Resin flooring

All About Resin Flooring

Resin flooring is a tough and durable plastic surface produced with a mixture of constituents in a controlled chemical reaction. The result is a durable product that works best in heavy use environments. In other words, resin floors are made by the chemical reaction between polymers that create a chemical bond with the substrate to produce a solid floor surface. Resin floors are extremely durable, safe and a comfortable flooring solution for many applications. Also, these type of floors are resistant to chemicals, extremely and highly flexible in terms of design. The easy to clean, damage resistant features provides offer an attractive, customizable look.

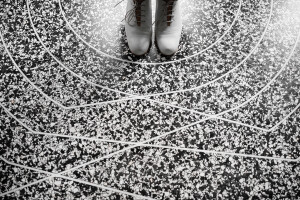

Resin flooring is a top choice for contemporary homes. It has high compressive strength and ability to bear more weight than other types of floor. Also, it has unique sealer that prevents the surface from water and moisture damage. The surface prevents dirt from being trapped and makes it easy for cleaning. This surface also keeps bacteria away, which is needed in high care environments. Resin floors are ideal for the type hygienic floor surface required in in schools, hospitals, kitchens and food factories etc. It provides a wide range of benefits for industrial and commercial industries. Due to their great design and flexibility, resin floors offer a high degree of slip resistance and thus perfectly suit wet environments such as swimming pools and kitchens.

Resin floors exist in a wide range of designs and finishes from decorative flakes to epoxy coatings, Poly Methyl Methacrylate and Polyurethane. PMMA is a thermoplastic resin highly suited for industrial needs. Polyurethane resin flooring provides excellent resistance to impact, abrasion and other chemicals. Epoxy is most commonly used in industrial resin flooring.

However, maintenance is required for resin flooring to ensure a completely safe working environment for all operatives. Damage can be caused by wear and tear, abrasion or chemical exposure etc. Floor repairs can be done with cement or epoxy resin based mortars to harden and cure the moisture content for the resin flooring system. Holes and cracks can be patched and filled with high bond kits. Polyurethane flooring is tough to work with whereas epoxy takes time to fully cure. As PMMA resin flooring is fully cured in minimum time, it is an ideal choice.

Resin flooring is one of the best flooring options to enhance the aesthetic value of a space. It is available in various designs and customizations. Also, it is one of the most hygienic and chemically resistant flooring solution available in the market.

Needless to say, resin flooring is an optimum choice for many industries as these floors are well known for durability, longevity, hygiene etc. However, selecting the best resin flooring should be based on the usage and requirement. These flexible floors are ideal for commercial and industrial environments as well as schools, hospitals, kitchens and food factories etc. The seamless surface stops dirt from being trapped, allowing for easy cleaning and even steam cleaning.