In Sandefjord, carpenter Dag Olsen and his colleagues at Bygg og Maskin AS are busy mounting STENI façade panels on the new ice rink at the Bugårdsparken recreation centre. He estimates that two people can install around 70 square metres of façade panels each day.

“I think this is the fastest way to install a façade. The panels are pre-drilled, so once we get them screwed in place, the wall is basically finished,” says Olsen. “This project uses a combination of STENI Nature, STENI Colour and STENI Vision. The panels are numbered and stacked in the correct order on the pallet in accordance with the specific design. This is a system that I can recommend,” says Olsen, who is in the process of mounting panels to create the image of an ice skater on the wall.

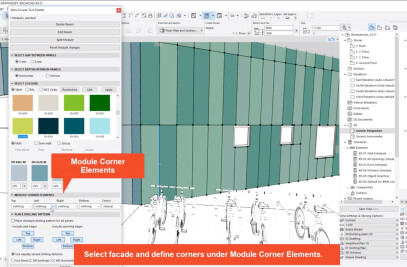

Steni’s unique production technology ensures that customer solutions are installed faster – and at a lower cost.

“Cutting and drilling equipment is an integral part of our production line. It allows us to work on the panels continuously throughout the manufacturing process,” says Tom Kristian Hvaal, Head of Technical Support (TSD) at STENI.

Planning

“We often find a lack of space on building sites. There needs to be room for lorries and other heavy machinery, as well as all the different construction materials required for the job. From a logistical point of view, it is extremely important to have all the pallets organised in the right order at the construction site,” says Hvaal. “Good planning allows STENI to pack the panels and mark the pallets according to what order they are going to be mounted onto the façades. The panels can also be sorted so that they are in the right order for the installers.

“We can deliver finished, optimised panels to the site. Many people do not take the entire cost profile of a product into account in their cost analysis. Things like installation time and the cost of scaffolding are factors that we can clarify to our customers in advance,” he says.

Pre-drilling is cost-effective

STENI’s unique production line allows for multiple simultaneous operations. This means that there is no need to move the panels to a new machine for cutting and pre-drilling purposes. This function is built in to the line. Pre-drilling lets you screw the panels straight onto the wall without having to drill holes or use self-tapping screws. With custom shapes and sizes, you don’t have to cut the panels on the construction site and use resources to dispose of off-cuts and residual waste.

“It’s very time-saving,” says Hvaal.

Pre-drilling enables you to screw the panels straight onto the wall without having to drill holes or use self-tapping screws.

This project uses a combination of STENI Nature, STENI Colour and STENI Vision.