The project, now knowingly, displays two key themes; the pursuit of a practise of reverse marginalisation – a conscious reaction to the profession’s potential for a passive demise into the insignificant – and specifically what makes us matter, what makes us useful.

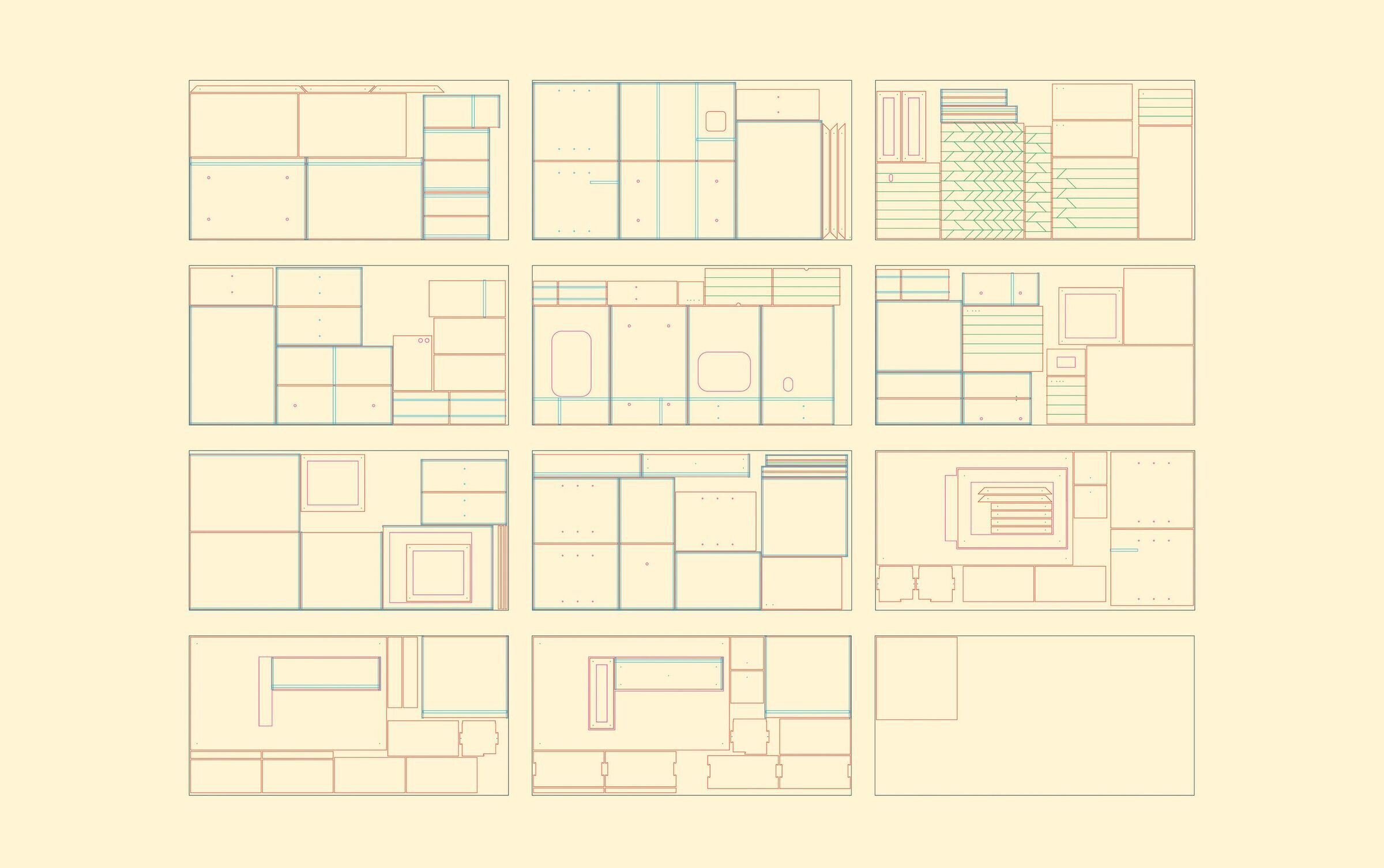

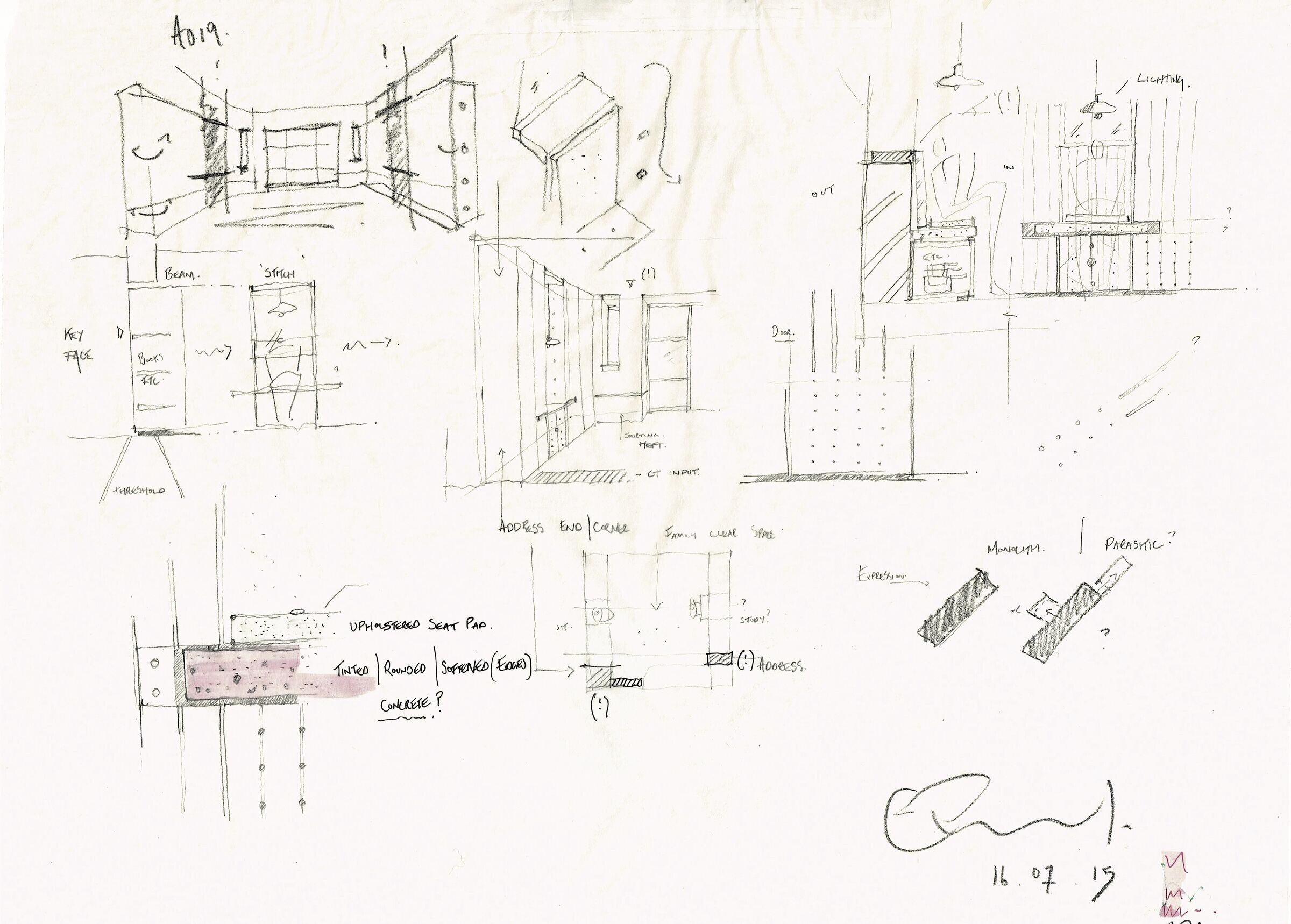

The second theme sees the continued exploration, questioning and evolving attitude to craftsmanship in a digital age. Here, each and every joint, element and mark-made was first three dimensionally modelled, tested and then further drawn for fabrication via automated CNC cutting – enabling absolute control, expression and accuracy. Physical 1:1 prototypes ensured a more precise understanding of scale so often hard to grasp in a purely digital environment.

Early interests stemmed from the origins of the rural kitchen and its ability to convey both the tough and utilitarian, and the beautiful – how a material might shape itself through continued use or how evening light soaks across a well-worn surface. Later explorations saw us refine our rules of engagement with the host; ensuring a melding of layers and an intent that that which was placed or inserted felt of the place and of equal qualitative merit – a palette of relatively humble and robust materials were elevated via various processes to enhance their base qualities.

Ergonomics, utility and formal hierarchy can be seen in the visually segmented kitchen station where use is suggested by surface material, the three articulated doorways where material application to the ziggurats and threshold depth denote importance.

For total clarity, we drew the entire project at 1:1 and continued to produce close to ten tranches of fabrication drawings. This included both the positive forms and the negative formwork; we drew, for automated cutting, close to twenty individual casts (thresholds, surfaces, wall panels, sinks), continuing to pour and strike the concrete ourselves also.

Clearly these methods result in a digital library for continued adaptation going forward, for ease of repair when revisiting, and perhaps most importantly, the reduction of waste to the sawdust created by the width of a drill bit.

There were of course failures, failures during casting, warped timbers, occasional delays and still a couple of minor defects that we are addressing – all of which had and have to be rectified and absorbed. Downsides that are easily outweighed by the ability to tailor precisely to context and the sense of closeness to the work, so rarely achieved via standardised routes. This is a close, intense and engaged way of making architecture.

Beauty

Beauty is so often difficult to define, although I believe it is seen as beautiful by those that use and live within this family home. Further moments continue inside much of the furniture via CNC carved inscriptions and extrapolations of project detail.

It is perhaps this extrapolation of the scars seen on the oldest timbers of the house, that anchor the project so successfully – lending an hard to define time of placement; a conscious melding of older, old,recent and new.

Innovative

For total clarity, we drew the entire project at 1:1 and continued to produce close to ten tranches of fabrication drawings. This included both the positive forms and the negative formwork; we drew, for automated cutting, close to twenty individual casts (thresholds, surfaces, wall panels, sinks), continuing to pour and strike the concrete ourselves also.

Clearly these methods result in a digital library for continued adaptation going forward, or for ease of repair when revisiting, and perhaps most importantly, the reduction of waste to the sawdust created by the width of a drill bit.

Beneficial

We all try to claim that our projects are beneficial – I suppose you really should ask those that live within the work – our hope, is that a room like this will lift, comfort and play host to many of life’s happier moments and that is all that we can hope for.

In a wider, professional context, we hope that other architects will grasp opportunities and position themselves away from such a subservient position of decreasing influence by taking greater risk and responsibility – in favour of such demonstrable reward.

Team:

1. CNC fabrication from CTA drawings and models by Cut & Construct

2. Fabricator of CTA designed hand turned elements: Nichols Brothers Wood Turners

3. Modern day marquetry steel inlay by Steel Dynamics UK

4. Brassware by Vola