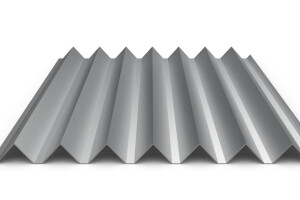

For the new building of the "Koninklijke Munt in Houten" in english Royal Dutch Mint, Architectenbureau Wilma-Watiau (BE) has opted for Isis point profiles from ArcelorMittal Construction Tiel (Specials department) in the color gold.

A good design of the facade can give an office, school, hospital or other project an appearance that makes the building unique, in keeping with the time and the house style of the owner and distinctive from the rest. ArcelorMittal Construction, the world's largest steel producer, offers a very wide choice of architectural and technical solutions for facades, roofs, floors and ceilings made of metal. The 'Specials' department, in close consultation with the architect and client, develops unique facade solutions that give a building an extra dimension, also for the new building of the Royal Mint in Houten, for which they combined an existing profile with a unique coating.

As the world's largest steel producer, ArcelorMittal has everything in house for steel production: from the extraction of iron ore to the production and delivery of semi-finished and finished products. ArcelorMittal Construction offers the architect, project developer or client various roof or facade solutions, such as single-walled profiles, insulated sandwich panels, steel plate concrete floor profiles and associated typesetting. “ArcelorMittal has been synonymous with innovation for more than 100 years and six years ago we decided to set up the new 'Specials' division in the Netherlands, which, as the name suggests, focuses on special developments,” says Levi Kleinjan with ultimate responsibility. “Architects, assembly companies and also builders increasingly have wishes and requirements that cannot be met with a standard solution. These "Specials" often relate to the facade or interior of a building. For example, new coatings and colors are continuously being developed and there is also a regular demand for unique profiles. We have a team of driven and experienced employees, our own R&D department and an extensive machine park in production facilities in the Netherlands (Tiel) and France. ”

From idea to approved solution, from production to assembly supervision

Each new development is worked out specifically for a specific project. The ArcelorMittal team listens to the architect and translates the ideas into an innovative solution with the aim of giving the building architectural added value. “We start from a sketch or idea and supplement it with materials, shapes, colors and finishes. This thinking process always takes place together with the architects, because we can then immediately make it clear to them whether their creative thoughts can actually be realized or not, ”Kleinjan explains the method. “In the next phase, the project is fully drawn up with us. In some cases we can fall back on elements that we have already realized for a particular application in the past, but in many cases we have to develop the solution from scratch. Ultimately, we arrive at test models that are presented to the architects and clients. After the model has been finally approved, we can prepare and plan the production and look for an assembly company that can realize the installation with our support, just as we originally conceived it. ”

Combine an existing profile with a unique coating

When architectural firm Wastiau started designing the new building for the Koninklijke Munt in Houten, they also contacted the "Specials" department of Arcelormittal Construction Tiel. In the past, both partners had already realized projects together before, and there was also a previous collaboration with Heylen Warehouses. “It soon became clear that for this project we could use a profile that we had already developed for another building in the past. In order to meet the requirements in terms of, among other things, the color and gloss level of the finish, a unique coating was required, ”says Levi Kleinjan. “The development phase of a project often takes one to one and a half years. In the best case, we already have a final model in four months, but sometimes it can take up to two years. The design of the special facade profile for the new building of the Royal Mint took just under a year. Architect and client were convinced quite quickly. Belfaconstruct turned out to be the ideal partner to realize the project. They themselves took a lot of initiative and ensured a flawless installation. Moreover, they asked us to jointly develop the underlying construction for the facade elements. ”