What was the brief?

The initial brief received from the client required 300,000 SF of space for the University’s Chemistry Department, including teaching, faculty research and office spaces. The building had to both modernize and reinvigorate the aging department through the provision of a new, world-class facility that could help them attract leading chemists from around the world. It also needed to be environmentally responsible in line with the University’s sustainability strategy.

Located within the University’s “Natural Sciences Neighbourhood” adjacent to the Physics, Genomics and Molecular Biology buildings, the Frick Chemistry Laboratory needed to foster interdisciplinary study and research and to enable shared and efficient use of facilities.

What were the key challenges?

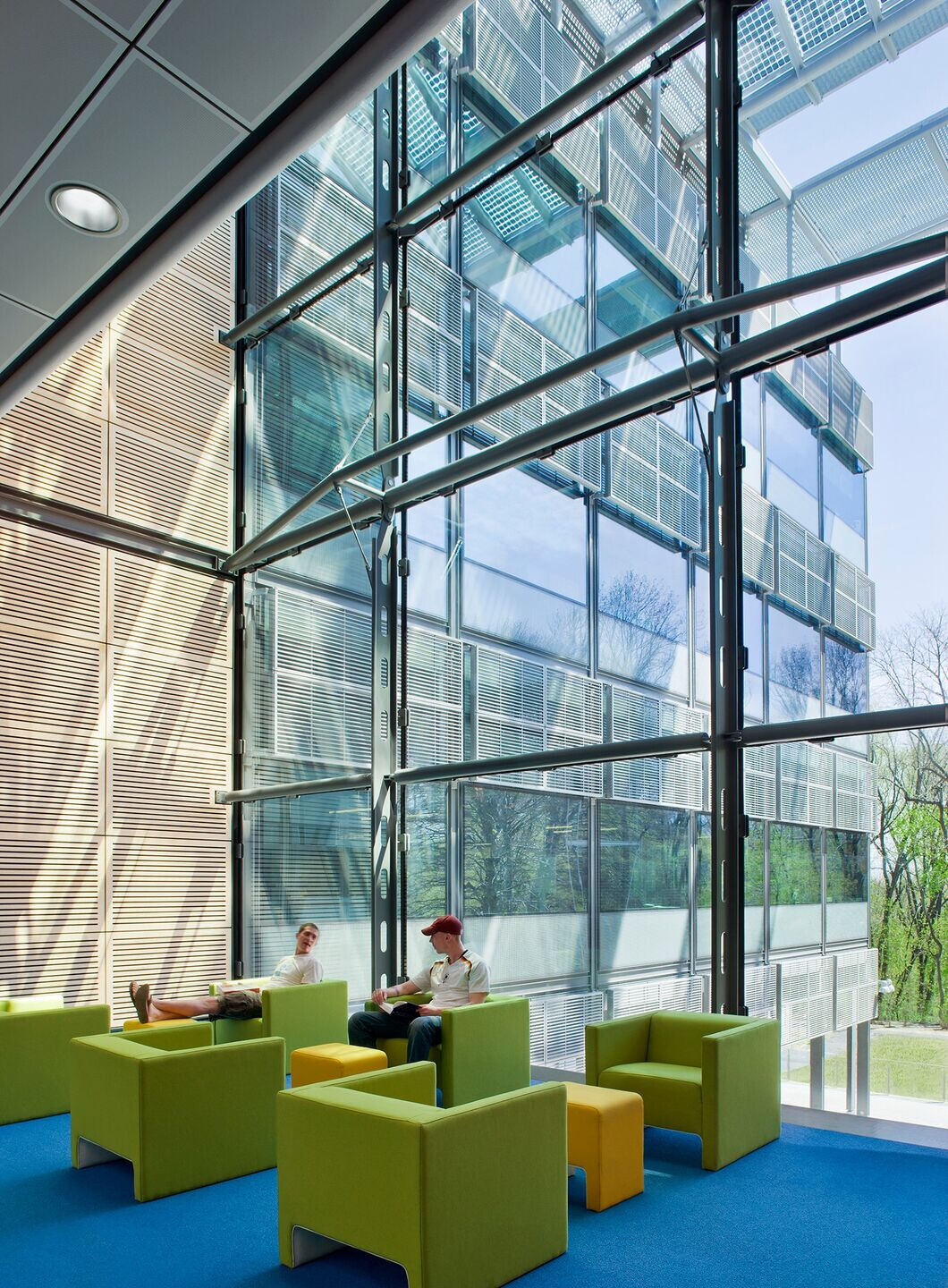

One of the principal aims of the design was to set a new standard in energy-efficient design for chemistry research buildings throughout the US. As such, the project incorporates a number of sustainable features including large photovoltaic panel array which is located above the glazed Atrium roof and cleverly works “double-duty” as an integrated shading device, an engineered façade system, greywater recycling, chilled beams and extensive use of natural materials. Mechanical systems in the building are designed to optimize transfer of cooled and heated air from offices through the atrium and into the laboratories, reducing the amount of outside air that must be conditioned to meet the ventilation demands of the laboratories.

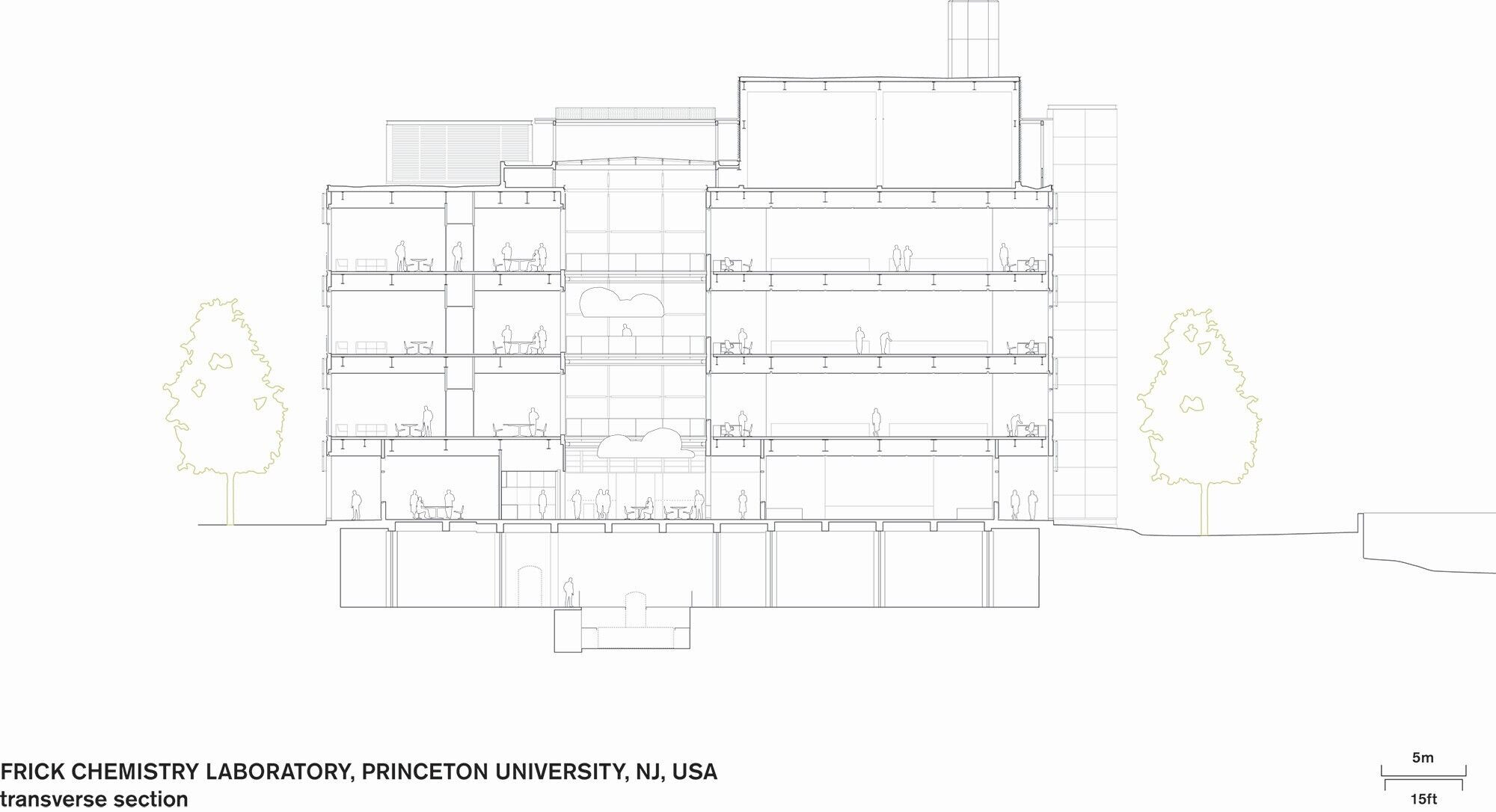

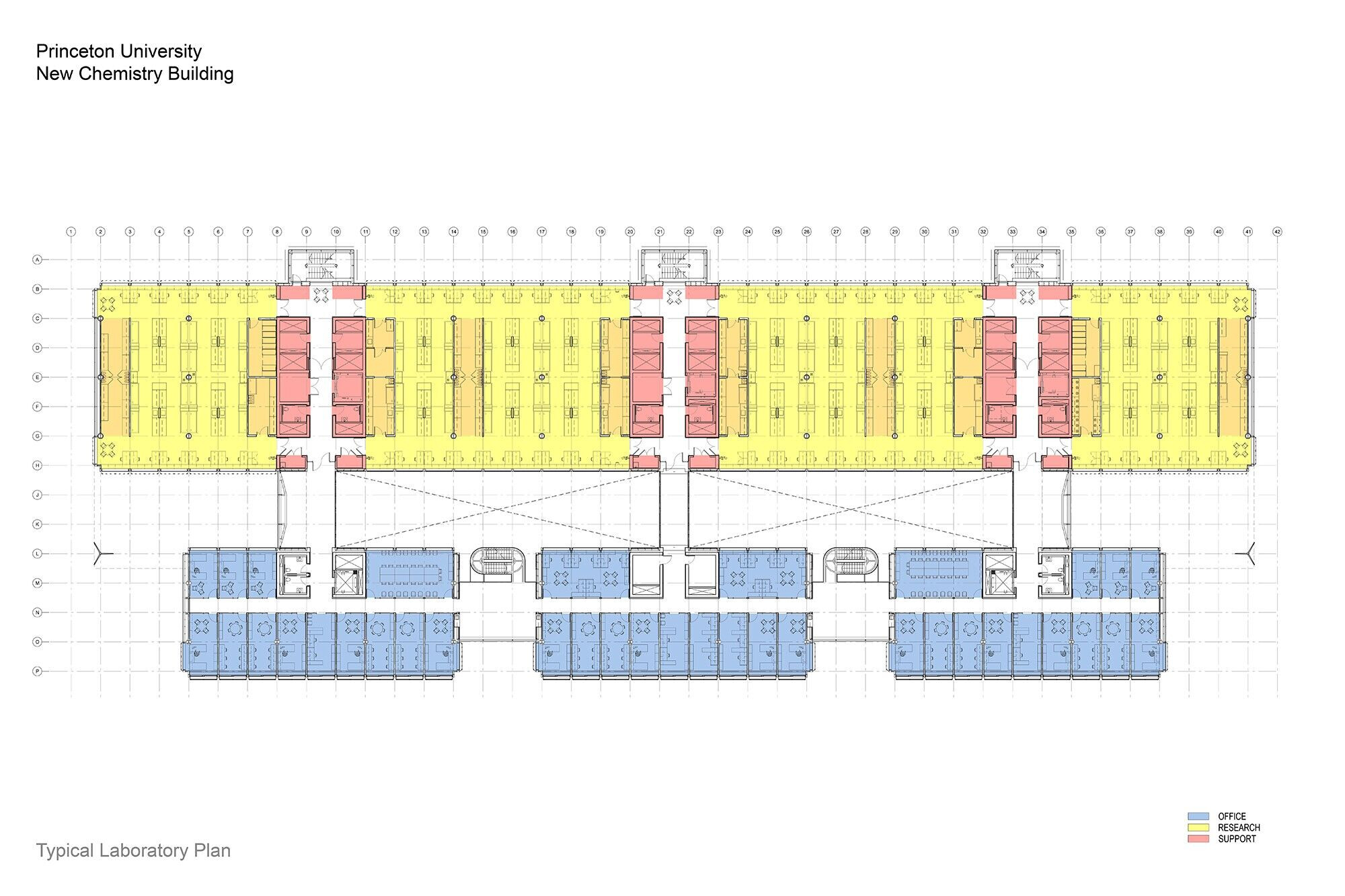

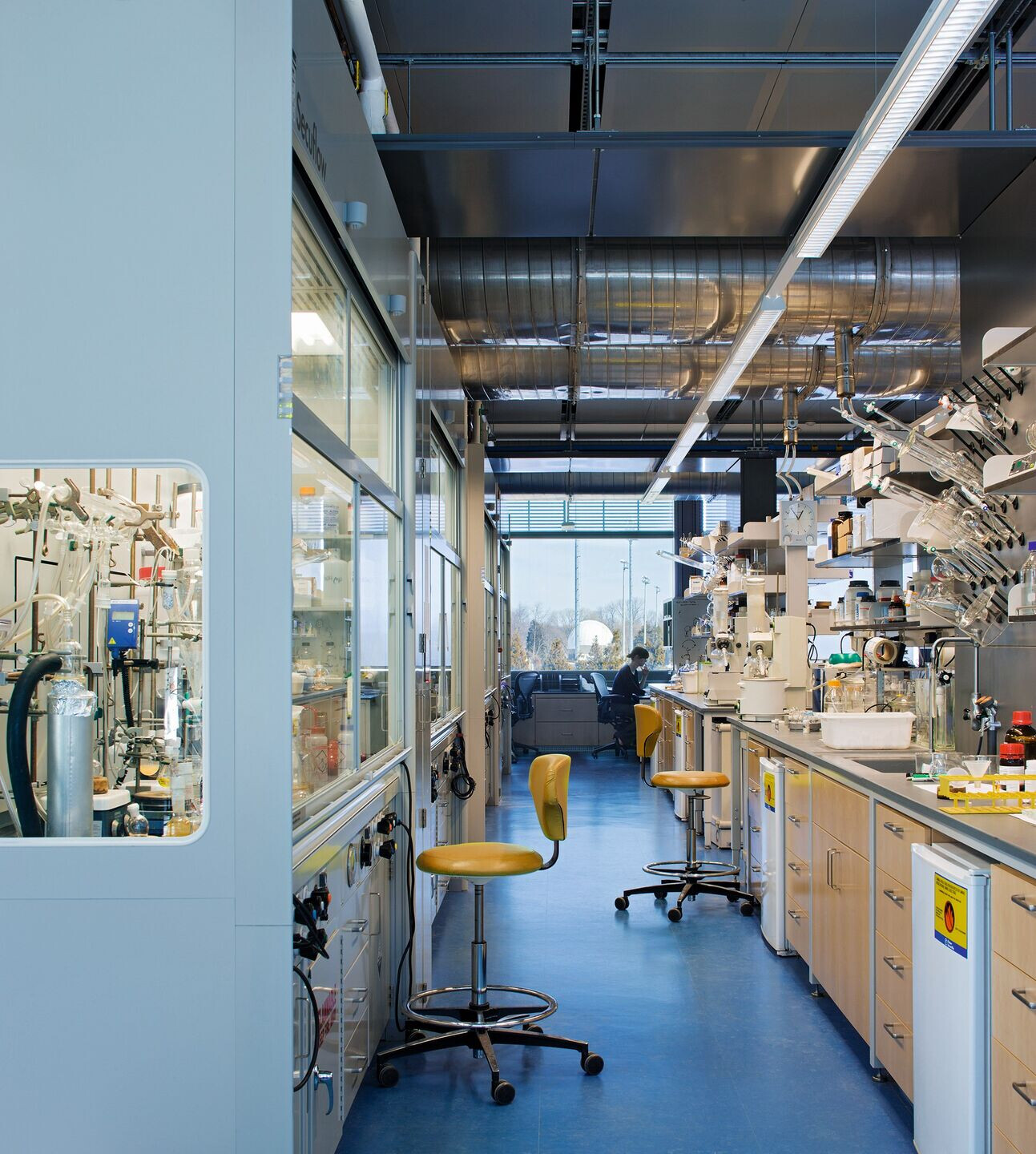

The building is designed to act as an incubator for the next generation of ideas and discoveries, integrating teaching and high-level research spaces in a facility which enhances interaction, collaboration and creativity. The design allows the main programmatic elements of faculty offices and laboratory research spaces to be expressed through a 75-foot high atrium serving as a centralised circulation, interaction and meeting space. The close proximity of professional and academic research spaces allows the facility to act as an incubator for the generation of new ideas and discovery of new drugs and cures, while its systematic layout will support flexible adaptation of workspaces as science instruction and research evolve.

We worked closely with laboratory planning experts to consider scale, environmental conditions and social engagement, arriving at a building which is future proofed, with a rigorous layout to support flexible adaptation of workspaces.

What materials did you choose and why?

A palette of granite, glass, powder-coated glazing system and sand-cast aluminium shading is accentuated in the highly-engineered and prefabricated façade system.

Manufactured offsite, the facade includes 2,100 individual high-performance glass lites, to allow significant daylight penetration and features automated shading devices and a highly-insulated design to lower active demand on mechanical systems. Offsite prefabrication also allowed for faster construction and less waste.

Team:

Executive Architect: Payette

Design Architect: Hopkins Architects

Lab Planner: Jacobs

Structural Engineer, MEP, Security, Acoustics, Fire, Facades, Lighting and IT: Arup

Landscape: MVVA

Code: RW Sullivan

Cost Consultant: Faithful + Gould

Contractor: Turner Construction

Photography: Warren Jagger