The IT Research facility is a smart reworking of old that showcases new, cutting-edge virtual reality (VR) technology for students and the broader university community.

The project is part of a large relocation of the Faculty of IT from the Caulfield campus to the Clayton campus, and transforms two disused lecture theatres in the university’s engineering precinct. Merging together, the theatres give rise to a series of spaces designed for purpose-built, 3D motion capture, and relevant support areas.

The core idea was to create high tech environments to support the faculty’s VR research, in keeping with the ideals expressed in the Monash University Masterplan. We took this a step further, by making the act of research visible through thoughtfully conceived design.

Our design punctuates the facade with a series of large, square windows to the north and west. Rather than simply looking at a glorified façade, passersby are invited to peer into the windows, which reveal the VR zones and research in action, akin to a shopfront display.

The fenestrations are strategically placed along a primary circulation path, after analysing the way people move around the site. For example, the west side attracts the most traffic, so the VR spaces were placed on this side. Metal shroud shopfront windows signify the new work and enable ‘Research on show’, also in line with the University’s Masterplan.

The design process included a careful study of existing VR reality environments, including a PHD research space and existing VR space at Caulfield as well as the biomechanics research space at Deakin University.

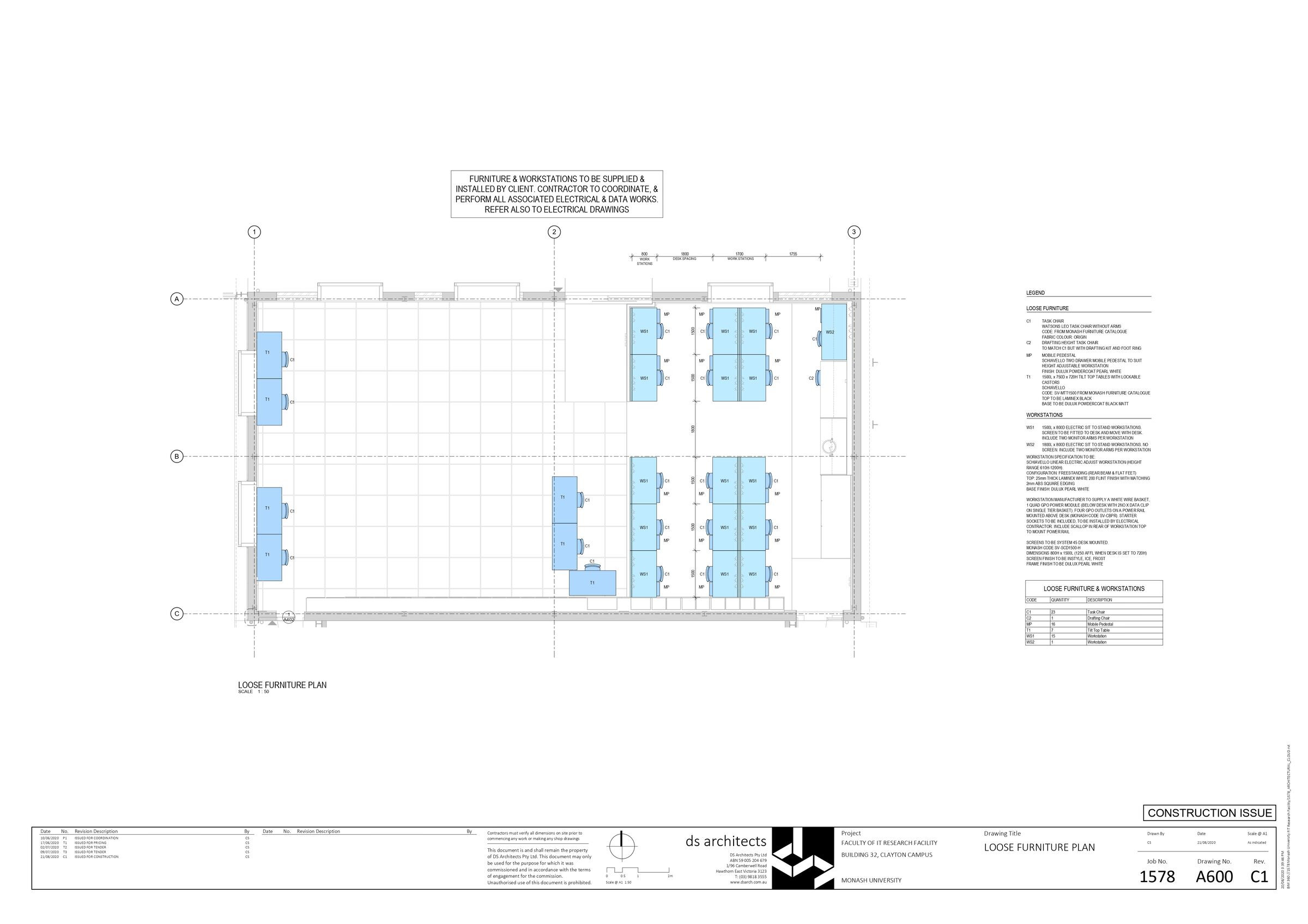

After experimenting with many different design iterations, our response was to design a large virtual reality testing zone to the west of the building. This could be split into four smaller zones, providing the flexibility to create different environments required to conduct a mix of research and data collection.

The building comprises:

New dedicated research space

Large 9m x 9m VR testing zone to the west end of the building

Open plan technical workspace for 15 people

Office space

Kitchen amenities.

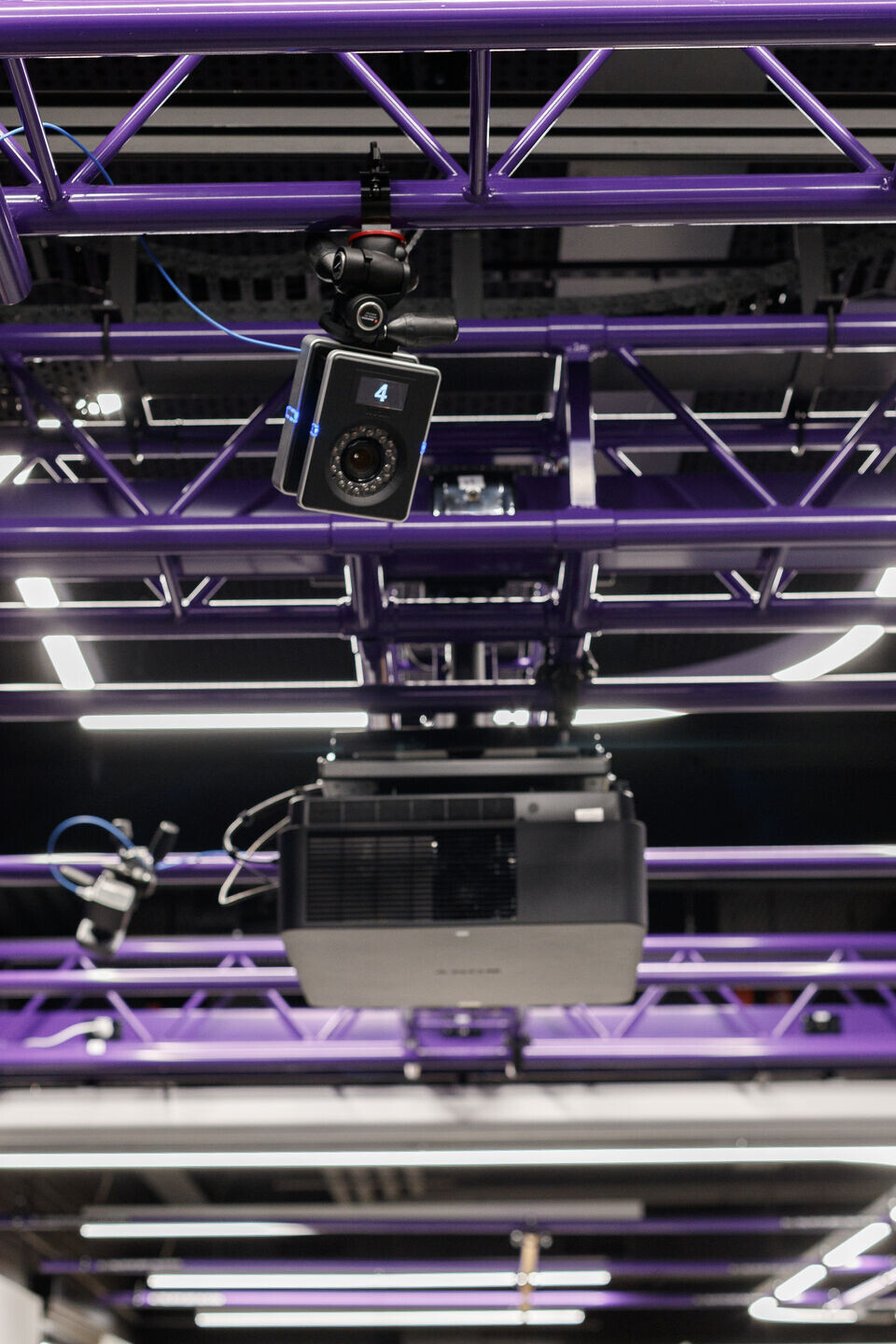

During construction, the tiered concrete lecture theatres were stripped out and half of the ceiling above the VR zones was fitted with highly specialised overhead motorised grids. Attached to the grid is a series of mounted motion tracking cameras, as well as provision for speakers, projectors, light and additional tracking cameras.

Accordingly, the grids required precise and additional bracing and bracing points. This was important to ensure that they are stable while the cameras are in use for precise in motion capture. The grids can also be brought up and down to rearrange the cameras, to suit research requirements.

As demands on the building also change, the research facility is future proofed. The open plan office space is designed to allow the refit of additional VR space, which can flex and grow with the facility. Colour and modern features include delicate detailing of a new trellis for planting, while for occupants, the new windows provide access to natural light lacking in the former theatres.

As much as this project is about the future, it also pays homage to the past. The brickwork façade was treated carefully and deliberately with a heritage approach, and retained to not only minimise waste, but also to bring a unique design element to the project. This is highlighted by deliberate, staggered brick detail showcasing previous doorways, signifying the past life of the building.

Together, the old and new elements create a building that sparks conversations and interest by those who walk by. Located within the engineering precinct also means greater opportunities for cross-disciplinary interaction between the faculties, a third ideal of the masterplan.

At heart, this is a building that delivers on the university’s vision to be a leader in education and research. In doing so, we are proud to contribute a building at the forefront of the university’s future, which is supporting the best and brightest technology minds in Australia.

Materials Used Section 16a:

Floors:

HydroControl HydroSton H50 - Permeable Paving (PV)

Concrete Paving, Concrete Paving (CPV), Concrete Footpath, Exposed concrete in front of door, Exposed concrete

Walls & Linings:

Brickwork - BRF, BRR, Existing External Brickwork (BRX), Mortar

Stainless Steel Trellis - Dulux Fluoroset Xtreme Aluminium SHS and fixing plates, Mesh Anodised

Doors:

Dulux Powdercoat Fluoroset Xtreme- Aluminium door frame (PC1), Alumnium frame for door leaf, Shroud (PC1), Cover for auto door operator (PC1), Aluminium frame for sidelight (PC1), Shroud, Door Frame

Dulux - Door Leaf - external side, Door Leaf - internal side

Glazing Framing & Film:

Dulux Powdercoat Fluoroset Xtreme- Glazing Adaptors, External Window Shroud (PC1)

Internal Aluminium Windows / Shrouds, Safety Decal

Roof:

Colorbond - Roof Sheeting, Ridge Capping, Gutters, Rain Water heads (RWH), downpipes (DP), Parapet flashing and capping

Dulux - Existing downpipes noted to be painted on the drawings

Mechanical:

Dulux Powdercoat Duratec Zeus- Roof Cowls, Screen Around Condenser Unit On Roof

Dulux - New Pipework

Colorbond - Covers To External Pipework And Cable Trays

Electrical:

Colorbond - Covers To External Cable Trays

External Wall lights (W1)

Materials Used Section 16b:

Floors:

Troika - Dirt Barrier Mat

Interface - Equilibrium II Carpet Tarkett - Vinyl Sheeting VS1 Tarkett Primo Premium, Highlight Welding Rod iQ Surface, Vinyl Sheeting VS2 Tarkett Primo Premium, Welding Rod iQ Surface, Vinyl Sheeting VS3 iQ Granit SD Anti- static, Welding Rod

Walls & Linings:

Dulux - Internal exposed brick, Existing Steelwork, Plasterboard feature paint colour (PF1), Flush Plasterboard Boxing To Mechanical Fan Coil Units And Exhaust Fans

Dulux Powdercoat - Aluminium plate to P1 wall (AP1)

ITE - Curtains 500gsm wool-fire retardant

Track (CTK)

Ceilings:

Perforated Plasterboard (PP)

Dulux - Existing Steelwork, New Steelwork

Skirtings:

Armstrong - Vinyl 150mm Flat vinyl skirting

Windows:

Sapphire Aluminium - Internal Aluminium Shroud / Reveals (AF1)

Dulux Powdercoat Fluoroset Xtreme - Glazing Adaptors

Blinds:

Mermet - Sheer M Screen 5% Openness, Blockout Plaza Plus

Dulux Powdercoat - Bracket, Fascia and Endcap, Bottom Rail

Joinery:

Laminex - Tea Point Benchtop (LM1), Splashback (SB), Concealed Shelves, Carcass, Kickboard, Kicker

Woven Image - Acoustic Panel cupboard fronts (EP1)

Dulux Powdercoat - Trim to Acoustic Panel, Perforated Metal sheet behind Acoustic Panel, Perforated Metal Sheet Behind Acoustic Panel, CHS, Brackets And End Caps

Megasorber - Comms Cupboard Insulation

Screw fixings for Acoustic Panel Cupboard Fronts, Fixings

Motorised Grid:

Dulux Powdercoat - Space truss and adjustable pipes Alphatec, Hanging rods, Pulley, Winch, Wire Ropes, Energy Chains, Cable Duct

Power and data outlets, Motor control cabinet

Electrical:

Dulux Powdercoat Cable Trays - Mounted to brickwork, Mounted to underside of perforated plasterboard ceiling

Dulux Powdercoat Lights - Suspended Linear lights L1, L2, L3, LED1 Light, LED2 light, Skirting Duct

Dulux Fluoroset Xtreme - LED3 light

Emergency Lights, Exit Lights, Power And Data Outlets On Skirting Duct, GPOs at high level, WAPS and security cameras, Access Control

Mechanical:

Dulux Powdercoat - Return Air Grilles, Supply Air Grilles, HHW, CHW Pipework, Cabletrays, Ductwork

Fire:

Speakers And Smoke Detectors.