In Kristiansand, Norway, the “Lumber 4” commercial and office building is characterised by its distinctive green concave facade elements. Designed by Oslo-based Oslotre, the six-storey mass timber building features five upper office levels and a recessed, circular ground floor, creating a sense of lightness. Oslotre also served as the project’s interior architect and timber structural engineer.

Making extensive use of timber

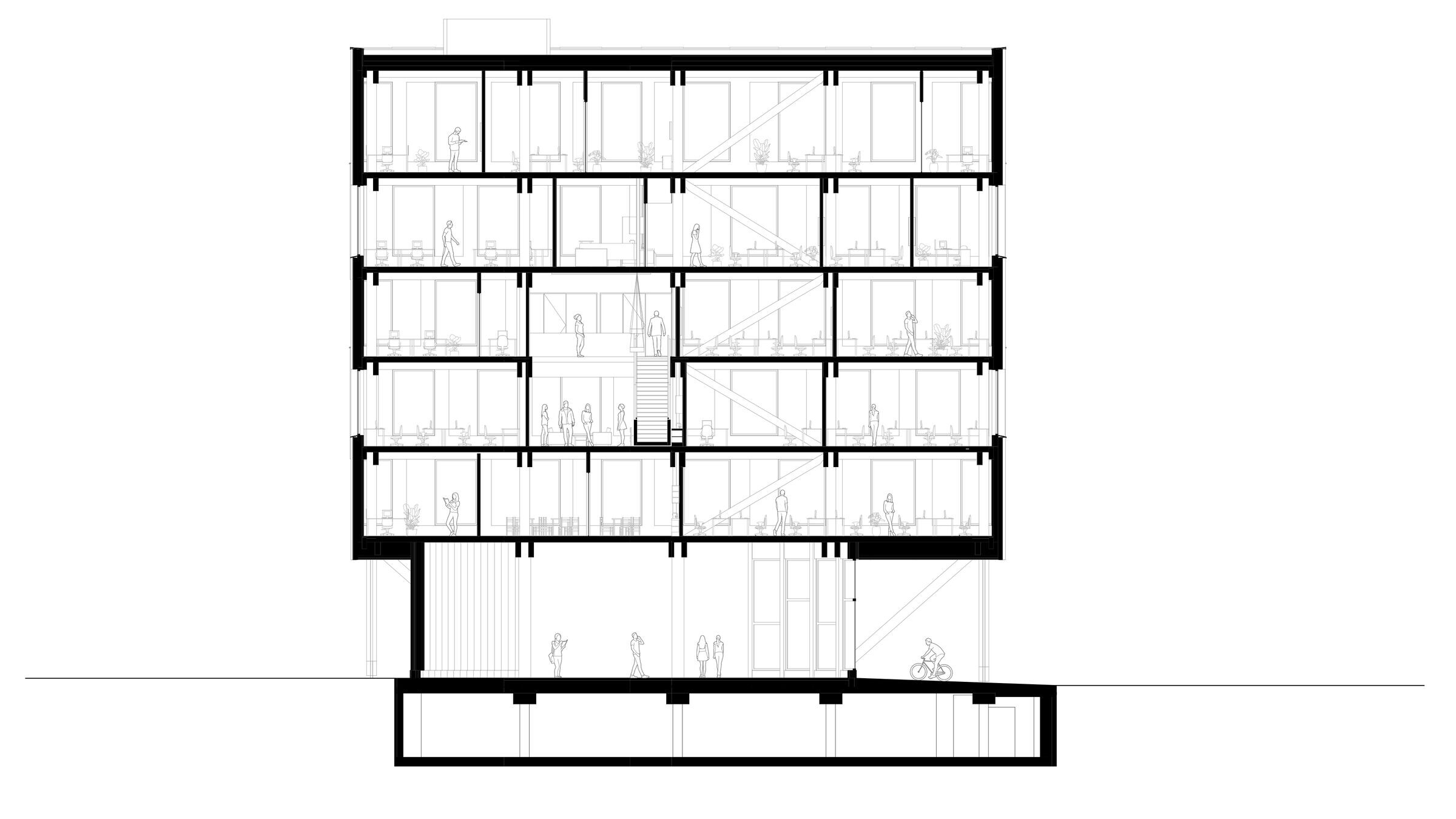

Lumber 4 is part of Lumber Teknopark, an energy and offshore wind centre in the Vågsbygd district of Kristiansand. Lumber, a neighbourhood in Vågsbygd, has a historical connection to the timber industry through logging and plywood production. A mass timber building, Lumber 4’s load-bearing system is constructed with spruce glulam beams and columns. Its floors are constructed using Timber-Concrete Composite (TCC) slabs, made up of two-thirds cross-laminated timber (CLT) and one-third concrete. This creates a slim and efficient system that spans long distances, as well as addressing fire and acoustic requirements. All insulation is made from wood fibre, while the cladding is made of fire-resistant heartwood pine. The ground floor’s diagonals improve vehicular access around the building (there is a car park beneath the structure) and help to absorb compressive forces.

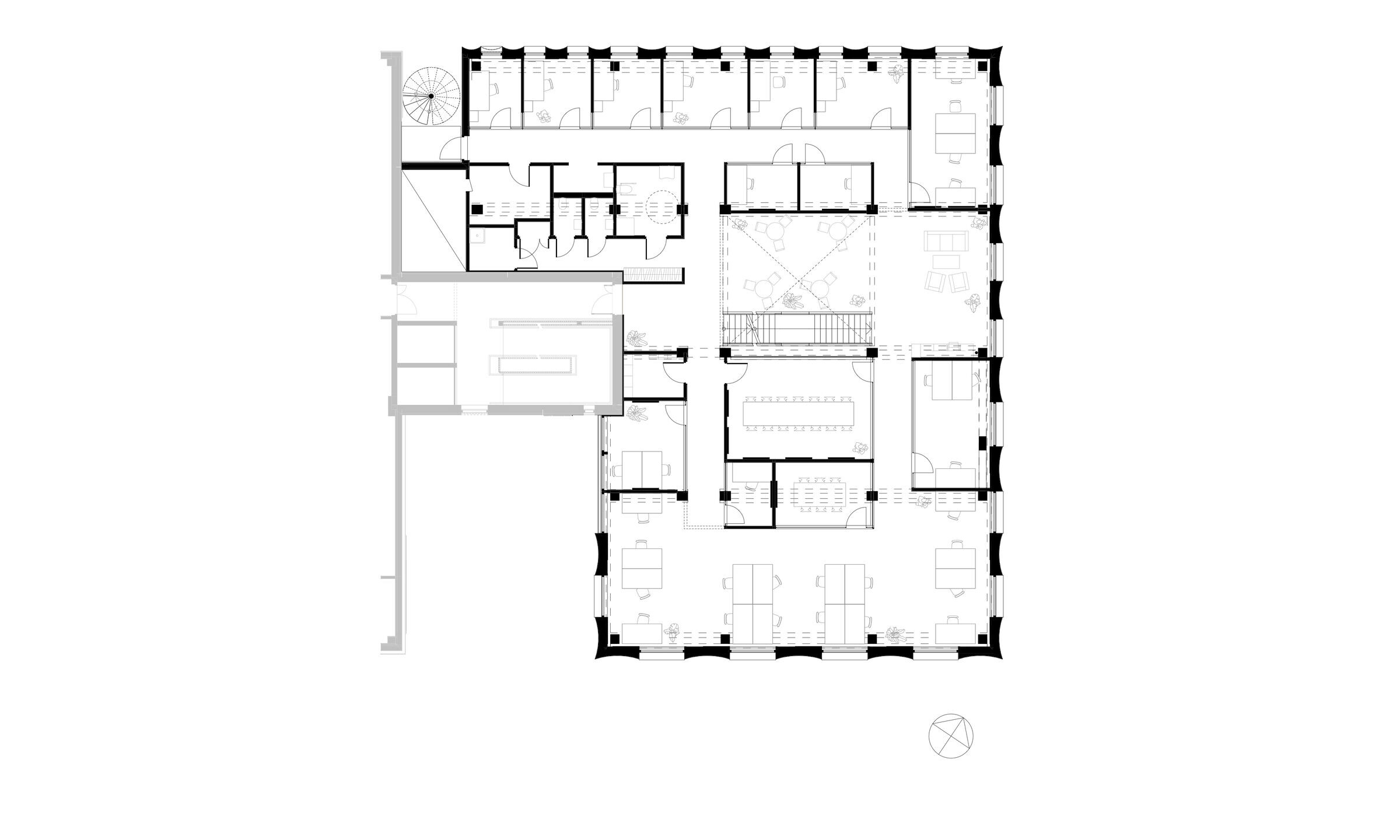

A concrete service core from an adjacent building contributes to Lumber 4’s lateral stability, allowing for an open and flexible office space design. The core’s lift and stairwell are shared by Lumber 4.

A distinctive facade

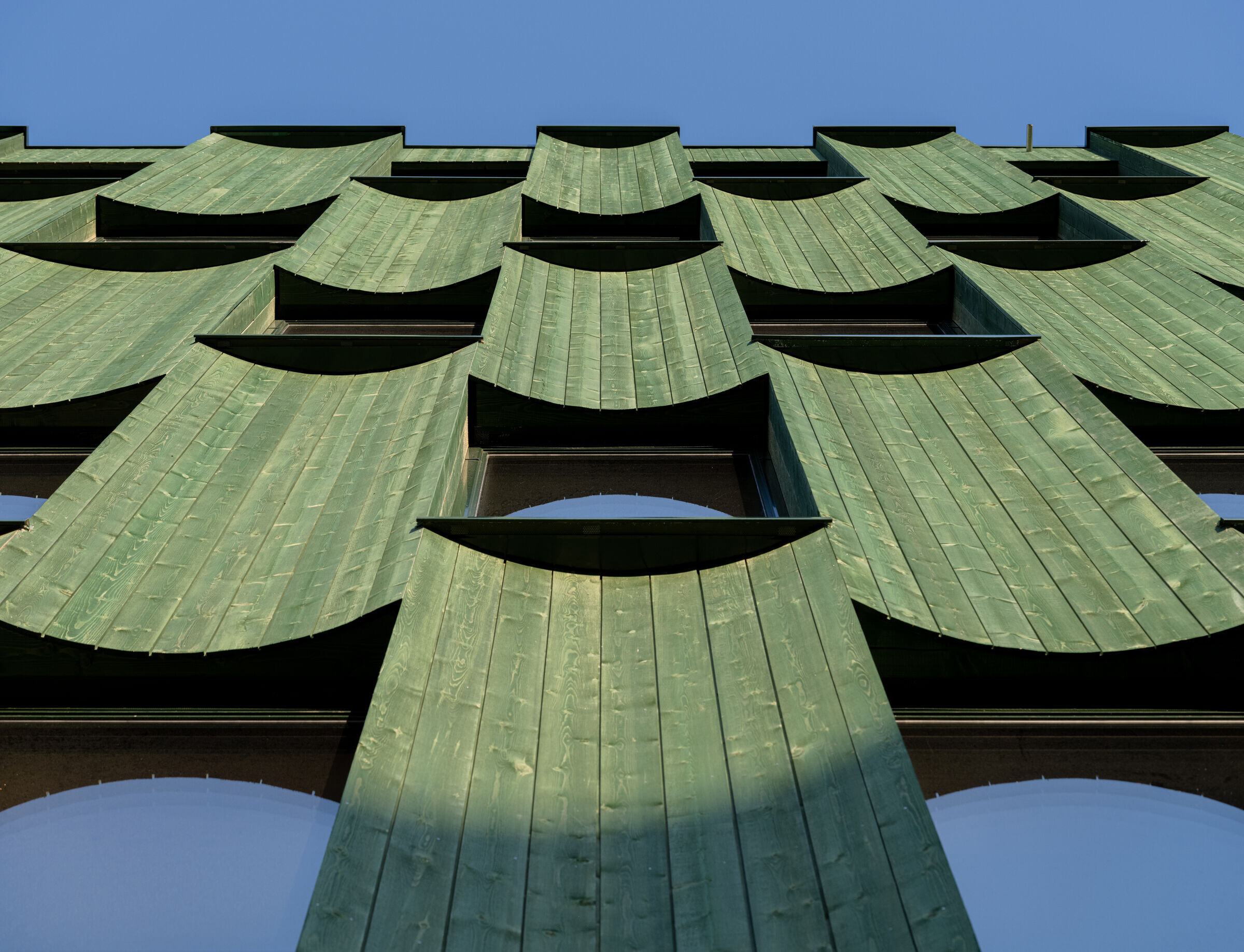

A distinguishing feature of Lumber 4 is the building’s concave facade elements. The facade consists of green-painted, fire-resistant heartwood pine panels fixed onto prefabricated curved battens. Straight eaves above each curved element cast a crescent-like shadow on the panel, augmenting the facade’s three-dimensional aspect. The green paint will eventually weather and grey with age, leading to a facade with lighter and darker curved sections.

The building’s ground floor is painted in a subtle green, while its bracing columns remain exposed. Three pine trees, planted as part of the landscape design, allude to the wood used in the project.

Wood on the inside

The interior walls are mainly clad in white stained spruce panelling, contributing to cooling in warmer months and heating in colder months. A double-height atrium, located between the third and fourth floors, features a lounge area and a staircase made of CLT that connects the two floors. The upper part of the staircase rests on a glulam beam and the lower part hangs from supporting struts, reducing vibrations.

Wood wool acoustic panels are used in concealed service areas and meeting rooms, while visible ventilation ducts are painted in a light beige colour, blending with the interior’s wood palette. Large floor-to-ceiling windows open up to waterside views and provide ample natural light.

The detailed planning and construction of Lumber 4 was completed in just twelve months. “Lumber 4 has demonstrated that it's possible to construct competitive timber buildings when compared to similarly-sized technical standard concrete and steel structures. The building was 90 percent leased upon completion,” says Oslotre.