Designed by Peter Pichler Architecture, the new Bonfiglioli Headquarters is located in Calderara di Reno on the outskirts of Bologna, Italy. The building is an expression of Bonfiglioli’s history and manufacturing know-how, something that is in part represented by the innovatory use of a custom continuous pleated aluminum mesh skin.

Established in 1956, Bonfiglioli is a global Italian company that manufactures and supplies a wide range of products, including gearmotors, drive systems, planetary gearboxes, and inverters. The company’s products are found across industrial automation, mobile machinery, and renewable energy sectors. The new HQ completes Bonfiglioli’s EVO project, the company’s largest industrial site in Italy with a huge production plant, green spaces, and research and development facilities. (The total area is 150,000 square meters — 1,614,587 square feet.)

“I think that our aim was to create an open building that connects people and at the same time has a radical approach towards sustainability with an intelligent geometry,” says Peter Pichler, Founder and Partner at Peter Pichler Architecture. “The building stands out as a recognizable landmark that both rises above and integrates itself with the surroundings.”

As a starting point, the design of the 6,200-square-meter (66,736-square-feet) HQ integrates the courtyard typology of the existing EVO masterplan buildings into the massing. “This courtyard houses a green garden on the ground floor and creates natural ventilation through a chimney effect,” says Pichler.

A pleated aluminum mesh skin that filters sunlight

Aligned with the sun, the Bonfiglioli HQ has two larger north-facing facades and two smaller south-facing facades (plus the sloped roof), a design that increases the amount of natural light (north) and reduces heat gain (south). “In response to local sunlight conditions, the building’s roof has been tilted, enlarging the north-facing facades to maximize workspaces with indirect natural light. At the same time, this reduces the south-facing facades, improving indoor comfort and saving energy,” says Pichler.

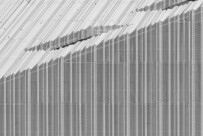

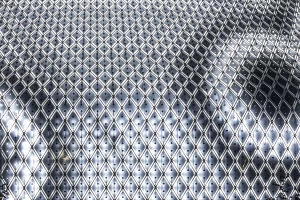

“The south-facing facades and roof of the headquarters are clad in a second skin made from a custom continuous pleated aluminum mesh, which filters intense light and ensures a comfortable indoor working environment,” says Pichler. “By incorporating this custom-designed mesh, the building optimizes natural light conditions while simultaneously reducing the need for excessive artificial lighting.” Temporary spaces such as meeting rooms are placed on the building’s south-facing sides.

This pleated aluminum mesh skin lends the building an almost dreamlike quality, while at the same time symbolizing Bonfiglioli’s industrial prowess. “The pleated facade geometry is inspired by Bonfiglioli’s gearmotors while the aluminum mesh recalls the shavings that are produced daily as a byproduct of the company’s supply chain,” explains Pichler.

“The facade is an architectural project designed with the logic of the orientation of the building,” says the architect. In essence, “light is filtered on the building’s south-facing side, while the transparent facades on the north-facing side maximize light."

“The installation process involved careful coordination between the construction team and specialized technicians to ensure the correct positioning of the pleated mesh, maintaining both its aesthetic appeal and functional purpose,” says Pichler. The interplay between materiality and efficiency, form and function, is key to balancing the building’s aesthetic and practical design. “The main design goal was to create an efficient and functional office building that represents the identity and cultural values of Bonfiglioli,” says the architect.

The Bonfiglioli HQ utilizes two particular facade systems: mullion-transom and double-skin. Mullion-transom facades offer versatility and allow for a greater level of creative freedom, as demonstrated in the use of large panes of glass with extremely slim special profiles. The construction is based upon the connection of vertical mullions and horizontal transoms. Double-skin facades are aesthetically pleasing — the use of a pleated aluminum mesh skin hides a primary inner facade. This second skin works to enhances the building’s overall aesthetic appeal while improving its indoor climate.

Exoskeleton architecture

“The structural concept of the building is based on the perfect integration of architectural intent and design. This is particularly evident in the exoskeleton which is one of the main structural components of the building — it is an element that strongly characterizes the architectural concept,” says Gianmichele Melis, Associate Director at ARUP. (ARUP managed the project’s structure & MEP and electrical engineering.)

Pichler adds that the exoskeleton “provides maximum comfort to the internal spaces and optimizes maintenance.” The design team took great care to make sure the building’s internal spaces can be used flexibly — with no pillars, it is the facade that bears the entire weight of the structure. The steel exoskeleton angles outwards at ground floor level, rising vertically and transitioning into the roof, thereby distributing the building’s mass. Pushing the boundaries of contemporary steelwork, the exoskeleton structure ensures future flexibility with open, column-free interior spaces. Moreover, its visible north-facing parts are covered with the pleated aluminum mesh, thereby connecting all sides of the building with a coherent design language.

Workspace design

The building’s interior benefits greatly from the exoskeleton design. Pichler describes the building’s inside as “a testament to modern workplace design, fostering connectivity and collaboration.” The interior is both clean and uncluttered, a serious-minded, physical workspace whose layout is carefully arranged. Two sculptural spiral staircases are crafted from steel and wood; on the third floor, a bridge spans the internal courtyard to connect departments and further facilitate movement, workflow, and communication.

The building’s design places an emphasis on health and well-being. It incorporates green spaces and maximizes indirect natural light to enhance the working environment. The distinctive sloped roof incorporates six south-facing terraces, their depth and position uniquely enhancing the building’s overall appearance. With terraces on each level, they offer serene outdoor spaces, providing the opportunity to pause, take a break, or have informal meetings. These terraces improve the overall quality of the office spaces and provide views towards the Santuario Madonna di San Luca (the Sanctuary of the Madonna of San Luca) and the city of Bologna. The pleated aluminum mesh that surrounds the terraces increases the character of these spaces.

Sustainability

“Bonfiglioli’s new headquarters is not just a place of work but a testament to the potential of sustainable design in the industrial sector,” says Pichler. The advanced architectural design reduces CO2 emissions, helping the building to achieve energy self-sufficiency. The building’s design also incorporates circular economy principles ensuring it can be adapted to the evolving needs of the client. Bonfiglioli’s EVO site is powered by a 3 megawatt (MW) peak power photovoltaic plant mounted on the new production plant roofs and the awnings of the staff car park. The new HQ is conceived as a nearly zero-energy building (NZEB). Its construction includes geothermal heat pumps and radiant ceilings (that use radiant heat transfer to warm a room).

More than just a place of work, the new Bonfiglioli HQ is a testament to sustainable design and intelligent geometry. Its unique second skin — the pleated aluminum mesh — sets the building apart. From a distance, it appears like a wonderfully surreal mix of architectural realism and fantasy.