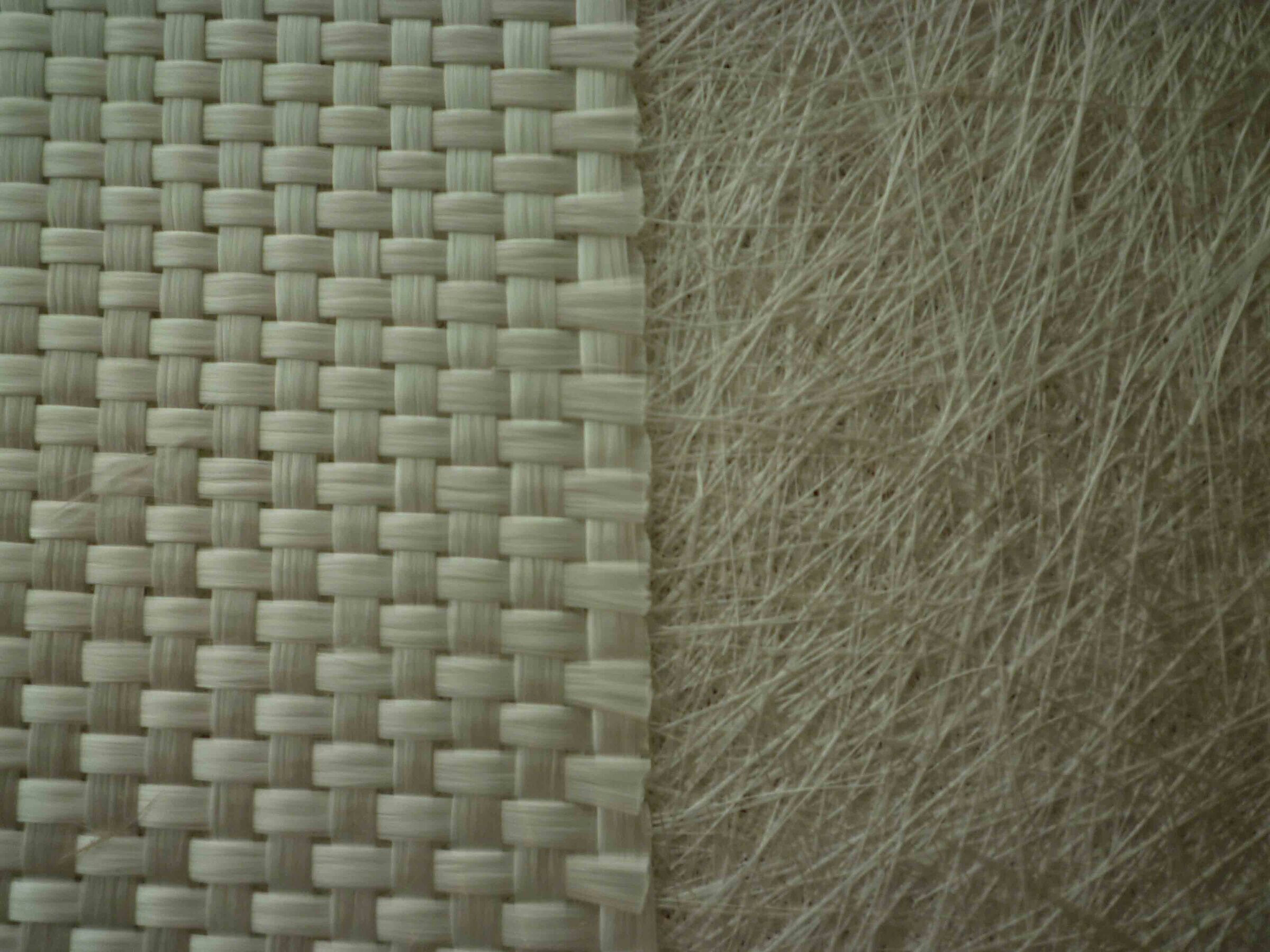

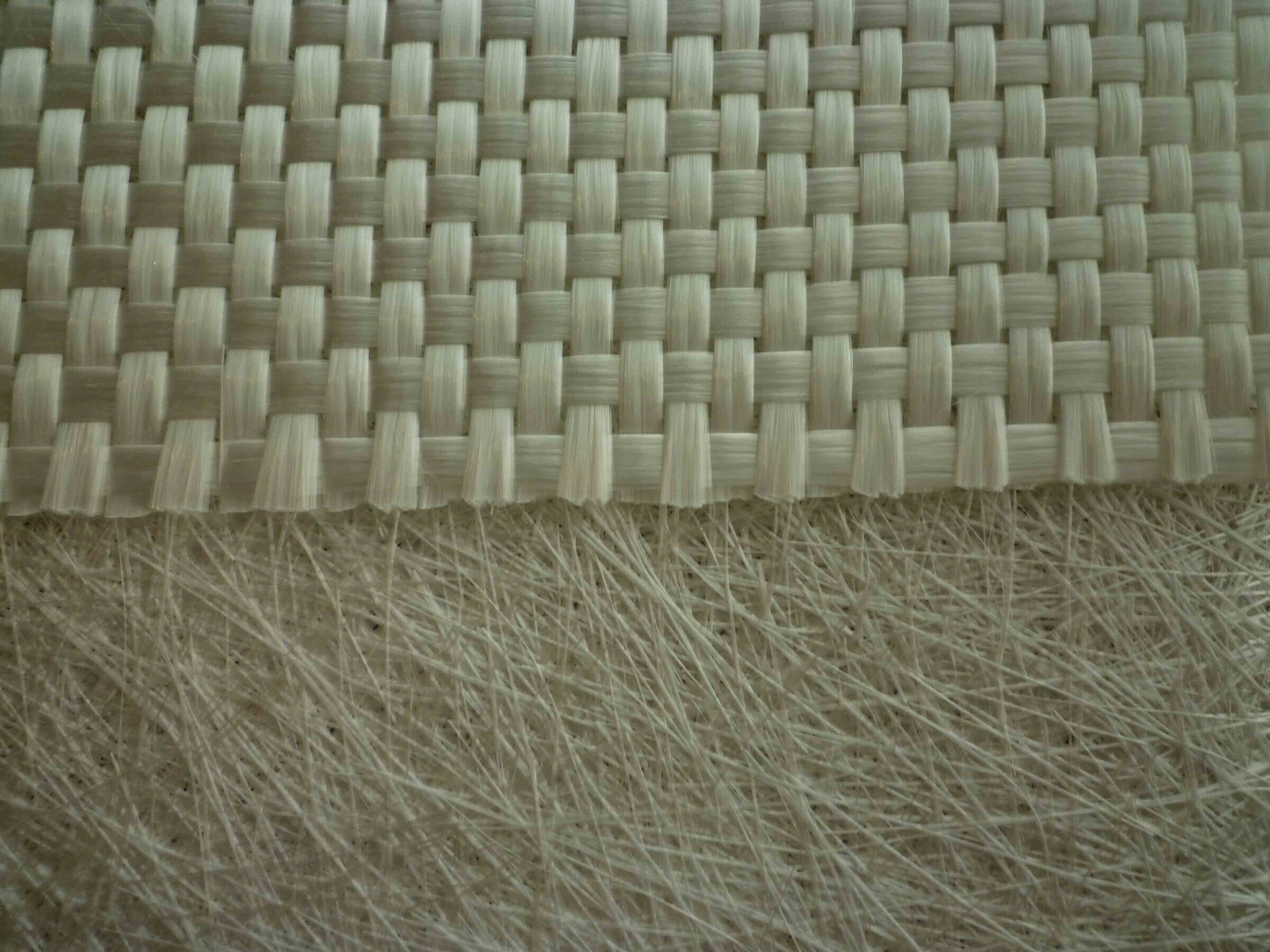

Fiberglass Reinforced Plastic (GRP) is a composite material, consisting of a resistant fiberglass structure and a plastic material that acts as a binder. It is also known as GRP or FRP. The advantages offered by this mouldable material with excellent weathering properties represent a large field yet to be exploited.

Advantages

- Customizable

- Structural strength, and excellent mechanical properties

- Unaltered by corrosion

- Lighter than steels of equivalent mechanical strength

- Thermal, electrical, and acoustic insulator

- High resistance to impact and fatigue

- Fire resistance

- Zero maintenance

- Easy handling

- Quick machining

Applications

These are used for both interior and exterior pieces, facades, and even urban furniture.

Architecture and housing are often built using conventional materials like concrete and steel. However, recent advancements in understanding the benefits of composite materials have led to their increased use in architectural design. Look Composites® has specialized in this area and has become a benchmark for projects utilizing these materials. New applications of Glass Reinforced Plastic (GRP) are emerging daily.

Interiors

The moldability and versatility of GRP finishes allow for the creation of stunning interiors, which are also easy to install.

Outdoors

With excellent weather resistance and lightweight properties, GRP is an ideal material for outdoor applications.

More than 40 years of experience in the PRFV sector

Look Composites® specializes in the manufacturing of a diverse selection of construction parts and various other components utilizing GRP, which stands for Glass Reinforced Plastic and is also referred to as PRFV. Its innovative materials empower designers to create custom pieces that are limited only by the bounds of their imagination and creativity. The versatility of GRP allows for the production of unique designs suited for a wide array of applications, ensuring that the needs of different projects can be met with precision and artistry. As a proud brand under the Miraplas umbrella, the company is backed by over 40 years of valuable experience in the GRP sector, which enables it to deliver high-quality products and services that meet the expectations of its clients. Its extensive expertise not only guarantees a reliable manufacturing process but also fosters the development of new ideas and solutions in the ever-evolving market.

Reference projects

Gazechim Composites Ibérica is constructing its new headquarters in Picassent, Spain, in collaboration with Graphenano Engineering and onside architecture. The project aims to showcase innovative nautical and aeronautical designs using advanced graphene-based composite materials. The building features an office facade designed with wave-like slats, topped by a striking "white bow" that mimics a ship's hull. This unique geometry enhances the architectural appeal, while the use of GRP (Glass Reinforced Plastic) introduces innovative possibilities previously unachievable in construction.

The interior merges traditional and modern materials to create warm, high-quality workspaces. The facility includes a custom fiberglass canopy that curves elegantly across the building. Look Composites® has developed this project using a GRP system, ensuring precision and high-quality components, with a quick installation that benefits modular construction.

Marina de Empresas is located at the Port of Valencia, specifically at Marina Real Juan Carlos I, in the former bases of the America’s Cup teams from 2003. This urban regeneration project transformed three old bases into two modern structures. A key feature is a southern circulation area that offers sea views and links two of the buildings. To withstand environmental challenges, the design utilized durable Fiber Reinforced Plastic (FRP), which has traditionally been used for buoys and boats.

The project includes two main components: the EDEM entrepreneurial school and a business accelerator formed by LANZADERA and ANGELS. The two components are connected by a communal space that invites public interaction with the seaside. Concrete pieces in the front create benches and planters, enhancing the connection between the building and the city. The renovation involved over 7,000 square meters of GRP cladding and custom sunshades, all completed in less than a year, showcasing innovation in architectural materials.

VIVOOD Landscape Hotel offers a tranquil escape for travelers seeking exclusivity and a connection with nature. Guests can enjoy peaceful walks in the valley, breathing in fresh air and embracing a sustainable lifestyle in comfort. In the evening, the hillside roads and hotel are illuminated by hundreds of lights, with moonlight reflecting on the mountains and stars twinkling in the sky—truly breathtaking. Look Composites contributed to the expansion of VIVOOD by manufacturing over 200 lightweight P.R.F.V. (Fiberglass Reinforced Plastic) palisade panels for the new villas. These panels provide privacy with a natural look and require minimal maintenance. The P.R.F.V. palisades not only enhance the exterior of the modern villas with Jacuzzis but also serve a practical purpose while allowing for easy installation.