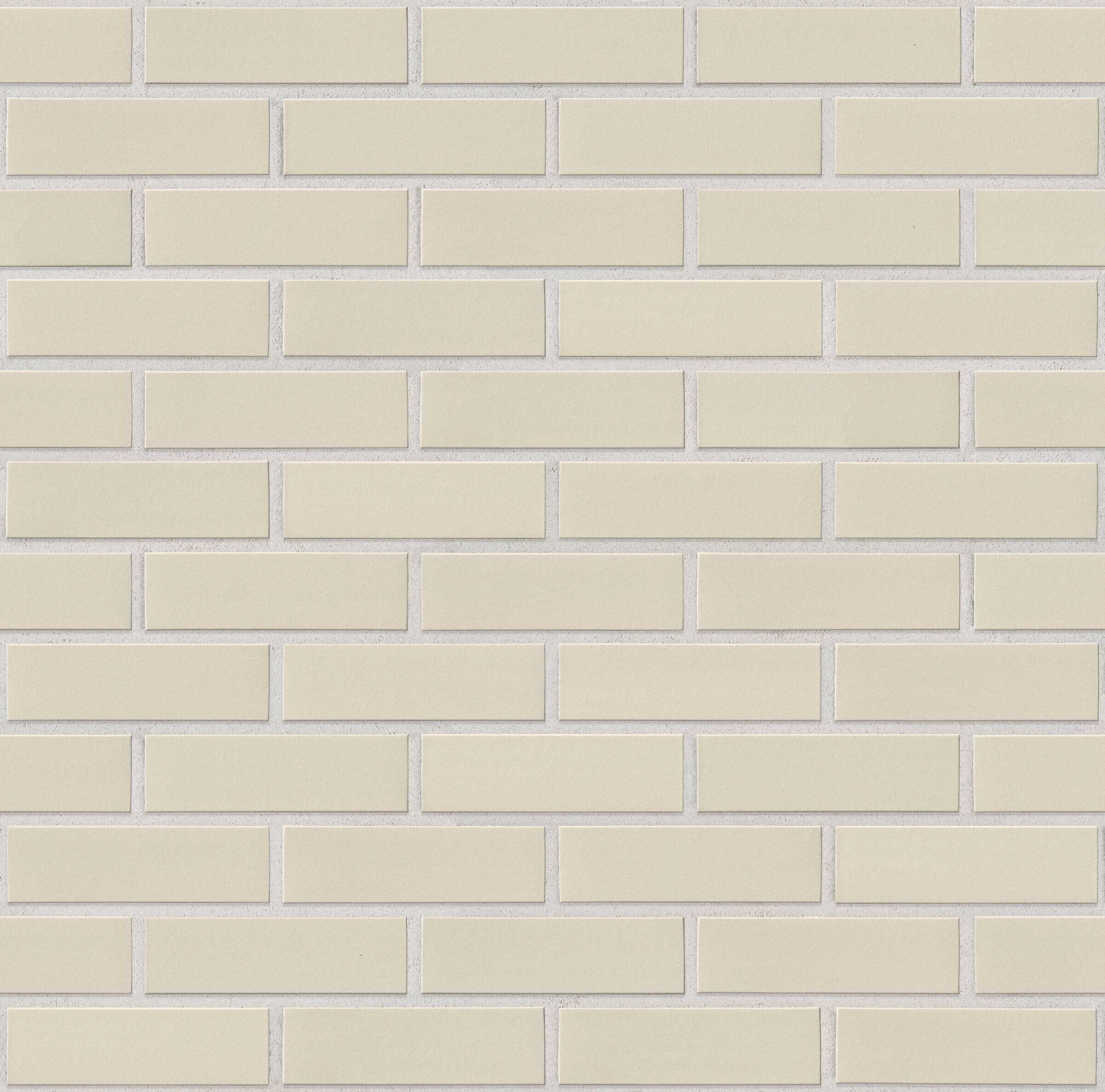

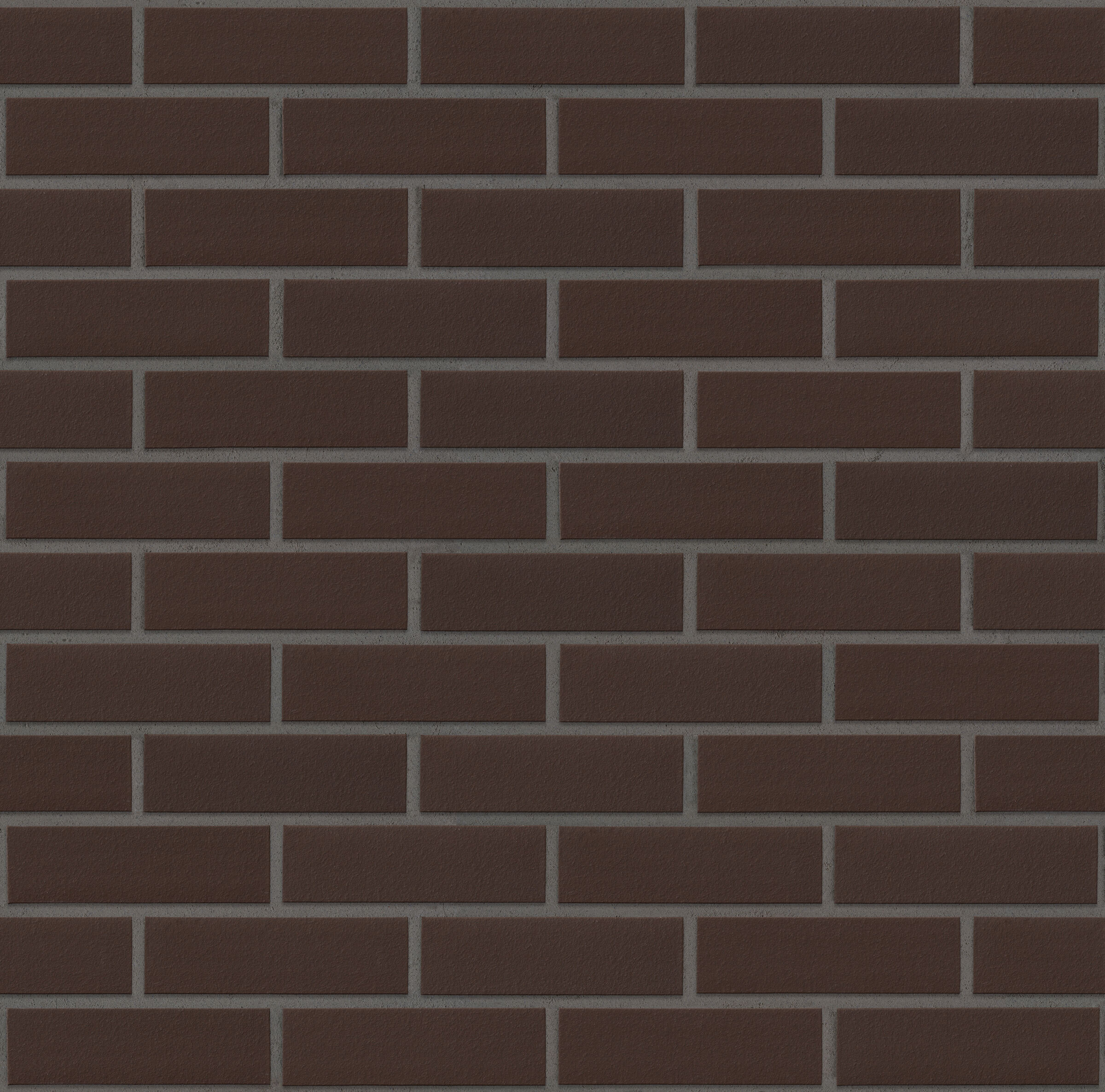

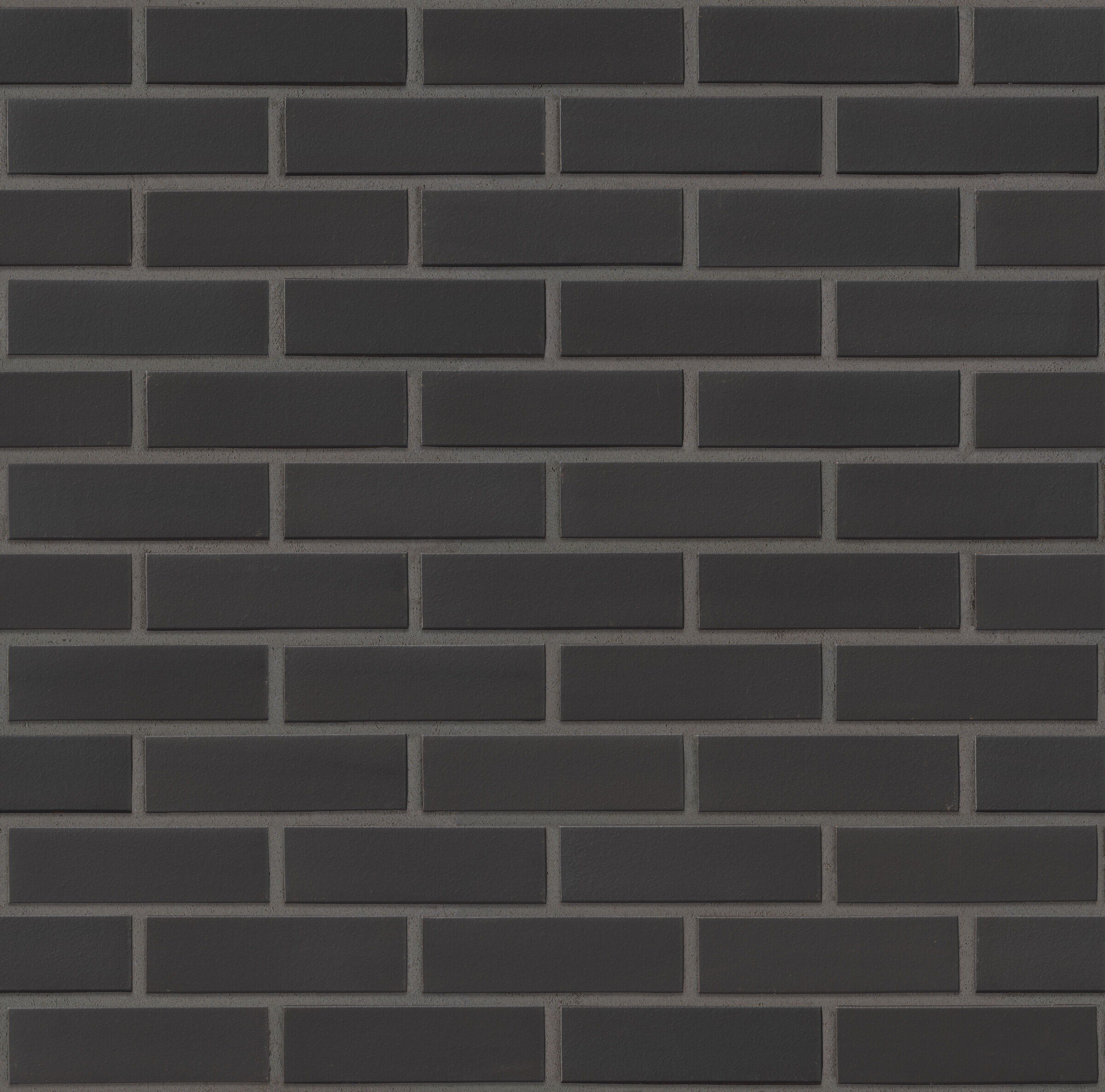

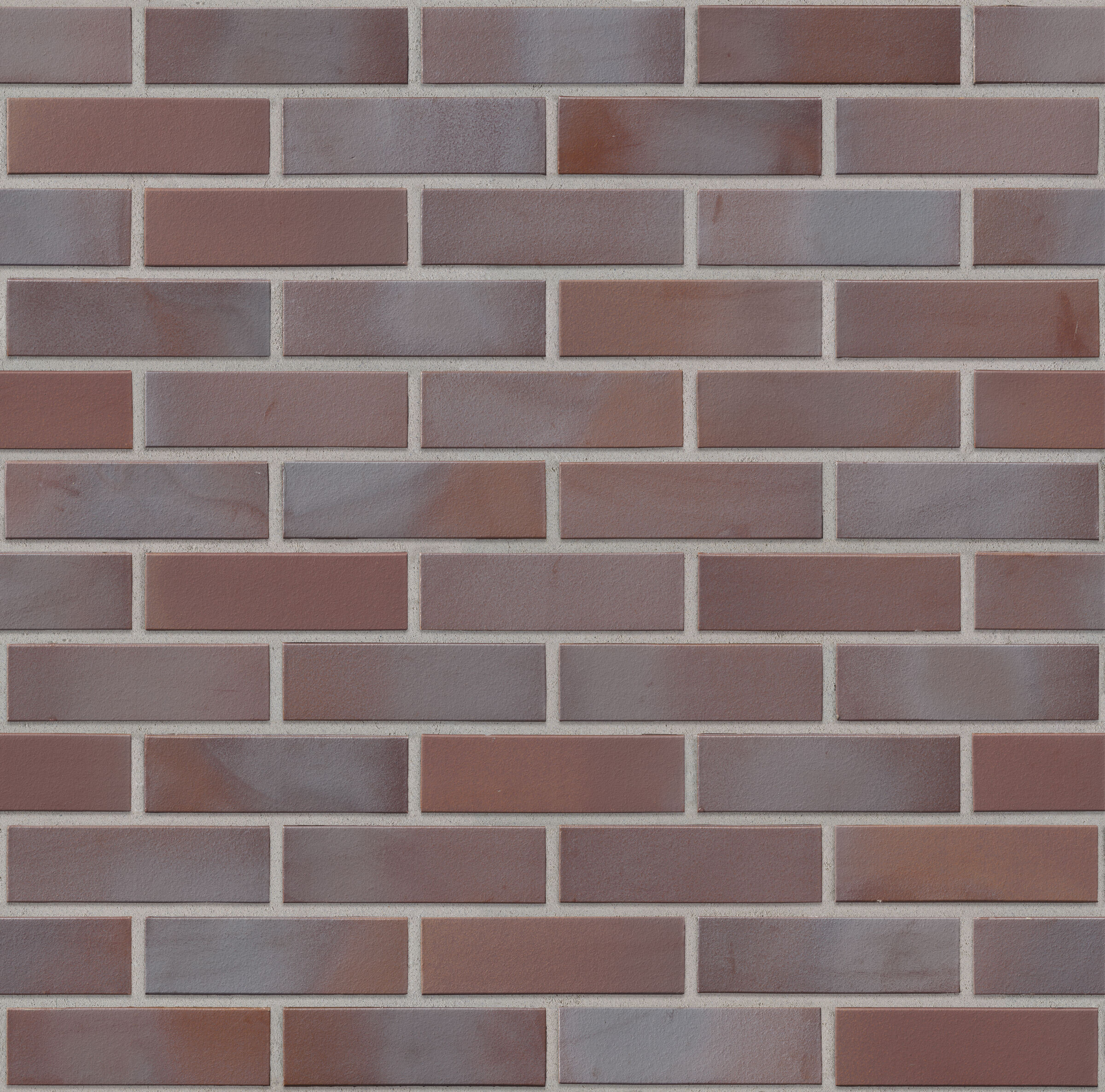

24 beautiful color tones, numerous formats and glazed or unglazed surfaces give architects and designers a nearly unlimited choice of options. Each facade quite easily becomes unmistakeable.

A versatile and durable solution

Whether used in residential, commercial, or institutional projects, Stroher's Keravette brick facing product offers architects, builders, and designers a versatile and durable solution for enhancing the aesthetics and longevity of building exteriors and interiors. With its high-quality materials, meticulous production process, and straightforward installation, Keravette brick facing exemplifies Stroher's commitment to innovation in clay brick manufacturing.

Material thickness

The material thickness of 8 and 11 mm means this classic among clinker brick slips is not only light but, thanks to the especially high firing temperature, it is also extremely robust and price friendly.

Production process

Stroher's production process for Keravette brick facing begins with the careful selection of high-quality natural clay sourced from local deposits. This clay is then meticulously processed and refined to remove impurities and ensure uniformity in texture and composition. Once prepared, the clay is shaped into bricks using state-of-the-art molding techniques, allowing for precise control over dimensions and surface finish. Stroher offers a variety of texture options within the Keravette product line, ranging from smooth surfaces to subtly textured finishes, catering to diverse design preferences.

After molding, the bricks undergo a thorough drying process to remove excess moisture, ensuring optimal strength and stability. They are then fired in kilns at high temperatures, a crucial step that enhances the bricks' durability, frost resistance, and colorfastness. Throughout the production process, Stroher adheres to rigorous quality control measures to maintain consistency and excellence in every batch of Keravette brick facing.

A guide to clinker brick installation

Before applying the slips, the visible dimensions of the window and door lintels need to be worked out. It is rare that the reveal and lintel measurements correspond to the standard brick slip sizes. This is why the joints between the brick slips need to be adjusted. The overview dimensions calculated are then also transferred to the outside corners.

After working out the heights at the corners of the walls, the angles at the outer corners are applied using the floating-buttering method. “Floating” describes the application of the adhesive using a notched trowel in medium-bed adhesive. “Buttering” means coating the back of the brick slip with adhesive using a spatula or trowel. Before the surface is worked, the connections between stretches of masonry first need to be determined. In most cases, ‘disordered’ joining is recommended in which five head ends per square meter are included. The head visually forms the front end of an entire brick and in the case of clinker slips is cut from the surface using a tile cutter or a radial cutter.

After applying the clinker slips and after a corresponding drying time (see the adhesive manufacturer‘s instructions), a start can be made on grouting. Clinker slips with smooth surfaces can be processed by the slurry method. There are a number of grouts on the market but some have plastic and pigment additives. For this reason, installers should always consult the mortar manufacturer regarding suitability before choosing the grout. All rough, patinated and textured surfaces are grouted with a conventional pointing trowel and a metal float.

150 years of experience

Ströher was founded in 1880 in Dillenburg, Germany, and has established itself as a leading manufacturer of high-quality clay facade bricks renowned for their durability, aesthetic appeal, and technical performance.

With a heritage rooted in traditional craftsmanship, Stroher has continuously evolved to meet the demands of modern architecture while maintaining its commitment to quality and innovation. The company's extensive product range encompasses a variety of clay facade bricks, including smooth, textured, and glazed finishes, as well as specialized shapes and sizes to accommodate diverse design requirements.

Stroher's clay facade bricks are recognized for their elegance, versatility, and sustainability. Made from natural clay sourced from local deposits, these bricks undergo meticulous manufacturing processes to ensure superior strength, weather resistance, and colorfastness. Architects, designers, and builders worldwide trust Stroher's products to deliver exceptional performance and aesthetic value, making them a preferred choice for prestigious projects ranging from residential homes to commercial developments and public spaces.

Reference projects

Designed by Aicher Architekten, the form of the monolithic building with his sharp edged facades produces a strong dynamic, which stands in a positive tradition of the booming and flexible architectural language of Dornbirn. The architects opted for a brick slip facade on a normal thermal insulation composite system to optimize costs. The building has been designed to stand out. According to the architects: “Stumbling across a large office complex clad in clinker brick slips in the midst of an Austrian chocolate box setting of timber and plaster facades will be sure to make you do a double take.”

The project, designed by Kjellander Sjöberg, is a part of a new urban district in Växjö, Sweden being developed along the railway connecting the city center to the lake Norra Bergundasjön. The L- shaped building is the first phase and the cornerstone of the city block, offering mixed forms of tenure around a spacious, shared courtyard. The design and configuration are strongly linked to the construction process. The variation in the brick façade is rationally achieved by using more joints than façade elements and by combining four sections of different types of tile patterns. The overall design thus resembles a textile pattern or a crocheted tablecloth. Entrances, windows and roofs are accentuated by copper-coloured metal sheets, adding warmer tones. The building is designed to achieve LEED Platinum certificate and Skanska’s top level environmental classification.

The new swimming center of Brescia

Camillo Botticini Architect's design for the new swimming center in Brescia is characterized by simplicity and functionality, with a focus on practicality and sustainability. The brick facade of the building adds a touch of warmth and texture, integrating harmoniously with the surrounding urban context. Through careful attention to detail and material selection, the architect has created a timeless yet contemporary aesthetic that complements the facility's purpose while respecting its environment. The clean lines and understated elegance of the design ensure the swimming center of Brescia serves as a welcoming and inviting space for athletes and visitors alike.