Rundzwei Architekten has designed a private home with a facade and roof clad in panels of cork sourced from Portugal. The rectangular panels provide a thermally-efficient and acoustic skin for the house, as well as lend it a natural and monolithic expression.

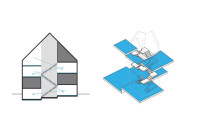

The ‘corkscrew house’ by Rundzwei Architekten culls its name from the helical, split-level layout the designers conceived for it as a workaround to the site’s volumetric restrictions. “Our client wanted a fairly large house with respect to what the local planning regulations allowed, which was technically a one-story building of 100 square meters,” says its architect, Marc Dufour-Feronce, who worked on the project with his partner, Andreas Reeg.

A previous designer engaged for the project had been unable to satisfy the client with the amount of space generated in his proposals. “We like challenges and wanted to see what we could do to push the site’s boundaries,” says Dufour-Feronce. So, with his team at Rundzwei, he devised a stepped layout using a series of split levels. Daylit spaces were set partially below ground as well as within the roof: its bedroom, for example, is set about a meter below grade.

The rooms spiral about a central atrium to create a complex residential volume. By arranging the building this way, the architects achieved a gross floor area of over 300 square meters. The home can be divided into two apartment units as a response to the client’s request for future adaptability. The below grade portion is constructed in rammed concrete, while the upper levels are framed in timber. Cork panels clad the facade and roof to yield a sculptural envelope punctured by large windows that are stepped in correspondence with the floor levels, and which animate the monolithic form with a constellation of openings.

The site of the corkscrew house is located within the access space to the former Tegel Airport. “The planes were always flying over the site and it was very noisy,” says Dufour-Feronce. The residence demanded an acoustically insulated envelope for a comfortable interior environment, free from the roar of airplanes passing overhead. The client, who enjoys sitting outdoors in the rain, also requested a cladding material with noise reduction qualities on its exterior surface to reduce the drumming sound of rainfall.

“As an office, we are always eager to use building products which are not carbon-based,” says Dufour-Feronce. Rundzwei has put particular focus, for instance, on designing buildings with timber structures. “We had a coworker from Portugal who suggested using cork for this project, because it is a natural material with the capacity to be both insulating and exposed,” he says. The architects found the proposition interesting and traveled to Portugal to speak with one of Europe's largest family-owned manufacturers of cork products that range from wine stoppers to building materials. According to Dufour-Feronce, the team met several people in Portugal who had used cork in construction, but mainly as an insulative material which was then rendered on top of. “Not many had experience working with exposed cork,” he says.

The architects visited a school project in Lisbon clad in cork on a site along the Tagus river. “The facade was a few years old and it had almost no damage, even with its harsh weather conditions. It was quite pretty,” says Dufour-Feronce. “And opposite the school there was another building with aluminum cladding and glass balustrades on the balconies. This one looked quite dreadful due to the sun, rain and salty wind.” The only visible damage to the school enveloped in cork, according to the architect, was that a small area of the cladding had been picked out by birds. “But we learned that, if that happens, you can just cut out a portion of the cork panel and replace it with a new piece.” Over time, the replacement blends in with the rest of the facade.

According to Dufour-Feronce, when cork is first received from the factory it is coffee-brown in color. But once left exposed to the sun, the color gets lighter. The architects brought a sample back to Berlin and left it exposed to the elements at their office to better understand the changing finish. The sample was shown to the client to describe how the envelope of her home might look in the future. “The color change is something which we all found quite unusual,” says Dufour-Feronce. “Nowadays other architects ask us how we managed to achieve the light color on the corkscrew house, whether we painted it or stained it. But we didn't, it just happens naturally.”

Dufour-Feronce admits that using the material was a rather experimental endeavor: there were no cork building precedents he knew of in northern Germany at the time, and, consequently, no builders with experience installing the material. The client was nevertheless convinced that cork would be worth trying, with the caveat that it comes with a guarantee for at least ten years. “We asked the manufacturer for a certificate, and they wrote us one,” says Dufour-Feronce. “It covered everything except for bird protection.”

Portugal, and in particular its arid southern Alentejo region, is one of the world’s main cork producers, followed by Spain’s Iberian peninsula and smaller areas of North Africa and France. Cork is the bark harvested from the cork oak tree native to this climatic zone with warm summers and moderate winters.

Cork is a durable, impermeable, fire-retardant, mold-resistant and lightweight material that provides thermal and acoustic insulation. Cork is also a sustainable material, easily recyclable and produced by trees that are not felled: the bark is stripped from live trees which continue to grow and sequester more carbon as they age. Cork is stripped from tree trunks by hand with the use of an ax once the trees are some 25 years in age. The stripping typically continues periodically each nine years. Cork trees can live 200 years or more, and so some of the oldest specimens have been stripped upwards of 20 times. A single tree can yield enough cork mass over its life to produce, for example, hundreds of thousands of wine stoppers.

When trees are stripped for the first time, the quality of the cork tends to be poorer; this stock is generally used by the building industry for products such as insulation. Alternatively, the cork powder left over from producing wine corks can also be pressed into sheets for use in the construction industry. Granulated cork waste is formed into facade panels under pressure and heat. “No chemical or glue is used in making panels, because the cork contains natural resin which binds the material,” explains Dufour-Feronce. “Then regular saws can be used to cut the panels into different thicknesses, or a CNC router can be used to shape them into chairs and other products.”

The corkscrew house makes use of cork panels that have a nominal thickness of 140 millimeters, a dimension deemed adequate for waterproofing the building. The home’s panels are sized at approximately 1 meter by 60 centimeters, and the architects employed a vertically-formatted tiling pattern which makes the house appear taller.

The architects wished to install the cork in an environmentally friendly manner that avoided the use of glues and adhesives. The panels are fixed manually with the use of screws. “At first we were worried that the screw heads would be visible everywhere,” says Dufour-Feronce. “But we noticed quite quickly that this is actually not of any concern, because the screws sink into the elastic cork and then completely disappear from view. It’s difficult to find them afterwards.” The facade panels are fixed directly to the home’s timber framing. The roof panels, however, are fixed to timber battens on corrugated metal.

One challenge for the project was finding a local construction company that would be willing to install the relatively unknown material. “To convince them that it was doable, we ordered blocks of cork and said: ‘Have a look, try it out, and see whether you are capable of coping with it’,” says Dufour-Feronce. “It was at first assumed to be a very time consuming process. But then it turned out to be incredibly fast, because it is actually very easy to do. The builders were amazed.” No special tools were necessary. The installation could be completed by a local construction company with no former experience installing the material, using typical handheld and table saws on site.

The project was detailed according to the architects’ desire to express a monolithic, sculptural form. No rain gutters or drain pipes, for example, are visible. Linear profiles at the roof pitches help direct the water into four steel downpipes hidden within the building corners. “We also wanted very sharp edges, for a modern look,” says Dufour-Feronce. The corner panels were cut at 45 degrees on site to achieve the building’s clean angles.

The building also makes use of other environmentally friendly materials, in addition to cork. Wood fiber and cellulose insulation, for example, are used to further insulate the exterior walls. Humidity-absorbing timber and gypsum fiber boards as well as permeable paints help the interior spaces breathe, and eliminate the need for an active ventilation system. And solar panels integrated into the cork roof supplement the home’s heat storage system.