Made in Bourgbarré

In this Breton village, watched over by its belfry and our factory’s towers, our employees’ enthusiasm and hard work have allowed the Panaget range to flourish. We have been growing constantly since 1929, transforming our craftsmanship into proven manufacturing expertise that is recognized throughout the industry.

All this is achieved with two plants, 150 employees, 100% French oak, and integrated product development and design. Panaget is a true success story. But instead of resting on our laurels, we strive for continuous innovation on a daily basis, both in France and export markets. We do everything we can to offer the finest French-made quality and style. The possibilities of the new technology we’ve developed are almost infinite ...

Enabling us to continually build on our know-how and experience.

The Bourgbarré glueing line is supplied by a mechanized gantry. It is managed by Stéphane, who uses his 30 years’ experience to ensure that it runs smoothly at all times. He monitors and maintains the equipment that helps us to provide such a high-quality service, and his detailed knowledge of the line makes him an essential member of the Panaget team.

We use centuries-old techniques, and we have a genuine passion for what we do.

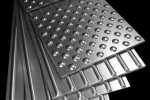

Orféo, , a three-ply engineered flooring in which the strips are made up of glued layers on a support medium, is also mass produced. The three components – wear layer, core and counterbalance – are glued together in a high-frequency press. The flooring is assembled on an automated production line, supervised by Nadine, who has 27 years’ experience at the Bourgbarré factory. Her job is to monitor and adjust the line to reflect changing production needs, while ensuring that safety requirements are met.

Origine: a combination of passion and technology.

It is here, supervised by Pascal (a trimmer at Panaget for 19 years) that the Origine line’s uniqueness and originality come to the fore – thanks to features like industrially aged chamfers and the natural flaws of the wood, which becomes more beautiful over time. Applying traditional craftsmanship on an industrial scale is what Panaget is all about.

People and technology

Just as the robots at our Redon site must operate at 100% productivity, so we must continue adapting to changes in the marketplace. Nicolas, a trimmer with seven years’ experience at Redon, is also responsible for the day-to-day maintenance of the machines, which includes carrying out inspections, replacing defective parts and locating faults. He ensures that the production lines operate optimally and meet the highest possible standards of quality and productivity. Whatever needs doing, he’s the man for the job!

Quality and expertise at every stage of the supply chain.

Women make up over half of Panaget’s workforce, combining a passion for wood’s refined nature with proven technical ability. Tatania, a trimmer who has been at the company for eight years, heads the Redon glueing line. This is a recent addition to our operations, with several automated processes. Tatania’s professionalism makes her a valuable asset to the business. Redon produces a distinct range – each packet contains a mix of strips of different lengths, from 400 to 2,000 mm. Combining different size strips is a traditional French practice, but Panaget does it on an industrial scale. We revisit classic designs, bringing them up to date to meet the needs of the 21st century,

And blending age-old crafts with the latest technology.

Automated machinery like ours requires constant supervision. Yves, a senior workshop technician who has been with us for 25 years, brings his valuable experience to the production process by diagnosing and finding solutions to problems. His technical skills, and specialist preventive and curative maintenance expertise, ensure that our machinery operates efficiently, day after day.

Designers draw on wide-ranging know-how.

Sophie Briand, a designer at Panaget for the past three years, and Rémy, our head of methodology, who has been with us for 25 years, combine their talents to develop and showcase the innovations of tomorrow. Each new project and product is the fruit of teamwork and detailed analysis, as we move from the idea to the design, testing and production phases. One of our greatest strengths is our ability to evolve and adapt. And design plays an integral role in Panaget’s development. We are committed to creating original products of impeccable taste, with an unmistakably French touch.

PANAGET Product

Café crème PANAGET

The Panaget house enriches its collection of 100% French oak floors with the new Café crème finish.This new colour is a beautiful altern...

Other Floors and Stairs Products

Member Promotion

Affrescati Ceramiche Refin S.p.A.

Traces of History

Places enlivened by creative expressions, collective memories, experienced historical periods: gestures and testimonies that take s...

Our Products are Used in Projects by

Projects with Products from PANAGET

PANAGET Offices

Floors and Stairs Brands

Is this your brand and would you like to remove content from other manufacturers on your brand page? Contact Archello