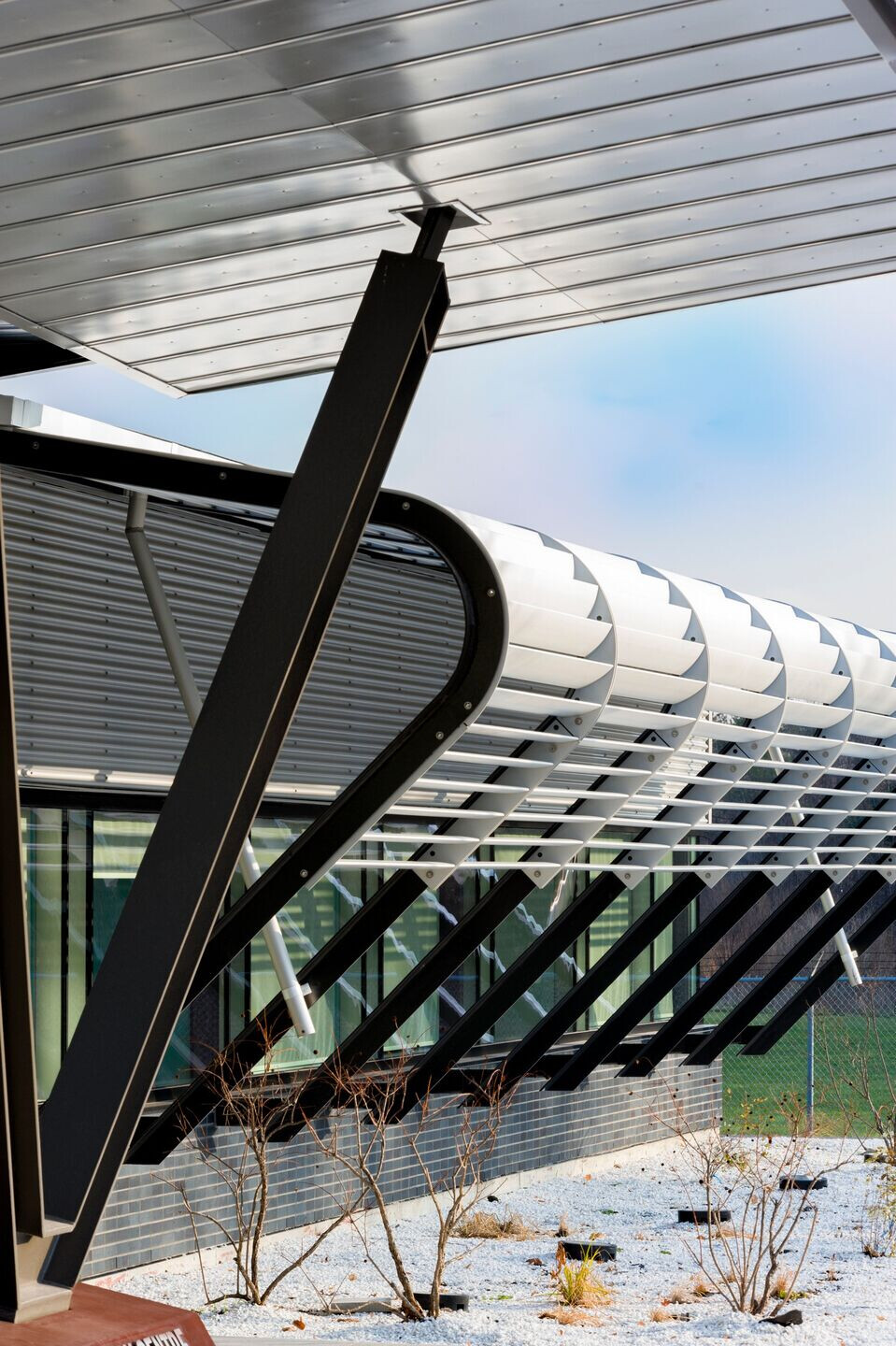

The building siting replaced an oversized parking and loading area adjacent to the original structure while leaving the site’s existing green spaces intact. The centre operates using a Passive Energy strategy; daylight and solar gain is maximized during the winter and vice versa during the summer, by using strategic roof overhangs and shading devices.

These design strategies also serve to enhance the quality of the research and meeting areas, providing for a pleasant environment in which to collaborate and to undertake research. The spaces created accommodate the levels of precision and control that is required of such a facility. Strategic to this was Kearns Mancini’s ability to provide this level of detail on a very tight budget.

The Process

As the University of Toronto had been facilitated by Knowledge Infrastructure Program funding, the building’s design and construction process was required to meet a federally-mandated project delivery timeline, which Kearns Mancini was aptly suited to responding to.

Service elements such as the 7.5m tall, 6,000 litre liquid nitrogen tank are judiciously placed to mediate between the older UTIAS building and the new MSTC. The buffer space between the existing UTIAS building and the new free-standing MSTC addition minimizes the cost of joining the two disparate structures.

Kearns Mancini ensured careful and considerate coordination of the client’s equipment, meeting on many occasions to determine what exactly the client’s needs were, in order to develop the most adaptive spaces possible. This process included the installation coordination of a vacuum and liquid nitrogen storage tank, with drawings developed to a 10th of a millimeter in accuracy, in order to ensure that the installation of these complex items would not create undue complications during the construction process. These strategies ultimately resulted in highly tailored, functional spaces.

The Results

Kearns Mancini’s consistently high level of engagement on the MSTC project enabled the coordination of complex scientific experiment equipment to proceed with ease.

UTIAS appreciated the sympathetic precision of the building’s design and execution, noting that the spaces served their needs, while providing for a pleasant, enjoyable work environment.

The inclusion of skylights along the roof, contrasted against splashes of colour, serves to bring a dynamism and vibrance not ordinarily seen in such research facilities. A curvilinear roof was developed to subtly express the aerospace research function of the building, which included sun shading devices to control the south and west sun angles. The scale of the canopy draws no undue attention to the building, and yet serves as an effective beacon to the facility.

The result of a consistently collaborative process, the MSTC fulfills an iconographic function, associating with the University’s aerospace research function, while also providing for the client a series of highly functional and adaptive workspaces that delight with natural light, colour and transparency. Ultimately, the building’s singular form reflects the nature of satellites – a simple form housing sophisticated and precise instruments.

Team:

Architect: Kearns Mancini

Mechanical and Electrical: MCW Cosultants Ltd.

Structural: RJC Engineers

Site Services: A.M. CanderasAssociates Inc.

Photography: Doublespace Photography

Project Team: Jonathan Kearns, Peter Ng, Keith Button