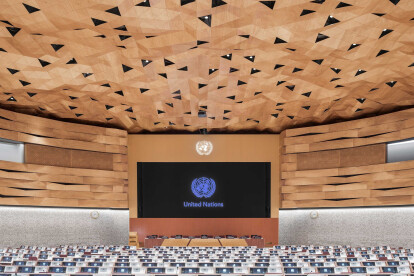

Architect Giampiero Peia, owner of the Peia Associati firm, presents the new Assembly Hall at the United Nations in Geneva. The project has just been completed and inaugurated with an institutional ceremony behind closed doors.

This is the New Hall of the Plenary Assembly of the UN in Geneva, inaugurated the 12th of November 2019, in the presence of Qatar's Minister of Foreign Affairs H.E. Soltan bin Saad Al-Muraikhi, of the Ambassador of the mission of Qatar in Geneva H.E. Ali Khalfan Al-Mansouri and the new UN generaldirector of Geneva Ms. Tatiana Valovaya.

Sheikha Mozah (Queen Mother of Qatar) has already honoured the new Hall with an official visit the of return from the Climate Action Summit in New York at the end of September.

This project was funded by the state of Qatar as a symbol of dialogue, détente and values of the country's culture in the world.

For the first time an Italian architect designs and implements an important work for the United Nations.

The work is a complicated machine that encompasses design culture and diplomacy. An ambassador project of a culture that presents itself in a global scenario multiplying and reinterpreting the value of Qatari tradition, culture, calligraphy and landscape through contemporary materials, technologies and languages. Peia Associati has chosen to give shape to this work with a strong contribution of Italian design. The project counts on the support of the AI Group for the engineering and the involvement of numerous Italian companies: the general contractor is CCM while for furnishings, finishes and lights participated Matteo Grassi, Wood-Skin, FLOS, Casalgrande Padana, Wallpepper. Partners include other European and international companies such as Taiden/Media-Vision, Wilkhahn and Krion/Porcelanosa.

The result is a room that stands as the ideal model for future UN rooms equipped with the best Audio-Video technology as well as inclusiveness, ergonomics and accessibility.

The first UN room with 60% of the seats usable by people with wheelchairs, the first with a Signs translation booth designed with technology specifically dedicated to sign interpreters (for deaf-mutes), the first in the world with a plant of artificial Circadian light that allows to balance the human biological clock aligned to the solar cycle.

And it is also the only room of the UN to have however a contribution of Natural light with sight on the park, the lake and towards the Alps and Mont Blanc, as a daily reminder of the climate change and the environmental emergencies of the planet. Through the inverted upside down perspective, the concept represents the Dune desert of the giant dome and the sky and the stars are all the nations on the floor.

ABOUT WOOD-SKIN

WOOD-SKIN was founded in 2013 in Milan to help architects and designers around the world bridge the gap between digital representation and architectural feasibility.

The patented WOOD-SKIN® process makes rigid surfaces flexible and flat surfaces three-dimensional, giving volume, dynamism and “soul” to a multitude of materials that industry and technology have traditionally relegated to the two-dimensional state.

We are a heterogeneous company made up of architects, designers, and engineers united by a shared passion and particular attention to materials, details, digital manufacturing and software.

WOOD-SKIN is a brand that offers innovative products for architecture using digital manufacturing technologies. The panels are made by joining 2 sheets of rigid material with a textile core.

The designer can define the 2 external layers by choosing from a wide range of materials, thanks to virtuous partnerships with brands such as Fenix, Alpi, Almeco, Forescolor and many others.

Through our computational design department, we support architects, designers and general contractors with the right tools at every stage of the project, from the development of the idea to its final realization. Our 3 systems Mesh Sheets, Fold Panels and Tailor Made, customizable to the millimeter and able to meet all design requirements, make it possible to vary geometric patterns, dimensions, and finishing materials.

The software, an integral part of the WOOD-SKIN® patent, allows us to tessellate the surfaces of the 3D model in order to produce the precise geometries which, joined by fabric hinges, recreate the exact configuration of the digital design without the use of heavy and expensive structures. Since the process can be studied and tested prior to installation, we are able to produce optimized elements and with minimal waste of material.

With years of experience in the construction of three-dimensional surfaces, today we are able to offer architects and builders a multitude of wall and ceiling cladding products, which can be shipped flat all over the world and installed directly by local workers thanks to a simple assembly system and the absence of a substructure.