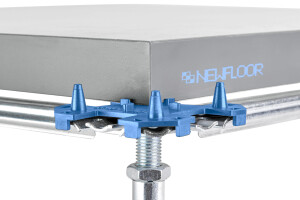

A combination of many materials of various nature assembled in a single panel, the floating element of the entire system which, rested on steel supports, creates the system that raised the floor off the traditional flooring to a higher height, creating a gap under the surface where technical building systems can be installed: electrical, plumbing, electronic and air conditioning. The floating floor system allows for perfect modularity and element interchangeability allowing the area underneath to be inspected at any time, guaranteeing easy system maintenance over time. This application offers multiple advantages in the work-flow for the construction of a building (it is not necessary to wait for the testing of structures and systems before proceeding to lay the floor, allowing time to be saved in the implementation and conclusion of general jobs). This type of floor is ideal for installation in offices, stores, data centers, restaurants, pavilions, etc.

Generally square or rectangular, made up of various layers, panels are characterised by an internal core that guarantees the floor’s primary technical performance and are lined on the top by the finishing material expressly requested by the purchaser. A thin layer of aluminium and/or steel is usually applied to the lower part of the core to act as a vapour barrier. A PVC border is applied to the perimeter to complete the module guaranteeing floor comfort and acting as grouting.