What was the brief?

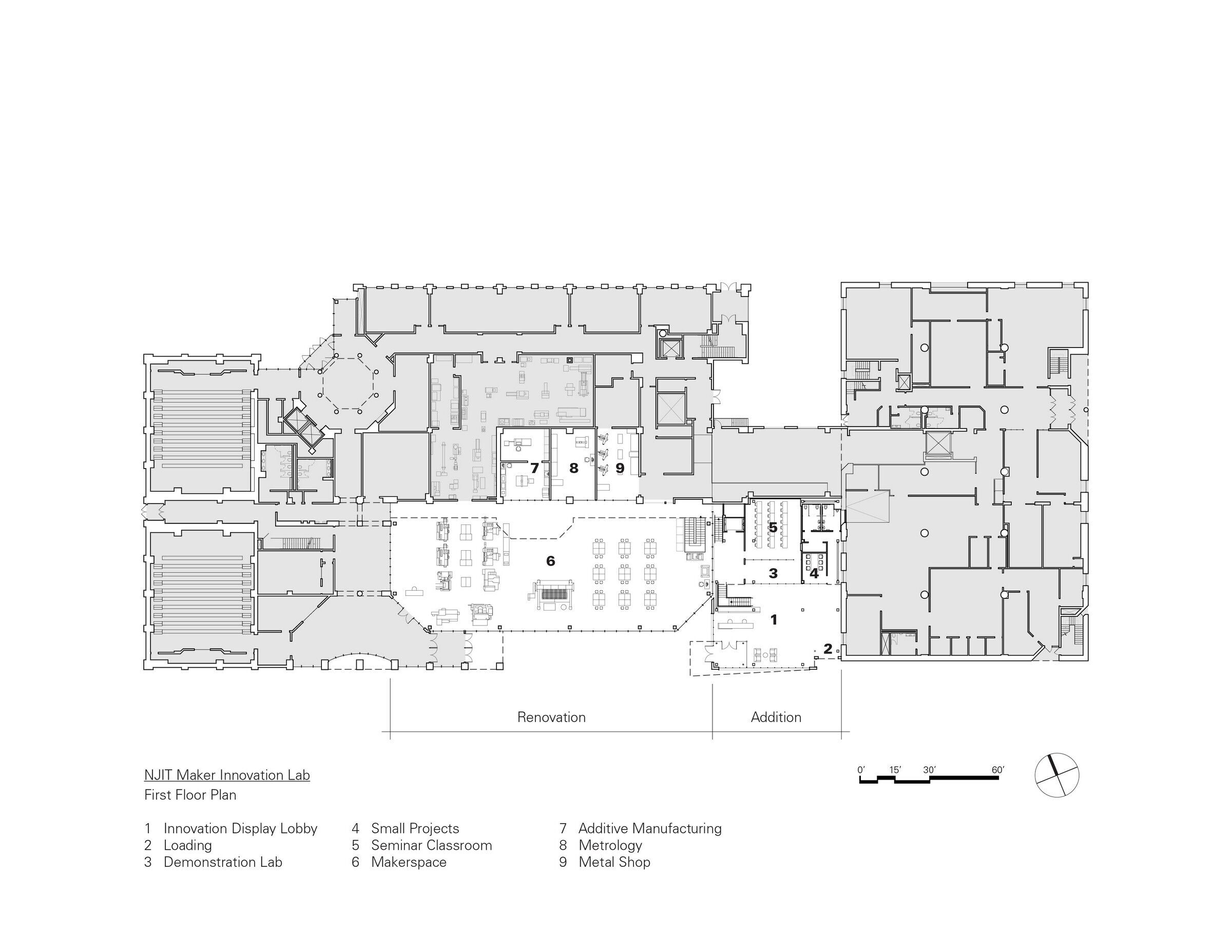

The NJIT Makerspace Lab, located in the University’s Guttenberg Information Technology Center, is designed to support innovative interdisciplinary programs that promote entrepreneurship. The 14,000-square-foot lab is a resource for students and faculty to develop theoretical concepts into marketable prototypes. The program and design of the Makerspace lab promotes collaborative creativity through interdisciplinary teamwork using a variety of digital mediums and mechanical tools.

The Makerspace is an open workspace and lab for students and faculty to engage in innovative and entrepreneurial activities. The interior reflects the activities of the academic program: inherently flexible for reconfiguration, adaptable for multiple applications, and industrial for durability. The transparent exterior façade in this centrally located site displays the innovative activities within and engages the entire campus and community. The Makerspace Lab hosts diverse social, training, and lecture events throughout the year that bring students, faculty, and industry partners together across disciplines to learn and socialize.

What were the key challenges?

The key design and construction challenges for the Makerspace were as follows:

- Conceptualizing the approach, location and the phasing for the Makerspace within a complex of multiple departments and existing conditions/systems while staying operational

- Integration of the Makerspace program equipment within an existing facility, i.e. structurally reinforcing the existing floor while the building was occupied

- Designing mechanical requirements that concurrently addressed an open flexible environment and points of specific requirements

- Construction of the Makerspace infill addition in a site surrounded on three (3) sides with existing and occupied buildings

What materials did you choose and why?

The Makerspace Lab hosts diverse social, training, and lecture events throughout the year that bring students, faculty, and industry partners together across disciplines to inspire creative thinking, collaboration and entrepreneurship.

The architectural design and the materiality enhance the program by selecting an exterior façade system to facilitate the engagement between the Campus, the Community and the Makerspace by displaying the creative innovations within the building. The exterior materials are accentuated by selecting complimentary interior materials that are inherently flexible for reconfiguration, adaptable for multiple applications, and industrial for durability.

- Clear insulated curtain wall system for transparency and connectivity

- Metal panel system to integrate the new addition with the existing facility

- Sealed and painted concrete floors for durability and an industrial aesthetics

- Painted and exposed ceilings to promote an industrial working environment

- Coiling overhead reels for power and utilities to provide multiple collaborative settings and flexibility

- Industrial mobile furnishings for appropriate work surfaces and durability

Material Used :

1. Facade cladding: Aluminum composite wall panels (by Alpolic)

2. Flooring: Seamless epoxy flooring (by Stonhard)

3. Doors: Solid-core wood veneer-faced; white oak rift cut (by Ceco)

4. Windows: Glazed aluminum curtain wall (by YKK AP America Inc.)

5. Roofing: EPDM single ply membrane wall (by Carlisle Syntec Systems)

6. Interior lighting: Linear pendant LED (by Focal Point Lighting)