The property at 1 Lonsdale has been owned by a local family for three generations. When the existing building was reaching the end of its lifespan, the family chose to use this as an opportunity to develop a new three storey, Passive House building that would serve as a sustainable benchmark for the fast changing Lower Lonsdale District.

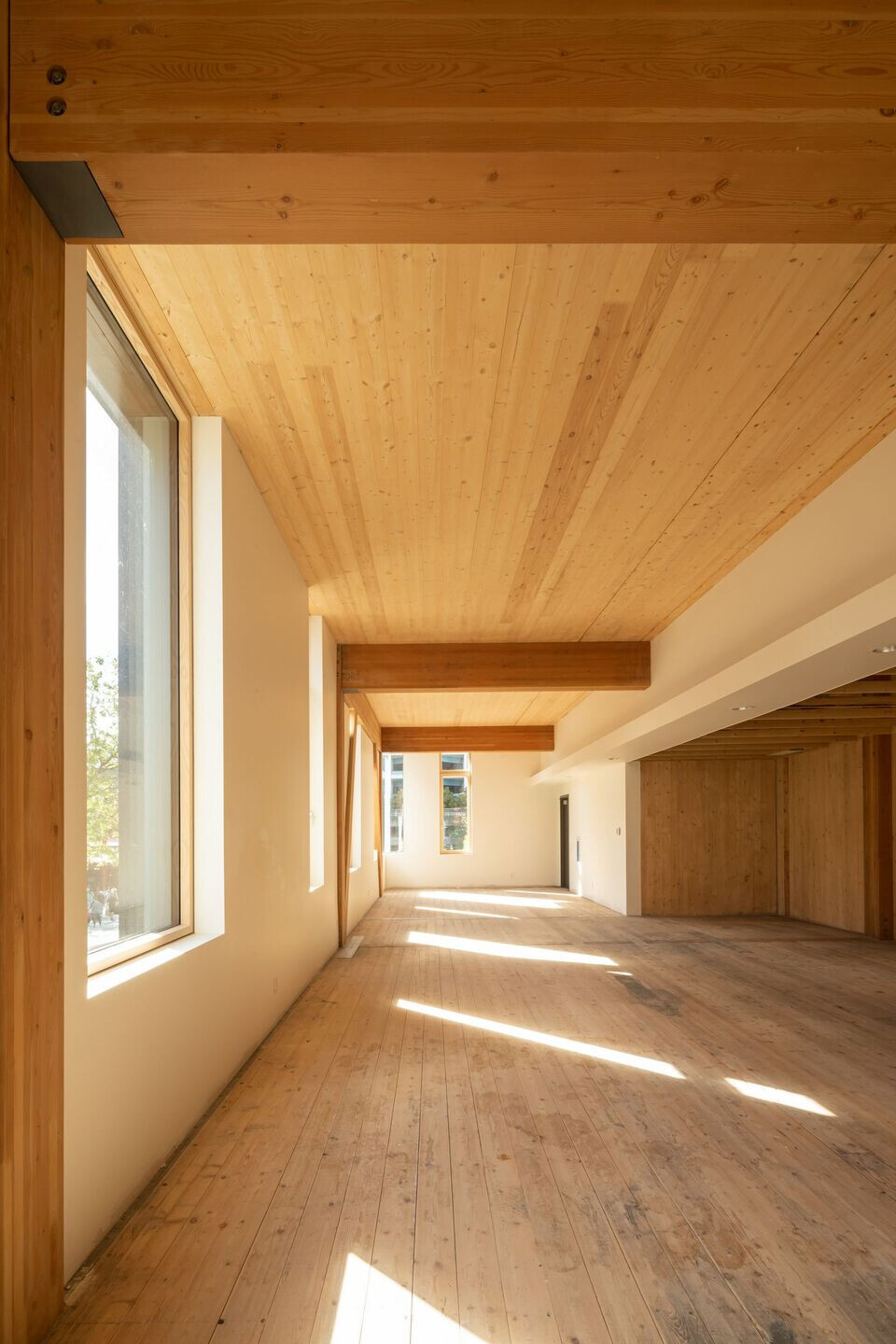

The intent of the design was to create a contemporary interpretation of the brick clad, heavy timber, warehouse buildings that formed the backbone of the working waterfront. Along with the sustainable ambitions for the project, the new building presents the Lower Lonsdale District with the familiarity and ‘grounded’ feeling of a dark, glazed brick building that reads as a ‘skin’ for the mass timber frame, as opposed to a traditional ‘solid mass’ building. The fenestration on the building’s upper two floors has been ‘randomly’ distributed to offer visual interest and relief from the predictable facades typical in commercial buildings. Special attention has been given to signify the corner of Lonsdale Avenue and Carrie Cates Court by eroding the brick facade on the upper floors to express the mass timber structure through a PH curtainwall system, while offering the upper floor occupants stunning views of Vancouver harbour.

Urbanely, the building supports the development of the streetwall with the Polygon Gallery, while creating a comfortable scale and accessible street level for pedestrians. The building’s ground floor has been designed to ‘open’ onto Carrie Cates by incorporating floor to ceiling, PH triple glazed windows and sliding doors. With the opening of the new Polygon Gallery and the activation of Carrie Cates, the new restaurant will offer a south facing exterior deck and ‘wrap’ restaurant row onto Carrie Cates. The result will be the further development of the Lower Lonsdale arts and cultural district.

All this said, the most remarkable aspect of the project, is the innovations in pre-fabrication and mass timber construction methodologies. The project faced a number of building code challenges including the use of a CLT and glulam structure and the need for a zero lot line ‘non-combustible’ party wall. Factoring in the complexity of PH air tightness and restricted thermal bridging requirements, a system of pre-fabricated insulated, 2x8 vertical wall panels were used for the three ‘visible’ sides of the building. A series of CLT panels with the membrane, exterior insulation, and cladding pre-installed were then used to create the north wall whilst providing the necessary fire rating.

In the simplest terms, the main mass timber structure was erected and then the exterior, PH envelope was sleeved over it, all in just 10 days of construction time. This extraordinary achievement was accomplished by the deep integration of the design and engineering team, with the general contractor, the prefabrication and mass timber suppliers, window manufacturers, and the local authorities.

As we face the overt challenges of the climate crisis, we strongly believe that this type of innovative approach to construction will become a necessity in the very near future.

Material Used:

1. Facade cladding: Masonry: Norman Size Obsidian Matte, Interstate Brick

2. Doors: Wood Doors, Entrada PH, Optiwin

3. Windows: Triple Glazed, Metal Clad Windows, Optiwin Resista, Optiwin

Triple Glazed Curtain Wall, Glasbox CW2.0, Glasbox

4. Roofing: 2 Ply SBS, Sopralene Flam Stick & Sopraply Traffic Cap, Soprema

5. Glulam Columns & Beams D-Fir Glulam, Structurlam

6. CLT Panles 5-Ply CLT, Structurlam

7. Elevator Schindler 3300, Schindler

8. Prefabricated Wall Panels BC Passive House

9. Insulation Exterior Insulation, Cavity Rock, Rock Wool