People’s Pavilion won the Frame Awards 2018 in category Sustainable Design, The Dutch Design Awards 2018 in the category Habitat, and the ARC18 Innovation Award. People’s Pavilion is nominated for the New Material Award and the ARC18 innovation award. People’s Pavilion is published in the Dutch Yearbook of Architecture 2017/2018.

From 21 to 29 October the Dutch Design Week (DDW) - the largest and most important design event in Northern Europe - will take place in Eindhoven (NL). This year DDW and Design City Eindhoven launch the first edition of the World Design Event (WDE), which provides a platform for future makers from all over the world. And at the heart of Dutch Design Week is the People's Pavilion, a design of bureau SLA & Overtreders W.

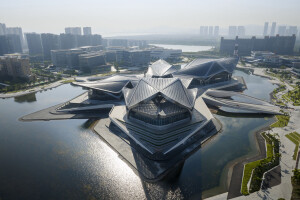

The pavilion is a design statement of the new circular economy, a 100% circular building where no building materials are lost in construction. The designers of the bureau SLA and Overtreders W have accomplished this with a radical new approach: all of the materials needed to make the 250 m2 building are borrowed. Not only materials from traditional suppliers and producers, but also from Eindhoven residents themselves. And to be clear, it’s not 70% or 80% or even 95%, but 100% of the materials: concrete and wooden beams, lighting, facade elements, glass roof, recycled plastic cladding, even the Pavilion’s glass roof, all of which will be returned completely unharmed - with one special exception - to the owners following the DDW. The exception? The striking colored tiles that make up the Pavilion’s upper facade, made from plastic household waste materials collected by Eindhoven residents, which will be distributed among those very residents at the end of DDW.

100% borrowed means a construction site without screws, glue, drills or saws. This, in turn, leads to a new design language: the People's Pavilion reveals a new future for sustainable building: a powerful design with new collaborations and intelligent construction methods.

Program The People's Pavilion is the main pavilion of the World Design Event. It is used as a meeting place and hang-out for visitors and serves as a venue for music and theater. The Pavilion is programmed for two weeks during the days and evenings with events like the Age of Wonderland, the award ceremony for the national Who Cares competition, a TEDx try-out, the Making of Your World readings, and a Climate Action debate. The Pavilion can accommodate 200 seated or 600 people standing and is open to all: one doesn’t need a ticket to enter.

Design outline. The base for the People's Pavilion is a construction of 12 concrete foundation piles and 19 wooden frames, designed in collaboration with Arup. The frames consist of unplaned wooden beams of standard dimensions, held together with steel straps. Concrete piles and frames are connected with 350 tensioning straps, creating an eight meter high primary structure for the 250 m2 building. The glass roof is made using a system that is commonly employed in the greenhouse industry. The Pavilion’s upper facade consists of colored plastic tiles, made of recycled plastic household waste, collected largely by Eindhoven inhabitants. The glass facade on the ground floor is a leftover from a refurbishment of BOL.com's headquarters and will be used for a new office space after the DDW. The podium consists of borrowed concrete slabs. The lighting, heating, bar and other interior elements of the People's Pavilion are also borrowed.