World of Volvo is a joint venture between Volvo Cars and the Volvo Group. This new 22,500-square-metre experience centre is located in central Gothenburg, the city where Volvo’s journey began in 1927. Designed by Henning Larsen, the project integrates computational parametric design with mass timber. The impressive main structure, made from glued laminated timber (glulam) and cross-laminated timber (CLT), forms three majestic tree trunk-like columns arranged in a mathematical pattern. Spreading outwards, these columns support the roof’s entire mass.

Allemansrätten: the right to roam

World of Volvo is designed around the Swedish concept of “Allemansrätten”, a right to roam, to access public or private land while showing consideration for nature and people. Its expansive circular structure encourages visitors to create their own journeys, indoors and outdoors. The building’s design embodies the regional landscape, in form and materiality. The interior tree-like columns envelop visitors in an enchanting forest-like canopy. The exterior mountain-like accessible roof allows people to wander and explore. Henning Larsen’s concept for World of Volvo brings an innate piece of Swedish nature to the centre of Gothenburg.

“The largest and most complex timber building in Scandinavia”

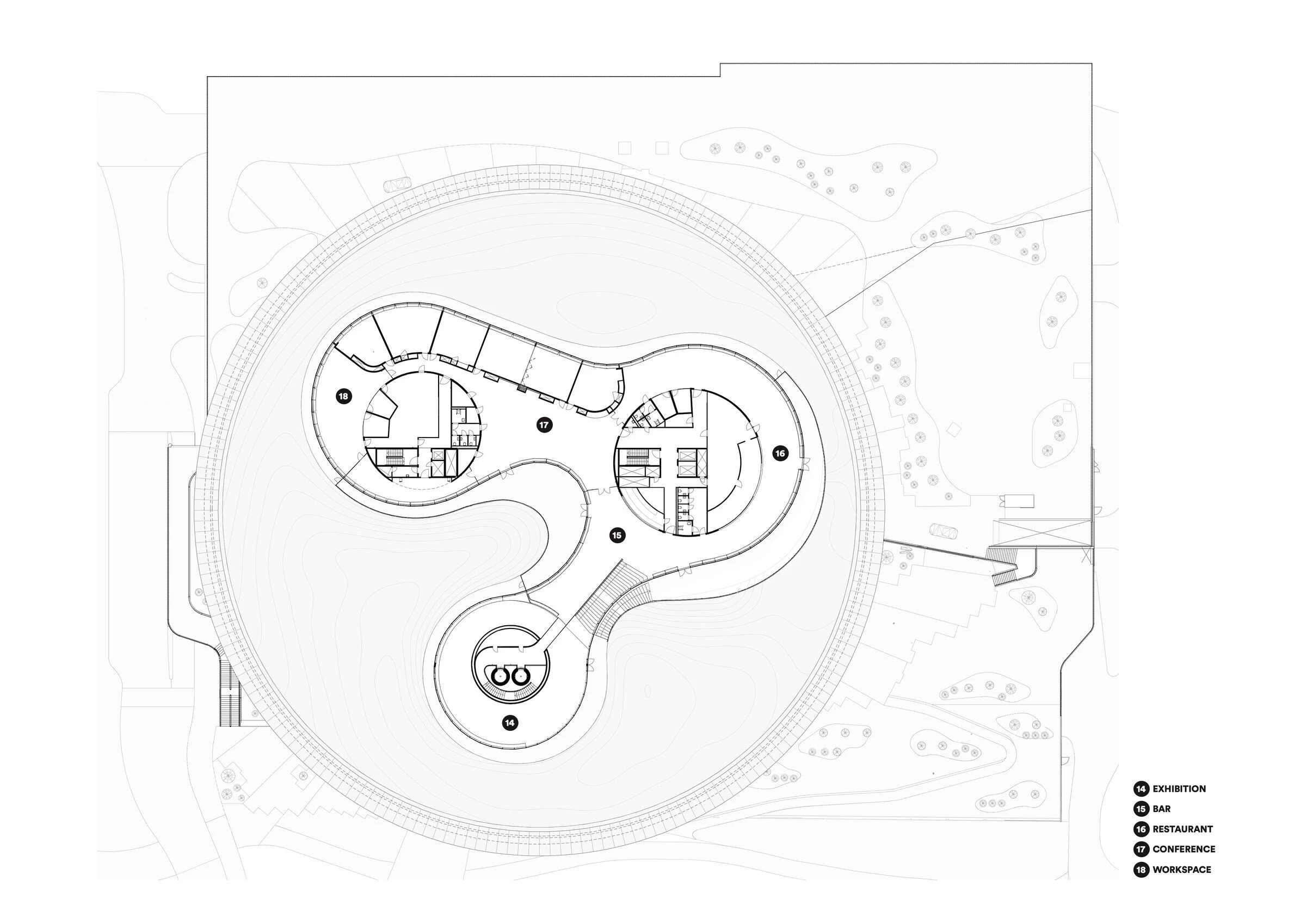

World of Volvo is both an exhibition centre and meeting place. An interactive exhibition takes visitors on a journey through Volvo’s history, innovations, and future visions. The centre also provides spaces for cultural events, meetings, and conferences. To support the client’s functional requirements for the building, Henning Larsen worked with engineers to achieve large expanses without structural interruptions. Martin Stenberg, Associate Design Director at Henning Larsen, says: “There’s a strong link between organic materials and organic forms. We have found structural inspiration from nature and the two go hand in hand with great result.”

Austrian timber engineering and construction company WIEHAG describes World of Volvo as “the largest and most complex timber building in Scandinavia.” The building has a diameter of 110 metres. Its glulam beams and columns are constructed from PEFC certified European spruce; the floors, walls, and roof slabs are made using locally sourced PEFC certified spruce CLT. The building’s complex architecture demanded a high degree of precision. WIEHAG explains that the company’s computer-controlled manufacturing system “enabled the imposing, curved components to be precisely cut and prefabricated.”

Stora Enso, a manufacturer and provider of renewable materials, provided the project’s CLT. It describes World of Volvo as a “massive 5,000 piece wooden puzzle box [that required] only 20 minutes per puzzle piece to complete, with just two cranes and two crews in 28 weeks.” Stora Enso’s in-house software was used to coordinate the installation, ensuring that every crew member knew exactly where each piece of the puzzle would fit.

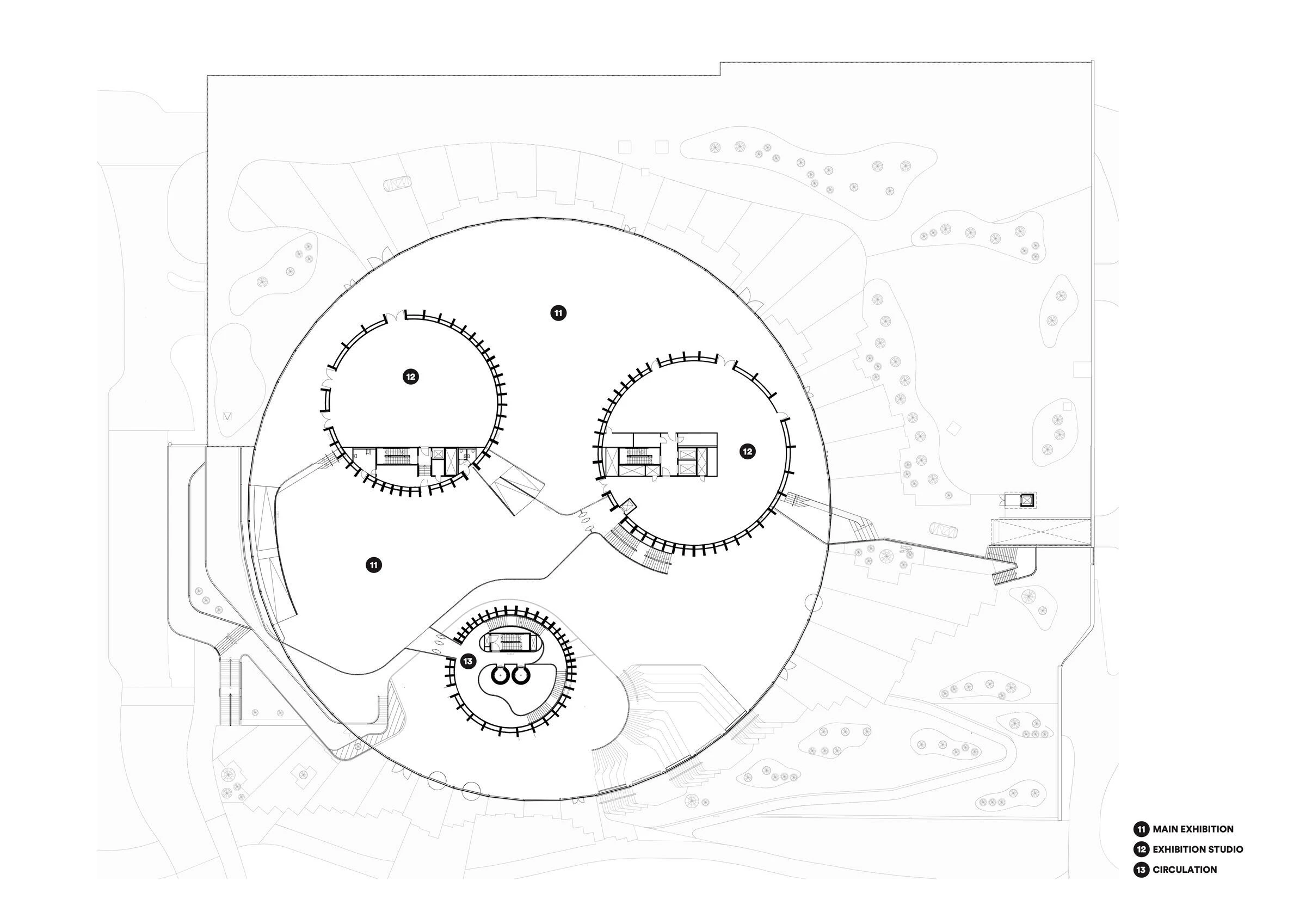

The three tree trunk-like columns are load-bearing and contain specific functions that relate to the operation of the building: One column houses the main circulation, providing access to each floor via 360-degree glass lifts. The other columns house exhibition dark spaces.

On the building’s periphery, 51 glulam columns support the roof beams and bear the weight of the cantilever which extends ten metres outwards from the facade.

World of Volvo’s exacting design tested the boundaries of large-scale timber construction. The project’s use of timber represents a traditional way of building in the Scandinavian context, together with a decidedly cutting-edge approach.

A digital workflow

When designing World of Volvo, Henning Larsen developed a digital workflow, incorporating its expertise in computational and parametric design. The process involved creating a script that aligns with the structural logic of the components while considering the manufacturing process of the wood beam elements. An understanding of the manufacturing process allowed for the creation of an optimised structure that minimises resource use without compromising on the concept.

Early integration of a flexible computational workflow made it possible to experiment with the building’s height, the geometry of the roof, the radius of the three inner cylinders, and the number of columns. The structural implications of these different choices were evaluated in collaboration with the manufacturer.

A timber-steel hybrid solution

The 654 large glass panels in World of Volvo’s floor-to-ceiling facade bathes the interior in natural light and merges the structure with nature. The glass facade was constructed by Lindner Scandinavia, using a timber-stick facade system made with locally produced glulam. While World of Volvo is predominantly a wood structure, its facade makes use of horizontal steel supports. The steel supports are directly attached to the glulam frame, creating a timber-steel hybrid solution. The facade therefore appears more transparent when slightly distanced from the frame. In addition, the supporting structure is less prominent due to the use of slender steel profiles.

An eco-friendly base

A five-storey, 45,000-square-metre car park beneath World of Volvo is owned by Göteborgs Stads Parkering. Emphasising sustainability, it is constructed from eco-friendly green concrete. Approximately ten percent of the car park’s 1,500 parking spaces have electric chargers. It is from this solid yet eco-friendly base that World of Volvo rises.

World of Volvo is certified LEED Gold and WELL Building Standard Gold.