1. Basic information

B10 is a research project located in the Weissenhof Estate in Stuttgart. The plot of land was originally home to a residential building designed by the architect Richard Döcker; however, it was completely destroyed during a bombing raid in the Second World War. After it lay unused for nearly seventy years, the district council of the City of Stuttgart decided in the autumn of 2012 to temporarily make the land available for an experimental research building to be erected.

In future, we will live in more densely populated and multi storey structures. Open spaces, green areas and elements generating energy will be located on different levels; they will be just as much an integral component of the built-up environment of tomorrow as mobility and flexible living accommodation suitable for people of all age groups. At the present time we do not have the required methods and technologies at our disposal to really be able to design and build this world for the long term. B10, which is to be considered a small prototype element of this world, should deliver valuable insights towards achieving this goal.

The architectural design is based on the Triple Zero concept developed by Werner Sobek. The building is not only designed to fulfil the highest demands on aesthetics and user comfort, but also to generate more energy than is needed to run the house (zero energy), to produce no emissions whatsoever (zero emissions) and to be returned fully to the materials cycle (zero waste) at the end of its life.

The single-storey building not only turns to passive measures (such as particularly efficient thermal insulation) that are essential for the transition to renewable energy sources to take hold in urban environments, it also makes use of diverse active measures. Thanks to its predictive, self-learning building automation and control system it is the first fully functional Active House in the world.

Strict historical preservation orders needed to be taken into consideration with regard to cubage, appearance and the foundations when erecting the building. It was not an option for work on B10 to be allowed to damage the remaining foundations of the previous historical building.

2. Energy considerations

Despite difficult boundary conditions presented by the plot of land the objective of the design was to achieve a surplus of energy amounting to approximately 200%. In addition to diverse passive measures, a prerequisite to achieving this goal was also the Active House principle: a predictive, self-learning energy management system that makes it possible to significantly increase the surplus of regenerative energy generated on-site above and beyond usual levels. The building is able to continuously adapt to changing conditions and requirements of indoor and outdoor areas; this enables it to generate approximately 200% of the energy required to power building services and controls as well as household electricity by itself.

As well as active measures such as building automation and control, a prerequisite to achieving the targeted energy goals also includes implementing diverse passive measures necessitated by the conditions presented by the building plot. For instance, the structure is completely closed on three sides and boasts extremely well insulated wall constructions to keep thermal losses as low as possible; by contrast, the house front facing towards the street, in other words facing north-west, is fully glazed. A newly developed vacuum insulating glazing ensures high levels of transparency and at the same time very good thermal insulating properties.

Thanks to its alignment and architectural style the building not only fulfils its character as an object of visual interest, but also makes it possible to increase passive solar energy gains from the low-lying sun in the west during the winter months. Moreover, the compactness of the building offers a good surface area to volume ratio while at the same time maximizing the roof area that can be utilized to generate energy by combining photovoltaic and solar thermal collector systems.

3. Prefabricated and modular

The cubage can be traced back to the stated energy parameters as well as an innovative planning and building process. Planners and implementers worked extremely well together from the beginning of the initial concept phase; they were then able to work in parallel development processes during a second phase to achieve innovative solutions at the interfaces of the different disciplines. That was the only approach possible to be able to surmount the numerous technical requirements resulting from the high degree of innovation demanded of the building within the extremely tight time frame available.

The objective of the project teams was to overcome the usual demarcation of disciplines and attain the accompanying concentration of minds to achieve non-series on-site production. Thanks to the virtually complete prefabrication of the building under clean factory conditions it was possible to deliver (in two parts) and erect the structure as well as install the glazing in just one day. All of the interior finishings including fitted kitchen and bathroom furnishings were already installed at this point in time.

Industrial prefabrication and the suitability of the structure for transporting were important considerations underpinning the overall concept.

Four modules were designed and prefabricated independent of the remaining building in order to be able to increase the degree of prefabrication and at the same time facilitate a maximum of flexibility for subsequent new planning tasks. These modules offer space to install the "electrics", "building services equipment", "kitchen" and "bathroom". The role model for these technology racks is the vehicle manufacturing industry that, to increase efficiency, prefabricates individual elements independent of the actual production process and later builds them into the vehicle as complete modules.

The modules are designed to allow them to be joined together in any order. That makes possible a flexible building concept that can be extended as required and adapted to local conditions and user requirements. At the same time the compactness of the modules guarantees that the actual living area is not taken up with unnecessary infrastructure functions. This approach not only gains valuable living space from the same amount of cubage, it also makes it possible to plan the building technology as a holistic system. The length of cables and pipes is minimized, their positions are determined in 3D and they are placed only in specified parts of the building envisaged by the design.

The modular principle and simple adaptability also applies to the interior. For example, mobile, easily installed and removed dividing walls and sliding glass doors make it possible to subdivide the large open room to be used for different purposes.

The modular principle of the design and spacial construction makes it possible to extend and adapt the building concept of the B10 to meet different requirements. It is possible to install the system at different locations, and it can be adapted and expanded to meet individual needs that take into consideration different user demands as well as climatic, regional and cultural aspects as well as building regulations.

One very important aspect of this consideration is to specifically increase the density of urban areas. The goal is to make transforming and extending these new urban areas as easy as possible and with as much flexibility as possible.

4. Deconstructability

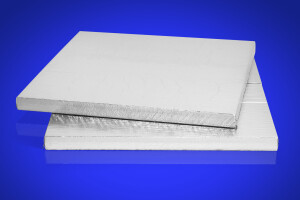

The modular design is not only beneficial to the building process, but, by extension, the deconstruction process as well. A non-destructive process of deconstruction and sorting of the different materials used in the building takes the place of a wasteful and destructive demolition process. This suitability for deconstruction was taken into consideration at the beginning of the planning phase and is an integral part of a conscious understanding of the built-up environment as an ephemera. This aspect is particularly important, especially when considered in the light of the architectural and cultural significance of the Weissenhof Estate in the middle of which the building has been placed. The building understands itself to be a guest temporarily resting in its present environment. It has been designed so that it can be deconstructed or moved without any difficulty at the end of its allotted occupancy. The building itself has been designed as a highly insulated timber-panel construction. To guarantee perfect recyclability the timber components are neither painted nor coated in any way. The walls consisting of untreated timber are covered inside and out with a textile fabric – an easily convertible and deconstructed construction that can be sorted into homogeneous lots. This made it possible to do without the otherwise standard exterior rendering. Neither were any classic foundations or cables and pipework laid in the ground.

5. Urban embedding

Because of its character as a shop-window project and its understanding of its presence in the Weissenhof Estate as a guest, B10 has been consciously oriented towards the street – whereas the residential units in the surrounding houses face away from the street. On the one hand B10 understands itself to be an independent, modern addition to its surroundings. On the other hand, thanks to its understated volume, its simple cubic design and reduced colouring, B10 blends in perfectly in the Weissenhof Estate, which is protected by a preservation order. With its technology, its residential quality and its sustainability qualities the building absorbs the ideas and objectives of classic modernism and guides them onward towards the 21st century. As was the case when the Work Union estate (Werkbund) was built in 1927 B10 seeks to demonstrate new forms of planning, building and living as well as examine new materials and designs. One important innovation in this sense is the control of the building by means of a predictive, self-learning building automation and control system as well as coupling the energy streams between the building, the electric vehicles and the surrounding buildings (in this case with the Weissenhof Museum located in the LeCorbusier house) – in other words, creating a smart grid in the neighbourhood.

6. Adaptivity

The patio at the front of the building is attached to the steel beam frame on which the house itself stands. The patio is subdivided into four movable, hydraulically powered elements that can be rotated upwards 90° to completely close off the fully glazed side of the building. This feature additionally improves the thermal insulating properties of the building envelope during the night or when the user is absent. For that reason, the patio elements are covered with the same white fabric as the other outside walls; the fabric is visible when the elements are closed (meaning upright) and can also be illuminated during the night by background lighting. When the patio elements are open, meaning in a horizontal position, they practically double the usable area outside the house.

When folded down the west facade doubles up as a patio and also provides access to the building. The electric Smart vehicles that belong to the research building are also able to access the building via this entrance area. It is possible to drive into the living quarters of the building to fulfil charging and discharging requirements within the living quarters. As the vehicle is halted on a turntable set in the floor, it is possible for it to exit the building facing forward. One objective is to investigate to what extent it is possible to make it easier for older and/or disabled people to get into and out of the vehicle. A further objective is to investigate if parking an electric vehicle in temperature-controlled indoor rooms can increase its range (because less electricity is needed to heat or cool the vehicle when driving).