Kalwall® is a US-based company that has been producing insulated translucent wall panel systems for 65 years. Kalwall has manufactured components for epoch-making buildings that range from the US Pavilion designed for the 1958 World's Fair by Edward Durrell Stone, to the residential House VI by the architect Peter Eisenman and the recent CopenHill project for an industrial-cum-sports activities building in Copenhagen by Bjarke Ingels Group (BIG).

Kalwall's composite structural sandwich panels feature outstanding load capacities and a structural integrity that often make the products an excellent choice over polycarbonate systems and insulated glass units. The company's translucent panels yield museum-quality diffuse daylighting that are ideal for facades, skyroofs®, skylights and canopies used in projects of all types.

Daylighting buildings with Kalwall

Kalwall's translucent panels offer versatility, durability and performance that can outperform many conventional vision glazing systems. The company's high-performance glazing products are unique to the industry and allow architects to create bright, comfortable spaces. Translucent building products diffuse natural light, reduce glare, help to control solar heat gain, enhance visual connections with the outdoors, optimize daylight harvesting and provide additional design flexibility.

Kalwall's newest products allow architects and specifiers to further mix and match facade elements with double or triple glazed units, spandrels and other claddings using translucent panels that offer privacy, eliminate the need for secondary control systems, meet bird-friendly requirements, while also being low maintenance and resistant to graffiti.

Introducing Kalwall 175CW

After extensive testing and numerous installations, Kalwall has recently put a new product on the market to offer more design freedom to architects and specifiers. Kalwall 175CW is the first in a series of new translucent insulated glazing units (TIGUs) for facade applications.

The TIGUs are specifically developed to be compatible with most third-party vertical curtain wall systems available on the market, allowing architects to combine Kalwall with other infill glazings and opaque claddings. The product provides the energy efficiency of triple-glazed units with excellent thermal and daylighting performance as well as solar heat gain control. Kalwall 175CW is currently available for vertical facade applications only.

Lightweight and versatile

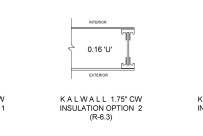

Kalwall 175CW TIGUs are lightweight at less than 7.5 kilograms per square meter (1.5 pounds per square foot). The units are nominally 4.5 centimeters (1.75 inches) and fully thermally broken. They are also strong and highly impact-resistant. TIGUs for facade applications are available up to 1.5 x 4.6 meters (5 x 15 feet). Three U-factors are currently available: 0.28, 0.16 and 0.14. And the product comes with up to a ten-year warranty on abnormal color change, fiberbloom and the performance of its coating.

Curtain wall compatibility

Kalwall 175CW takes its name from its nominal 1.75 inch thickness, the dimension which matches the thickness of triple-pane insulated glass units (IGU) that most modern curtain wall systems are designed to accept within the glazing pocket. For projects where the curtain wall or storefront system specified by the customer can only accommodate double pane IGUs with a typical thickness of 2.5 centimeters (1 inch), a 7 centimeter (2.75 inch) panel with a curtain wall adapter can be specified.

Curtain wall systems are available in many configurations. The most common include four-sided pressure plate systems to which Kalwall 175CW is compatible. It is not made to suit silicone structural glazing (SSG) curtain wall systems at this time.

Grid patterns

A series of standardized Kalwall 175CW grid options offer a range of orthogonal patterns for all facade types. Shoji-reverse and Ladder patterns are the product standards, with Shoji, VertiKal, Tuckerman and others as optional patterns. Kalwall 175CW panels are available in both 1-way and 2-way grid patterns with no diagonal mullions or muntins internal to the panel. All 175CW grid-cores use a thermally-broken I-beam. The thermal break is approximately 2 centimeters (0.75 inches) wide and utilizes a low conductive FRP as the web material.

Structural behavior and panel sizing

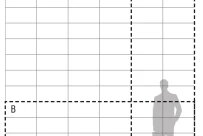

The maximum allowable panel deflection at the midspan is based on ASTM E-72 per the manufacturer’s recommendation. Given the four-sided capture configuration of curtain walls, Kalwall 175CW panels can most efficiently span in the short direction with continuous cross-mullions.

Panel sizes are available up to 1.5 x 4.6 meters, or 7 square meters (5 x 15 feet, or 75 square feet). Typical panels are 1.2 and 1.5 meters (4 and 5 feet), designed according to normative curtain wall vertical mullion spacings. Maximum sizes are set at 1.2 x 4.5 meters (4 x 15 feet) and 1.5 x 4.5 meters (5 x 15 feet).

Better than IGUs?

Insulated glass units (IGUs) with areas larger than 4.6 square meters (50 square feet) are typically considered large or ‘jumbo’ formats, and come with additional material costs, weights, tempering and more expensive handling requirements. Kalwall 175CW panels are comparatively lighter and cheaper, making this solution even more attractive as sizing get larger.

There are other advantages to the Kalwall product. These include glare-free daylight quality, reduced reliance on additional shade controls, higher glazing performance in terms of U-factors and SHGC, eased options for mixed glazing in combination with vision glass, privacy and security, shatterproof qualities, lower embodied carbon, and reduced light pollution on the exterior of buildings.

Innovative fiberglass reinforced polymer (FRP) faces

Fiberglass reinforced polymer (FRP) faces refer to the outer layers of a composite material that combines fiberglass reinforcement with a polymer matrix, typically a resin. These faces play a crucial role in determining the performance, strength, and durability of the composite material.

Kalwall has developed a full line of high performance FRP face sheets including its Super Weathering (SW) formulations that are unrivaled in the industry. Translucent White and Crystal are standard. Kal-tints are optional. Optional FRP finishes are available for interior faces only.

A history of making translucent building products

Kalwall has a rich history that spans over seven decades, marked by innovation and a commitment to transforming spaces through advanced daylighting solutions. The company was founded in 1955 by inventor and entrepreneur Robert R. Keller in Manchester, New Hampshire, USA.

Kalwall initially gained prominence with the development of the first translucent sandwich panel. This breakthrough in building materials allowed for the creation of structures with enhanced natural daylighting while maintaining insulation and privacy. Made of a unique composite material that diffuse sunlight evenly to reduce glare and shadows, this technology became a game-changer that has influenced the aesthetics and functionality of many buildings across various industries.

Over the years, Kalwall has refined its products and expanded its portfolio to accommodate building surfaces beyond facades. The company's commitment to sustainability and energy efficiency are evident as Kalwall panels are recognized for their ability to optimize natural daylight, reducing the need for artificial lighting and lowering energy consumption in buildings.

Kalwall's impact extends globally, with its architectural solutions featured in a diverse range of projects, from commercial and educational buildings to sports facilities and museums. The company's emphasis on high-quality materials, cutting-edge technology, and collaboration with architects has solidified its reputation as a leader in the daylighting industry.

Reference projects

Kalwall products have been incorporated into projects around the globe seeking high-quality interior daylight conditions. Here are four projects selected by Archello as representative of Kalwall's portfolio:

Industrial Design Center at Howest

Howest, de Hogeschool West-Vlaanderen is a university of applied sciences with multiple campuses in Belgium. Kalwall’s lifespan and energy-efficient technology helped this project for a new industrial design center meet its sustainability goals. The highly insulating material reduces HVAC loads while autonomous daylighting reduces electricity costs.

The benefits of daylighting for education spaces are well proven. Kalwall scatters full-spectrum visible light waves to yield usable light that penetrates deeper into spaces, enhancing occupant comfort and wellness while reducing reliance on artificial lighting. The advantages of diffuse, full-spectrum light compared to alternative daylighting options include better visual acuity, color rendition and focus. All these benefits work together to create an ideal environment for working students.

The Odeon Theatre in Bournemouth, UK is a transformation of a former bus station into a sprawling cinema complex. The project features a signature facade with over 1,000 square meters (3,000 square feet) of Kalwall panels. The translucent cladding encapsulates the building across all nine elevations and encloses the external fire escapes. At night, the cladding creates a warm, inviting and ethereal glow that serves as a beacon for visitors and mitigates any issues with light pollution to the surrounding residential and commercial buildings.

The system enhances simplicity by doing away with the need for blinds, curtains or solar control. Even on cloudy days, the interior is flooded with natural daylight, which means less artificial lighting and, because Kalwall is highly insulating, energy costs are reduced.

New York Psychotherapy and Counseling Center

This 1765 square meter (19,000 square foot) expansion transformed a former single-story warehouse into the home of one of the New York Psychotherapy and Counseling Center’s (NYPCC) Child and Family Mental Health Centers. Two new floors clad in Kalwall translucent sandwich panels serve as a symbolic, signature feature, glowing softly at night and creating an illuminated neighborhood landmark. The use of Kalwall reflects a mission to bring proven health benefits to building occupants. Diffuse natural light bathes the interior of the Center’s upper spaces to create a calming atmosphere that has a profound effect on physical and mental states. Kalwall’s full-spectrum daylight was chosen to improve mood, mental awareness and visual clarity, leading to a decrease in eyestrain, headaches and insomnia.